Optical lens, camera module and electronic device

A technology of optical lens and camera module, which is applied in the field of photography, can solve the problem of not being able to further meet higher-standard imaging requirements, and achieve uniform sensitivity distribution, standard refractive power distribution, and good correction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

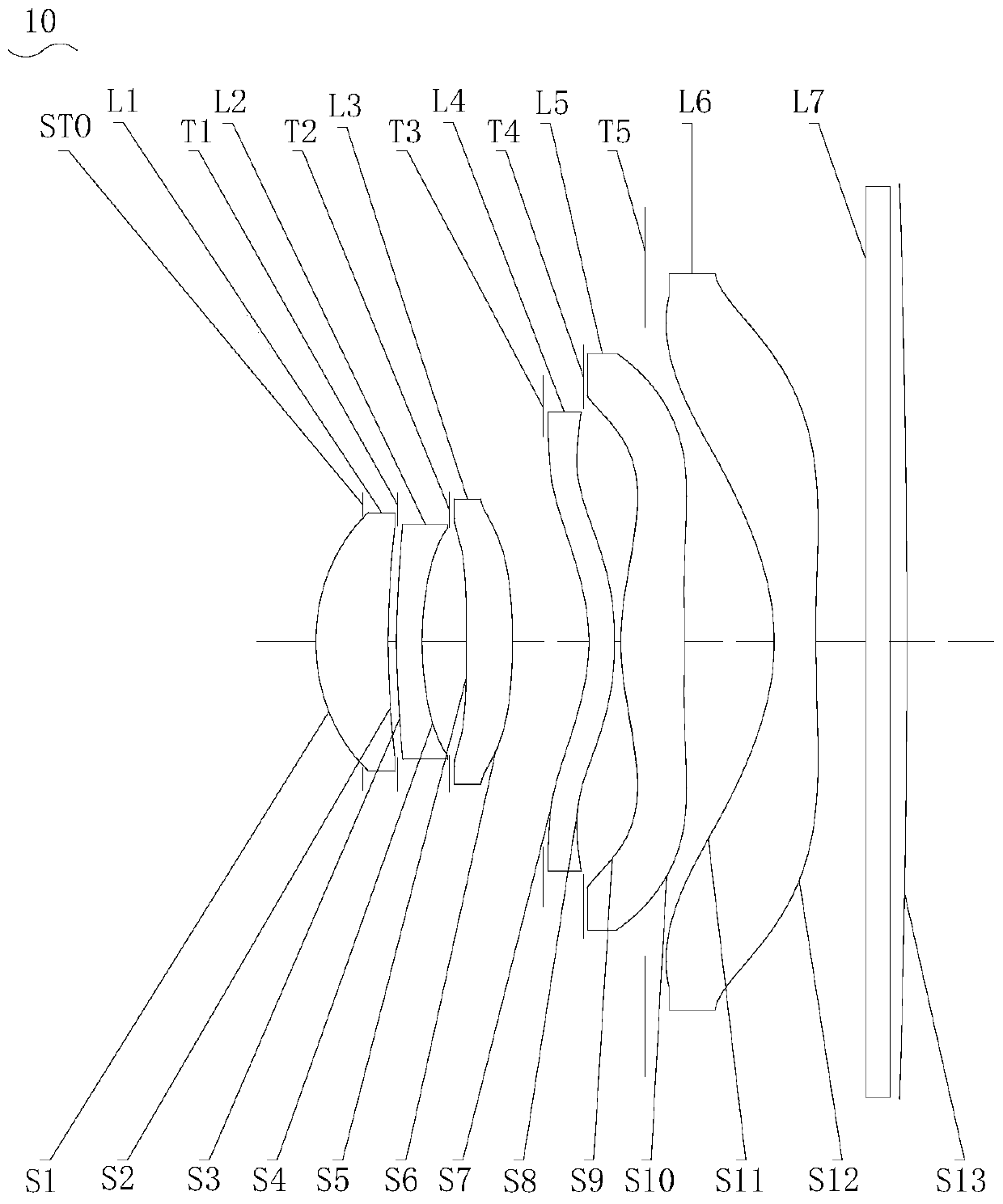

[0038] Please also refer to Figure 1 to Figure 5 The effective focal length of the optical lens 10 is EFL=4.41mm, the aperture number FNO=2.0 of the optical lens 10, half of the field of view angle of the optical lens 10 HFOV=41.6 degree, the optical total length TTL=5.19mm of the optical lens 10. The optical lens 10 satisfies the conditional formula: F2 / F1=-2.27; F3 / F1=2.63; F4 / F1=-1.52; R=-125mm; TTL / H=0.64. The optical lens 10 also meets the following table conditions:

