Method and apparatus for detecting ink deposition performance of anti-counterfeit mark cover layer

An anti-counterfeiting mark and detection method technology, applied in the field of anti-counterfeiting, can solve the problems of low test accuracy, poor corrosion resistance of heat conduction plate, inability to accurately detect ink precipitation performance, etc., and achieve high control precision and good confidentiality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

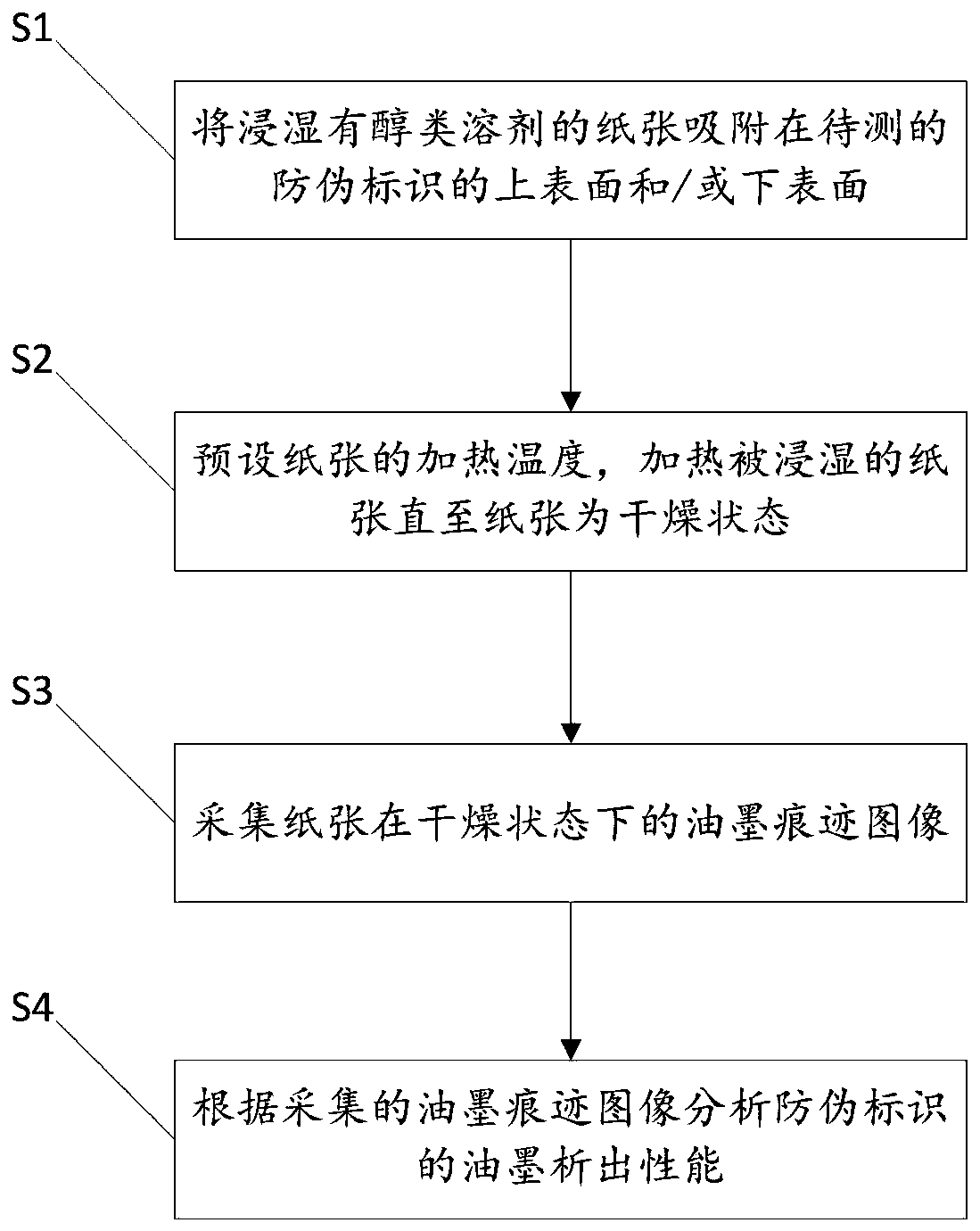

[0047] like figure 1 As shown, a method for detecting the ink release performance of the anti-counterfeiting label covering layer, the

[0048] Methods include:

[0049] Preparatory work before the test, firstly preheat the monitoring instrument of this application to the specified temperature, and cut the paper to the same size as the anti-counterfeiting label to be tested, so that the paper is cut to the same size as the anti-counterfeiting label to be tested, The size of the anti-counterfeit mark to be tested is smaller than that of the heat-resistant glass plate, so that the heat-resistant glass plate can completely cover the anti-counterfeit mark.

[0050] Step S1: Adsorb the paper soaked with alcohol solvent on the upper surface and / or lower surface of the anti-counterfeiting mark to be tested.

[0051] Step S1 includes:

[0052] S101: The automatic liquid adding device drips the alcohol solvent onto the paper to wet the paper with the alcohol solvent, and the alcohol...

