Piston for internal combustion engine and manufacturing method therefor

A manufacturing method and technology of an internal combustion engine, applied in the directions of internal combustion piston engines, pistons, combustion engines, etc., can solve the problems of temperature reduction and fuel gasification deterioration, and achieve the effect of reducing pollutants and improving thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

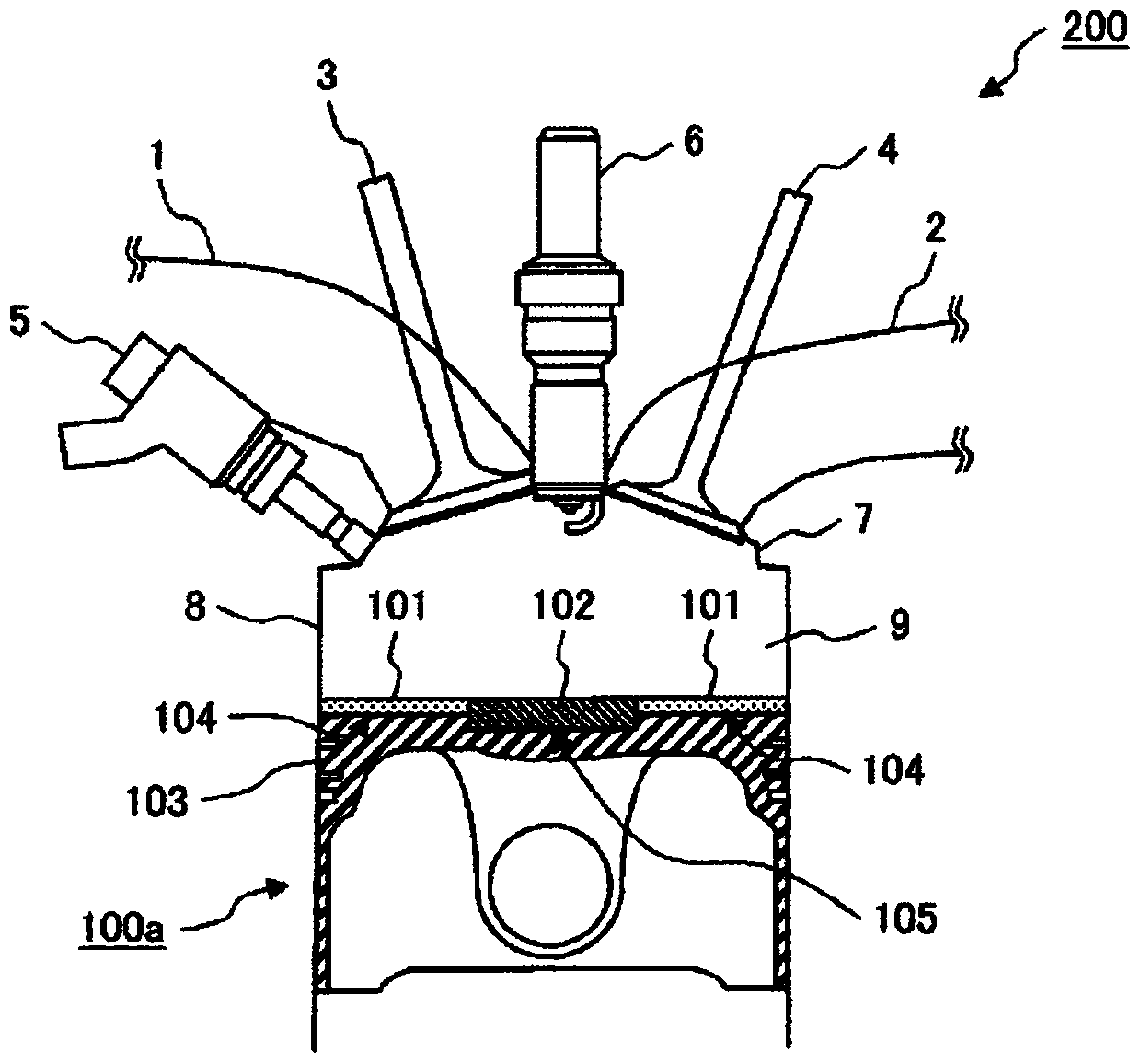

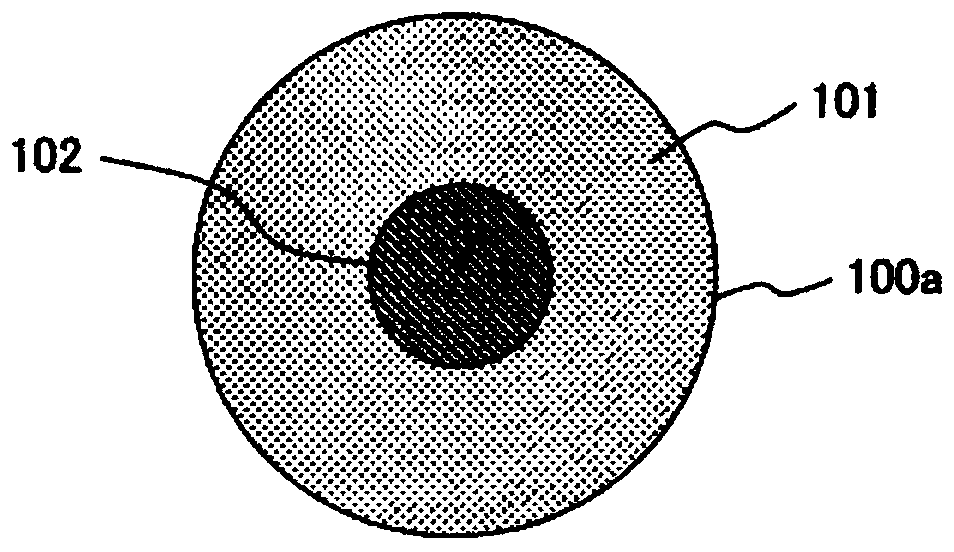

[0050] Hereinafter, embodiments of the present invention will be described in detail using the drawings.

[0051] 1. Basic idea of the present invention

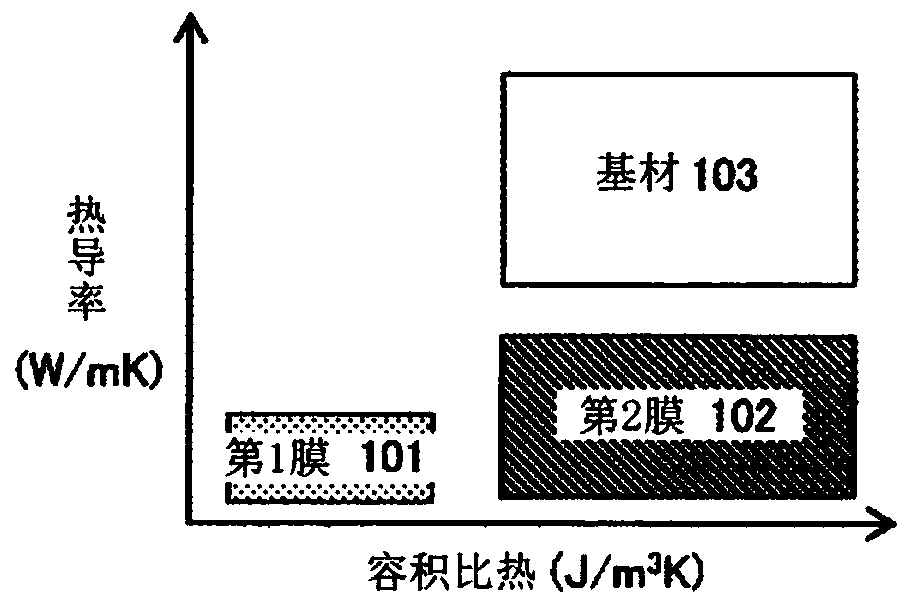

[0052] Figure 21 It is a schematic diagram showing a cross-section of a conventional piston for an internal combustion engine. Such as Figure 21 As shown, the piston 100' of the prior art (Patent Document 1) is provided with an anodized film 101' of low thermal conductivity and low heat capacity on the surface of a base material 103', and on a part of the surface of the anodized film 101' (The fuel injection region) is provided with a metal coating 102' having a heat capacity relatively higher than that of the anodized coating 101'. That is, the anodized film 101' and the metal film 102' are stacked on the surface of the base material 103'.

[0053] Figure 22 to represent having Figure 21 Graph showing temperature changes on the surfaces of the anodized film 101' and the metal film 102' within one cycle of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com