[0039] Table 1

[0040]

[0041] Table 2

[0042]

[0043]

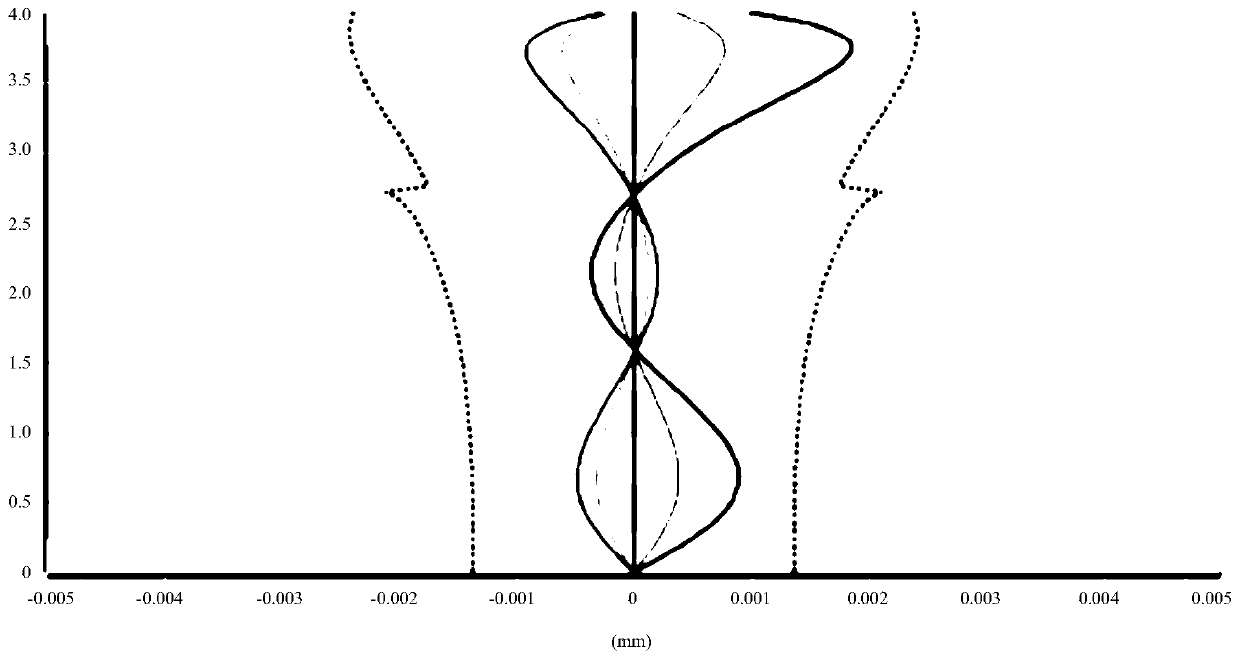

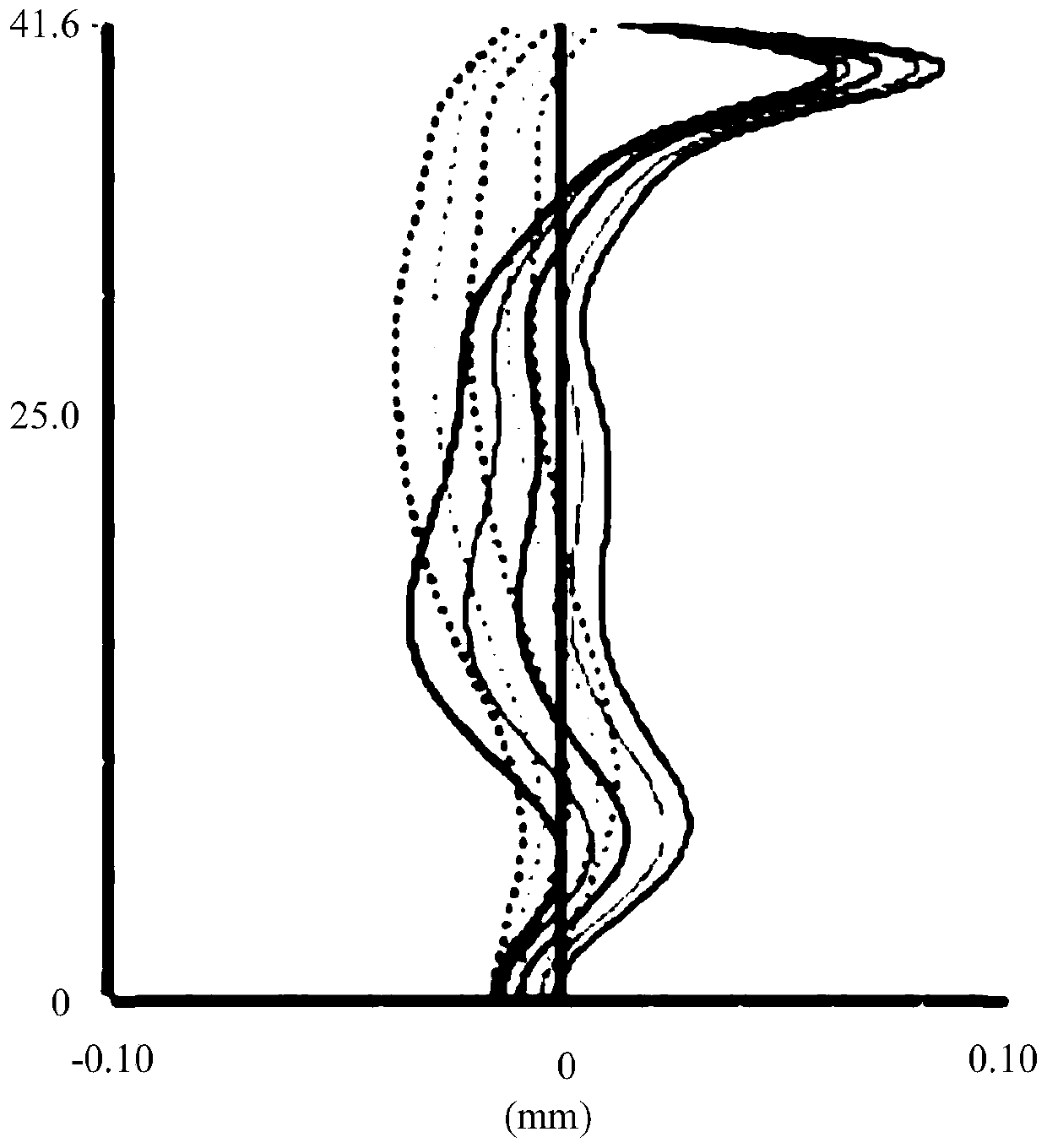

[0044] Depend on figure 2 It can be seen that the longitudinal chromatic aberration is controlled within ±0.002mm, and the aberration correction effect of the optical lens 10 is better. Depend on image 3 It can be seen that the full field of view of the field curvature is controlled within ±0.1mm, which optimizes the field curvature and improves the imaging quality. Depend on Figure 4 It can be seen that when the optical distor...

no. 2 approach

[0046] Please also refer to Figure 6 to Figure 10 , the effective focal length of optical lens 10 is EFL=4.45mm, the aperture number FNO=2.2 of optical lens 10, the half HFOV=41.7 degree of the field angle of optical lens 10, the optical total length TTL=5.2mm of optical lens 10. The optical lens 10 satisfies the conditional formula: F2 / F1=-2.25; F3 / F1=2.674; F4 / F1=-1.5; R=-137mm; TTL / H=0.651. The optical lens 10 also meets the following table conditions:

[0047] table 3

[0048]

[0049]

[0050] Table 4

[0051]

[0052] Depend on Figure 7 It can be seen that the longitudinal chromatic aberration is controlled within ±0.002mm, and the aberration correction effect of the optical lens 10 is better. Depend on Figure 8 It can be seen that the full field of view of the field curvature is controlled within ±0.1mm, which optimizes the field curvature and improves the imaging quality. Depend on Figure 9 It can be seen that when the optical distortion is less tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Optical length | aaaaa | aaaaa |

| Optical length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com