Method of manufacturing spectacle lens for reducing chamfer imaging interference

The technology of a spectacle lens and a manufacturing method, which is applied in the field of glasses, can solve problems such as chamfering imaging interference, and achieve the effect of reducing visual interference and improving wearing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

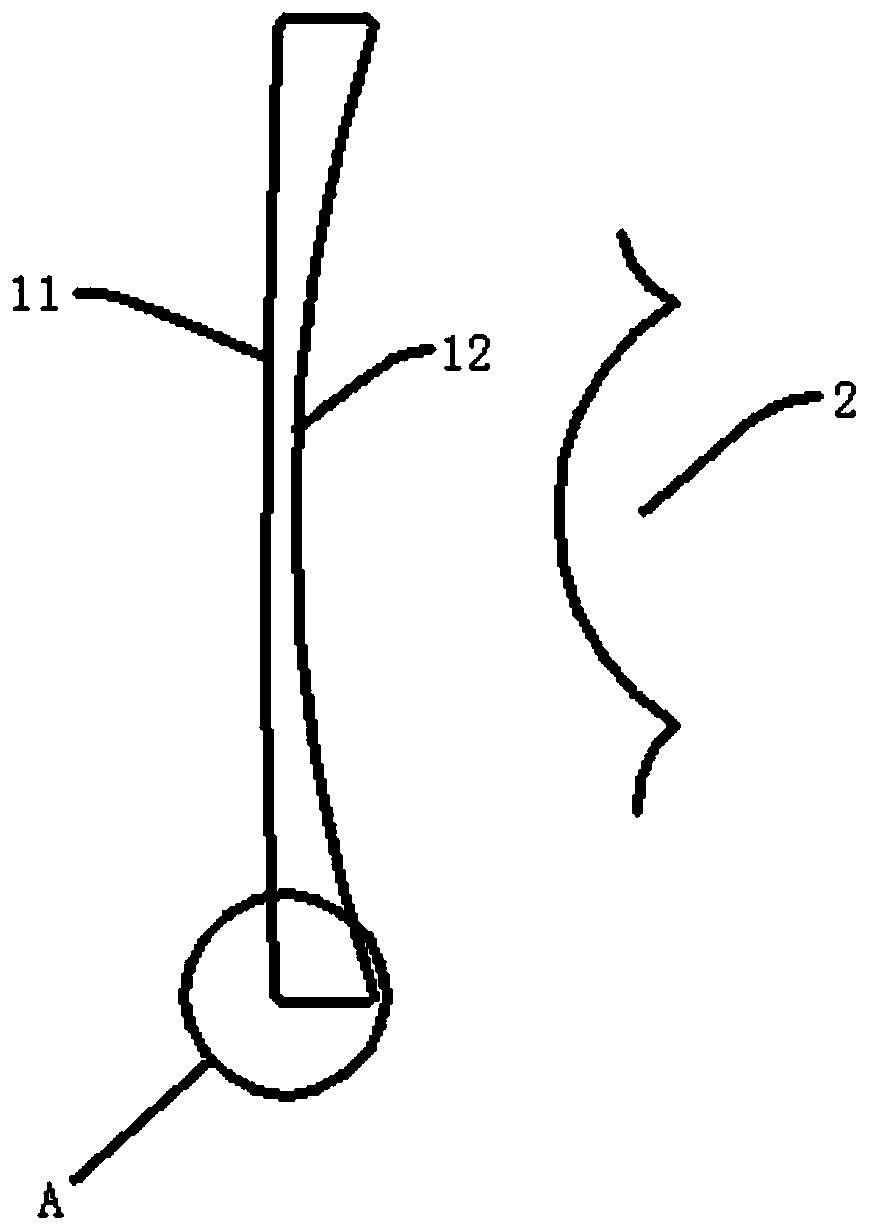

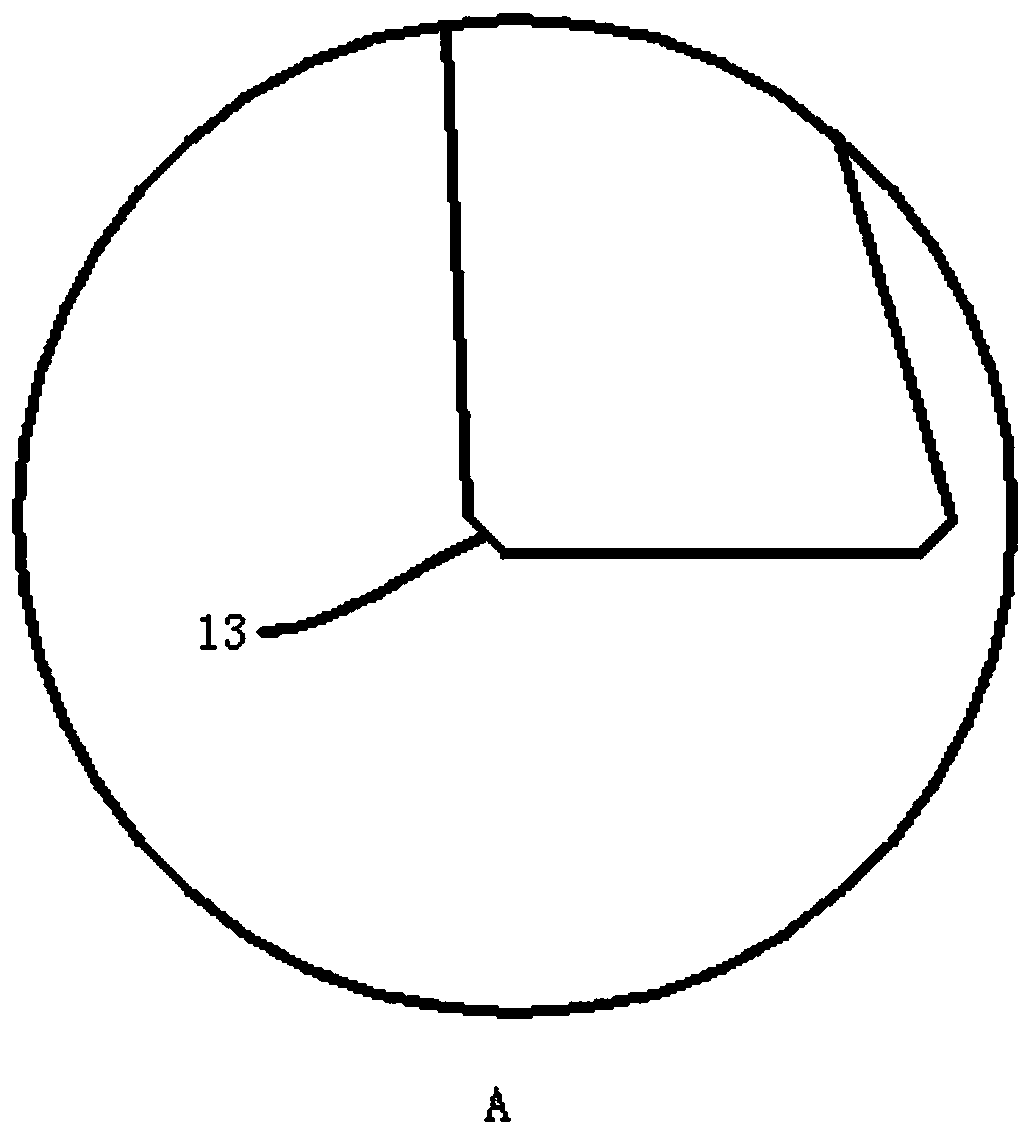

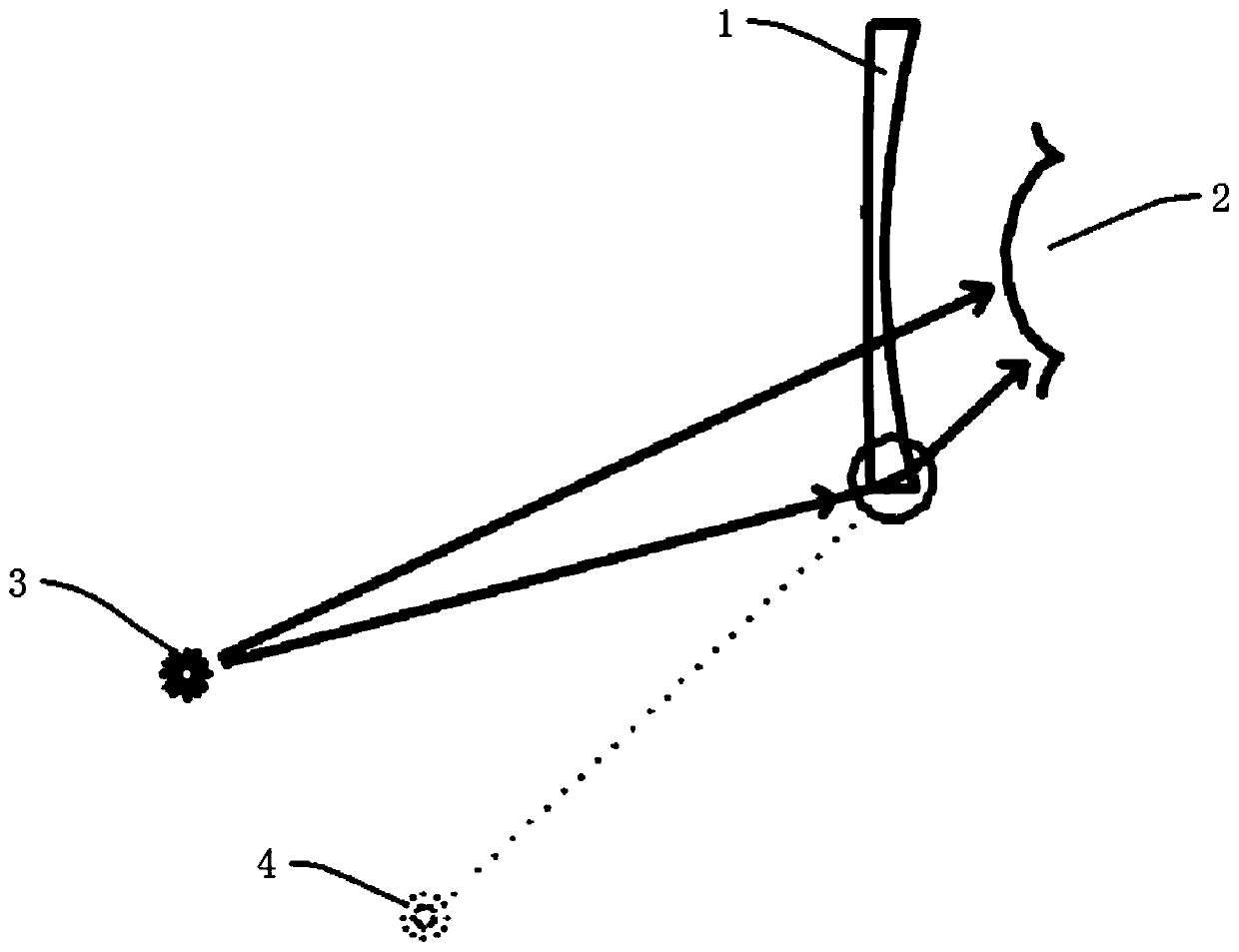

[0043] Such as figure 1 and figure 2 As shown, a method for manufacturing spectacle lenses that reduces chamfered imaging interference, the specific method is to reduce the light emitted by the light spot from entering the eye from the chamfer by changing the structure of the edge chamfer 13 on the side of the spectacle lens 1 away from the eye pupil 21 The intensity of the pupil 21.

[0044] The production of glasses requires many delicate processes. Due to cutting, the edges of the lenses become sharp and sharp, which poses a safety hazard, so the chamfering of the concave and convex surfaces is an essential operation. Such as Figure 3-1 to Figure 3-3 As shown, taking the lens of myopia glasses as an example, because of the existence of chamfer 13 on the convex edge of the lens, there are two paths for the light emitted from the surface of the front object to enter the eye 2, so the eye 2 will see two kinds of images: ① light emission → Convex surface 11→mirror body→con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com