An all-fiber microseismic monitoring system with high sensitivity and wide frequency response

A microseismic monitoring and all-fiber technology, which is applied in measuring devices, seismic signal receivers, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of inability to achieve microseismic signal fidelity pickup, working frequency band, poor resolution, and inapplicable monitoring, etc. problem, to achieve the effect of lossless acquisition, high sensitivity, and increased quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

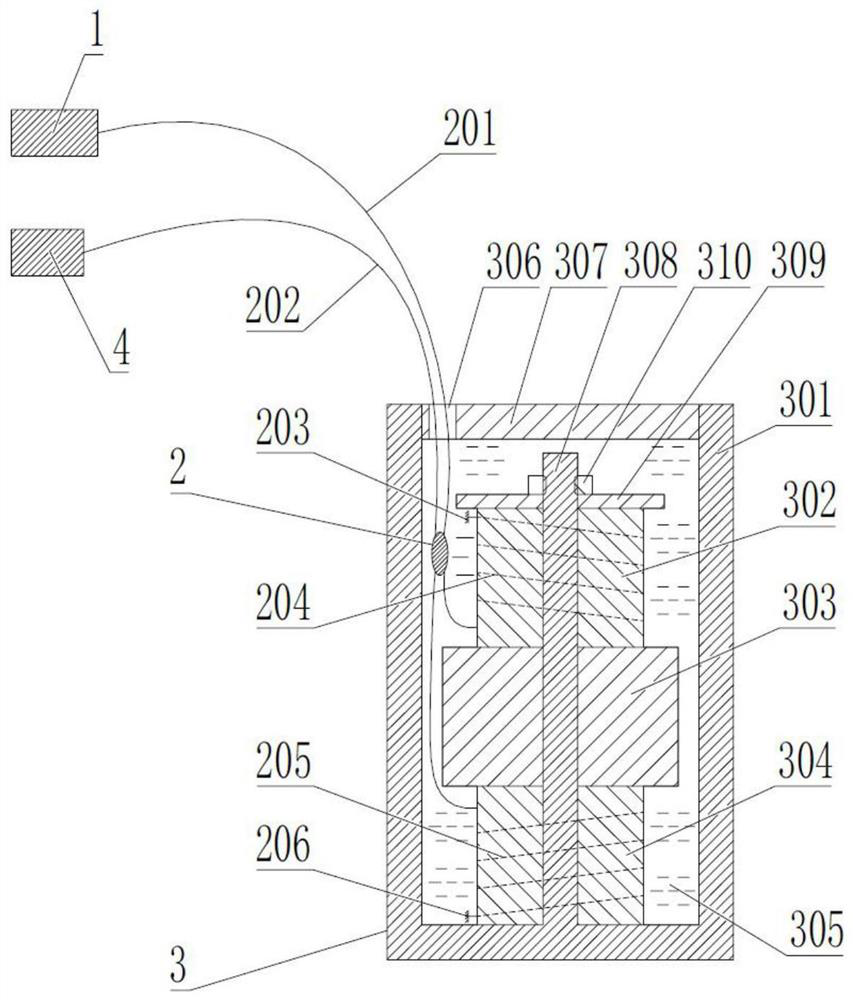

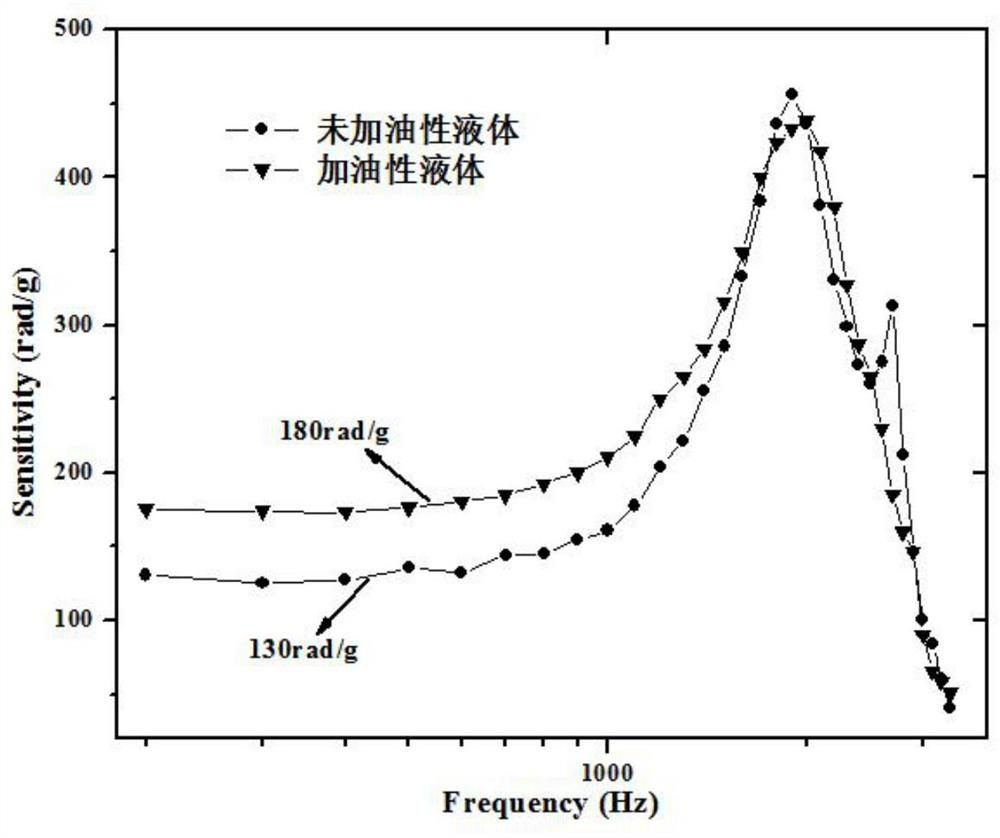

[0023] see figure 1 , a high-sensitivity wide-frequency response all-fiber microseismic monitoring system disclosed in the present invention consists of a laser light source 1 for generating laser light, a sensing probe 3 for