Systems and methods for rotating and translating a substrate in a process chamber

A technology of substrates and rotating parts, applied in the field of systems and methods for rotating and translating substrates in process chambers, can solve the problems of increased cost, increased process performance, etc., achieve clean wiring management, eliminate requirements, reduce effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

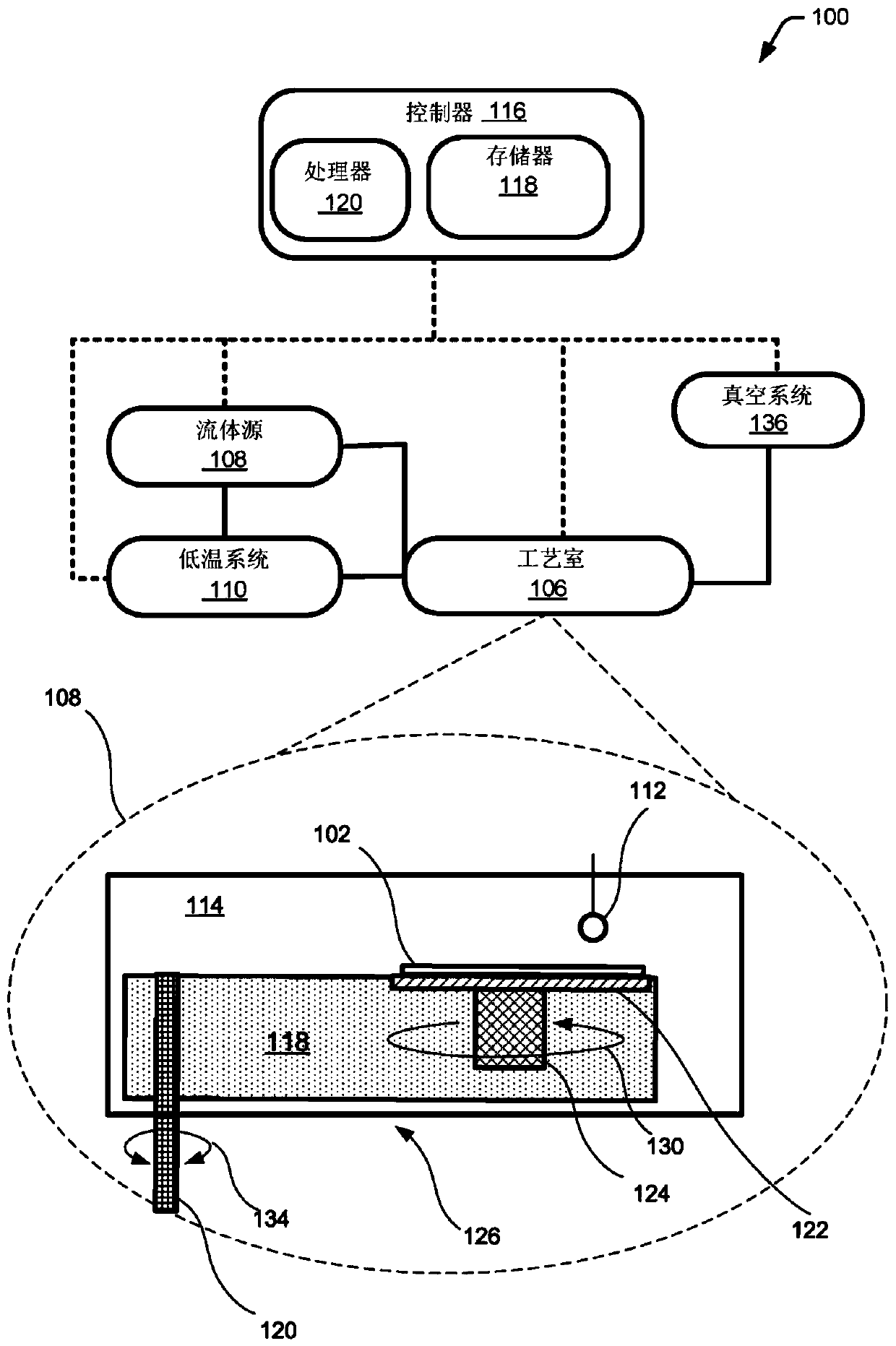

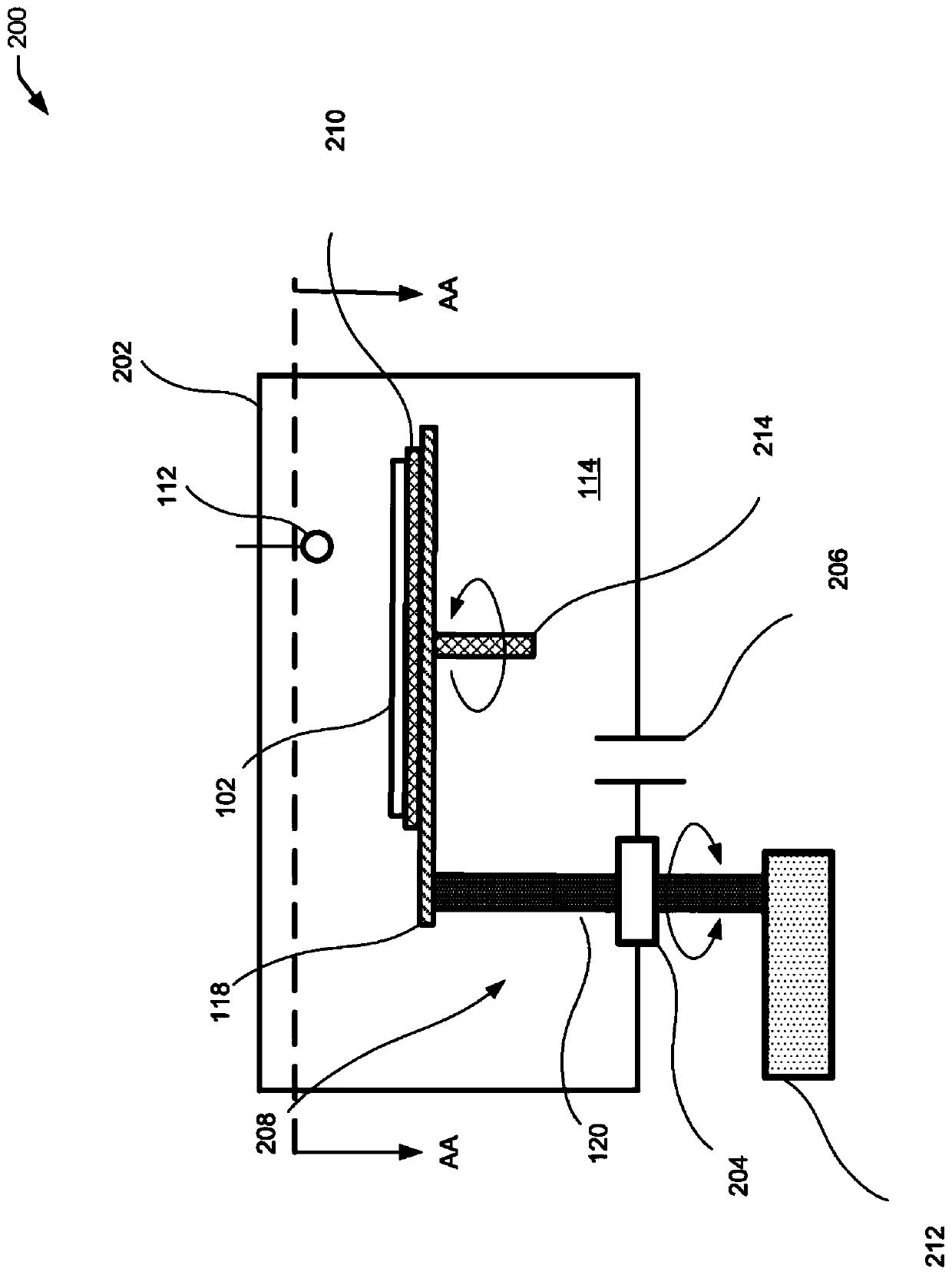