Embodiment 2

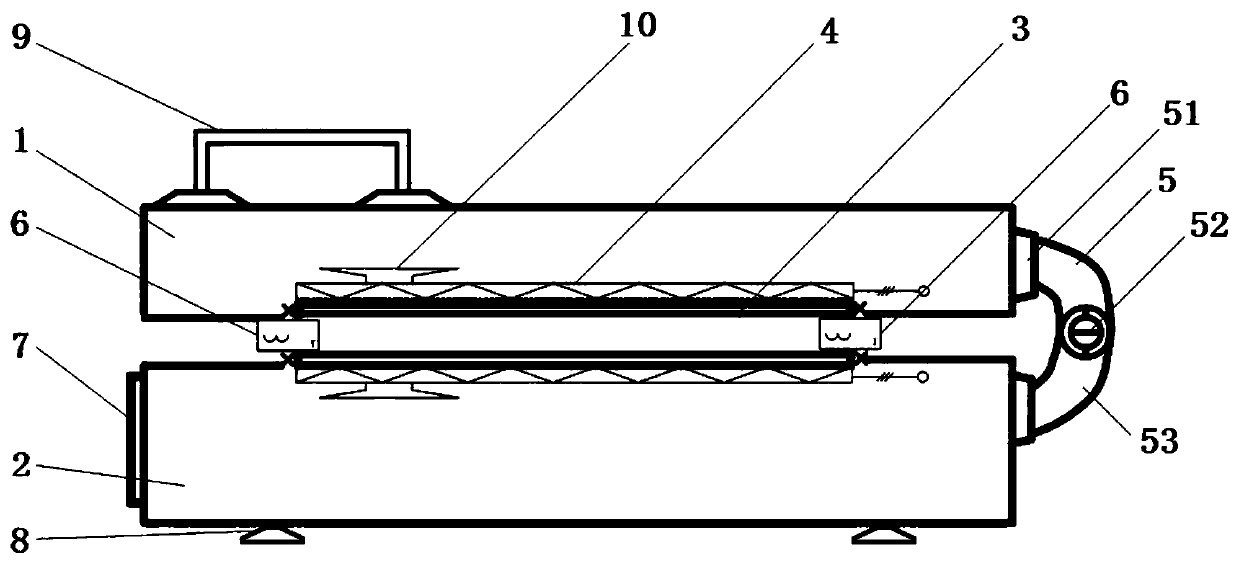

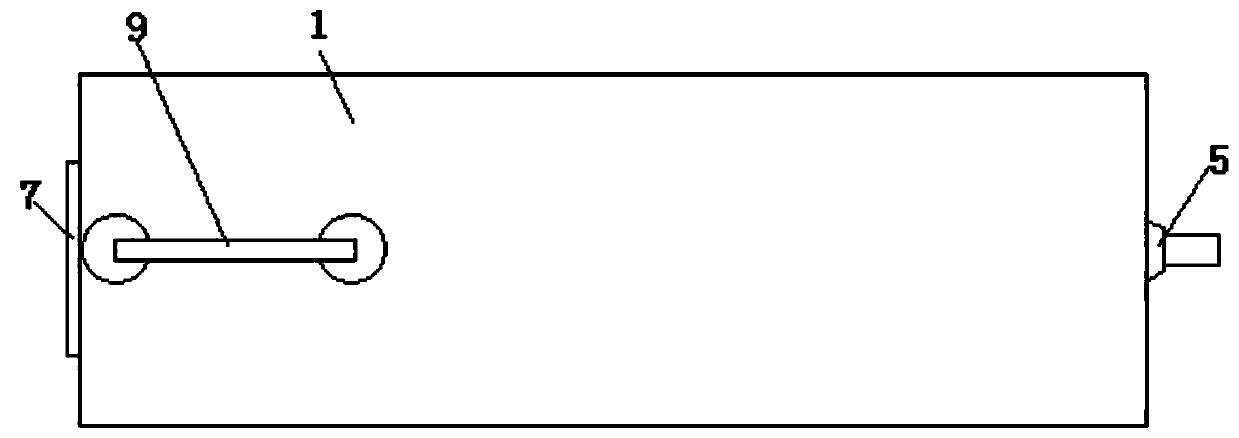

[0074] An ink precipitation performance testing instrument for the cover layer of an anti-counterfeit mark, comprising: an opening and closing gland, a heating device, an image acquisition device, and a data analysis and processing module; The paper soaked with the alcohol solvent is adsorbed on the upper surface and / or the lower surface of the anti-counterfeiting mark to be tested. like figure 2 and image 3 As shown, the opening and closing gland includes an upper gland 1 and a lower gland 2. The upper gland 1 is arranged in parallel above the lower gland 2, and one end of the upper gland 1 and the lower gland 2 is connected by a rotating member 5, and the other end is separated. When the upper gland 1 is opened, the upper gland 1 rises to a certain height relative to the lower gland 2, so that an anti-counterfeit mark to be detected can be placed between the upper gland 1 and the lower gland 2.

[0075] In this application, the upper and lower surfaces of the anti-count...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com