picking up microseismic signals, and a signal demodulator for demodulating microseismic signals 4 is composed of an incident optical fiber 201 connected to the laser light source 1 and a reflective optical fiber 202 connected to the signal demodulator 4 at one end, and the sensing probe 3 is filled with an oily liquid 305 of simethicone.

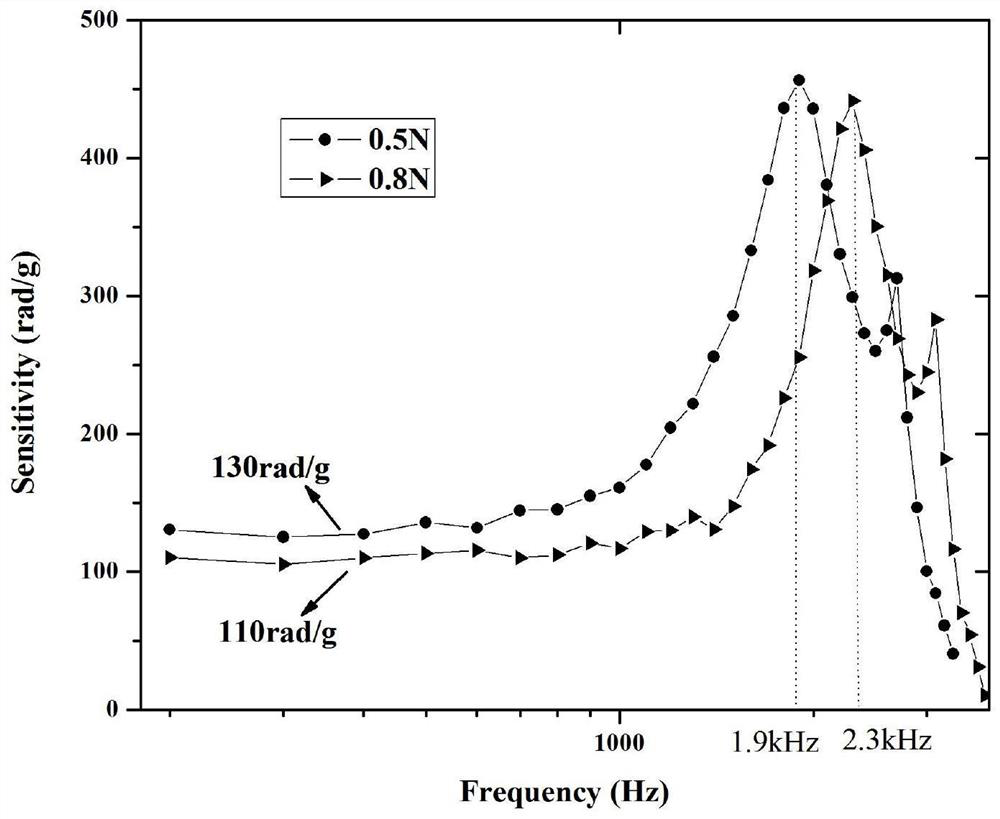

[0024] The sensor probe 3 includes a cylindrical packaging shell 301 and a top cover 307 that is threadedly connected thereto, is packaged in the packaging shell 301 and is connected to the other end of the incident optical fiber 201 and the reflecting optical fiber 202. The connected optical fiber coupler 2, the reference arm optical fiber 204 and the sensing arm optical fiber 205 drawn out from the optical fiber coupl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com