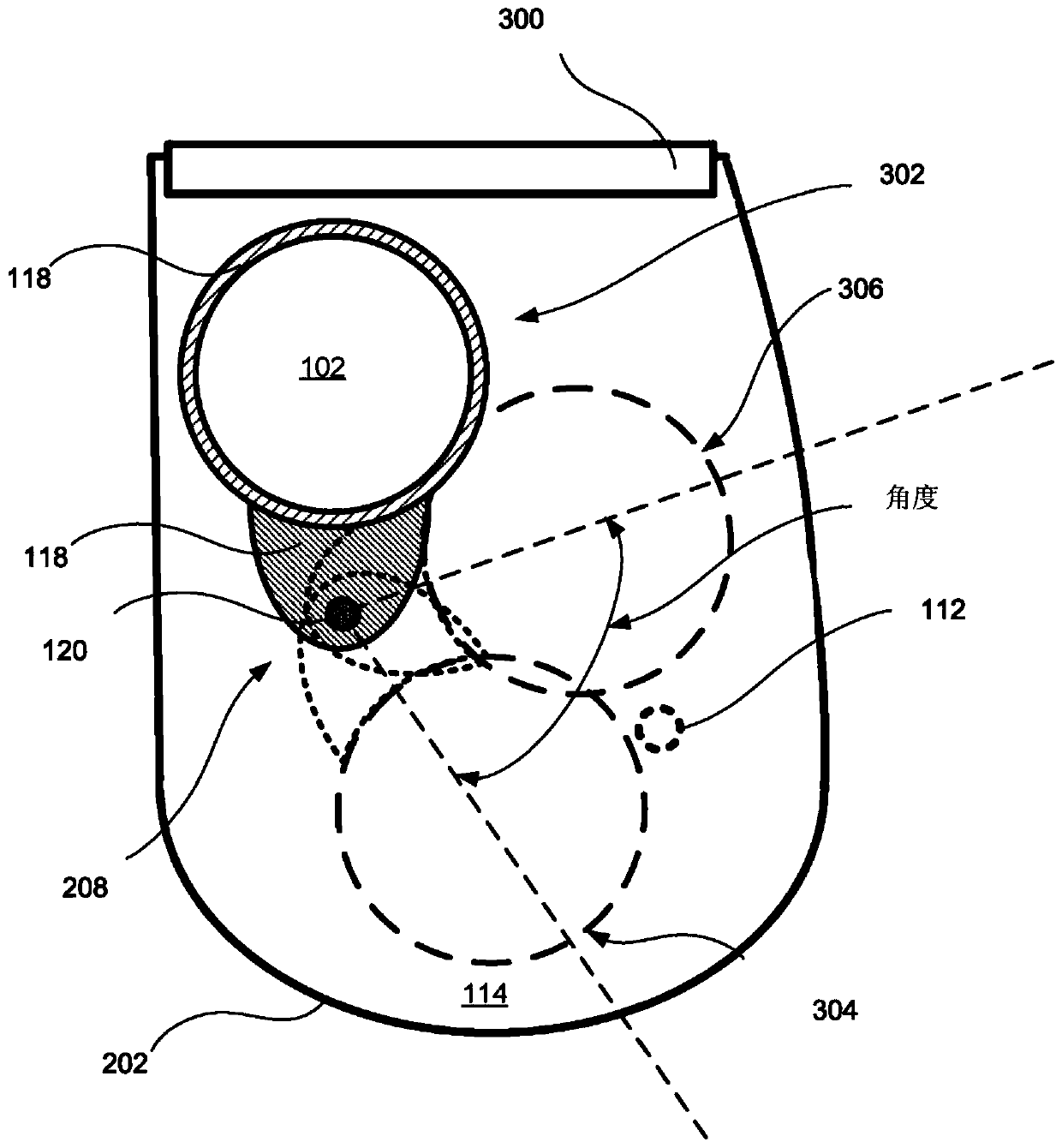

[0019] figure 1 A schematic diagram of an exemplary processing system including processing a microelectronic substrate by moving the substrate in a chamber in a unique manner relative to a dispensing source. In particular, in embodiments pertaining to a single distribution source with a concentrated fluid flow capable of processing discrete portions of a substrate such that moving the substrate improves wafer processing results. However, the processing system is not limited to single dispense source processing, and can be used with multi-source dispense processing to achieve more uniform chemical processing (eg, cleaning, deposition, etching, etc.). The treatment system is described as a low temperature cleaning system for exemplary and descriptive purposes, but is not intended to limit the scope of the claims to cleaning implementations. For example, the systems and methods disclosed herein may be applied to deposition, etching, tracking, metrology, patterning, or any other ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap