Paper-making process reconstituted tobacco shredding method capable of determining length and width accurately

A technology for reconstituting tobacco leaves and making paper, which is applied in the directions of tobacco, tobacco processing, application, etc., can solve problems such as inability to adjust the length and width of paper filaments, and achieve the effect of ensuring product quality, simple and compact structure, and uniform length and width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

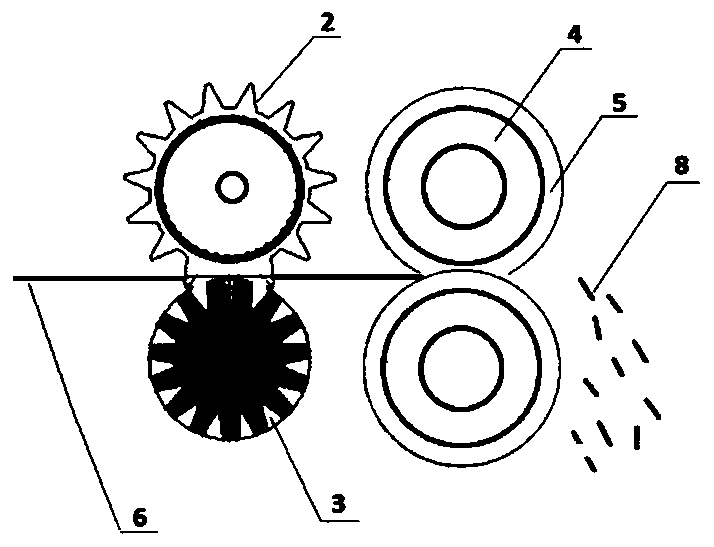

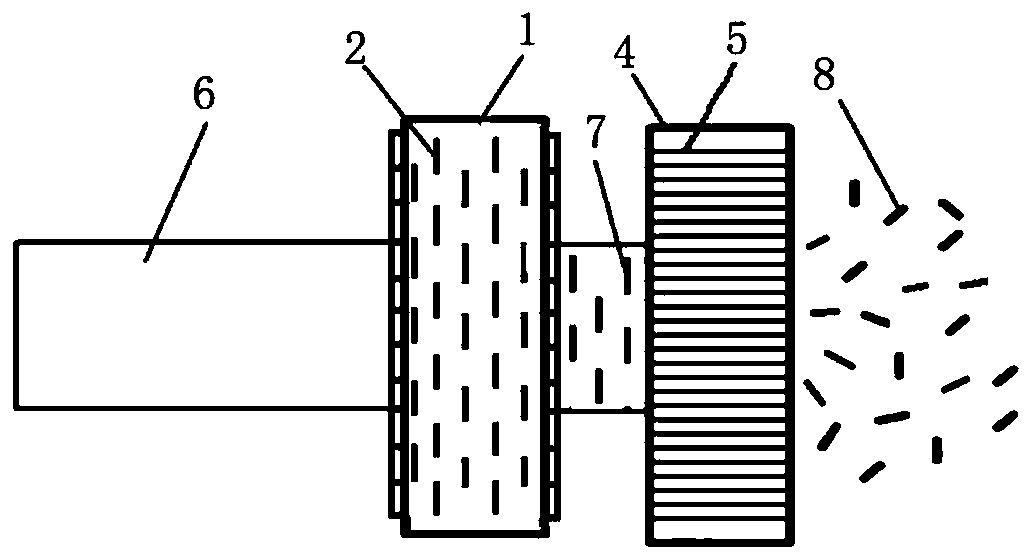

[0022] A method of shredding reconstituted tobacco leaves by the papermaking method that can accurately determine the length and width, such as Figure 1-Figure 5 As shown in the figure, the reconstituted tobacco leaves are slit by sequentially arranged cross-cutting knife group and longitudinal cutting knife group.

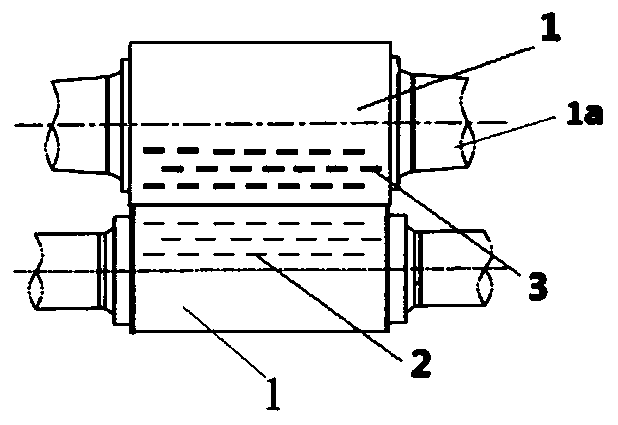

[0023] Such as image 3 As shown, the cross-cut knife group is composed of two upper and lower cross-cut knife rolls 1 paired, and a protruding strip-shaped blade group 2 arranged along the axial direction of the knife roll is provided on the surface of one of the cross-cut knife rolls. The surface of the cross cutter roller is provided with a concave blade groove group 3 corresponding to the position of the strip blade group. The transverse knife edge group arranged on the surface of the cross-cutting knife roll is a plurality of groups of strip-shaped blades arranged in parallel along the length of the cross-cutting knife roll and evenly distributed around the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com