Recognition method of turbulence device of food processing machine

A technology of a food processor and a turbulence device, which is applied to household appliances, applications, kitchen utensils, etc., can solve the problems of unreliable fixing of the turbulence device, poor crushing, and the blade cannot hit the material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

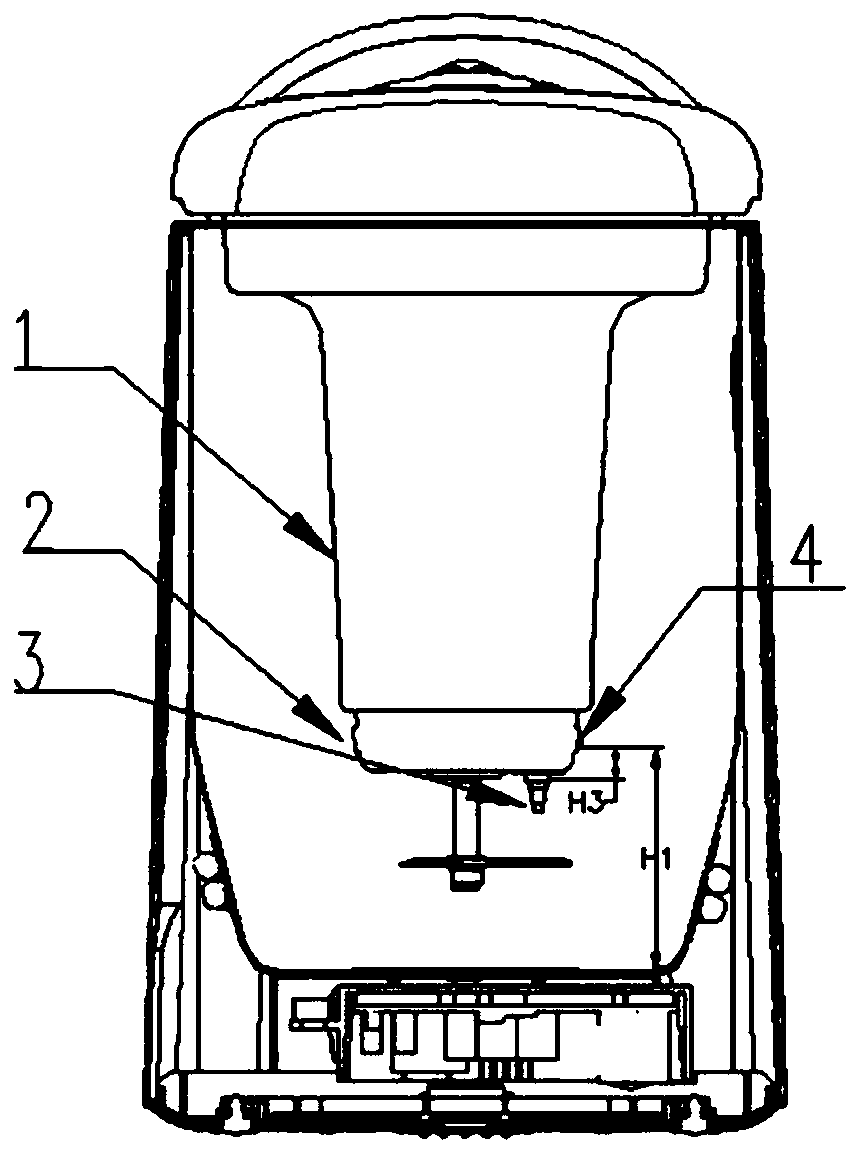

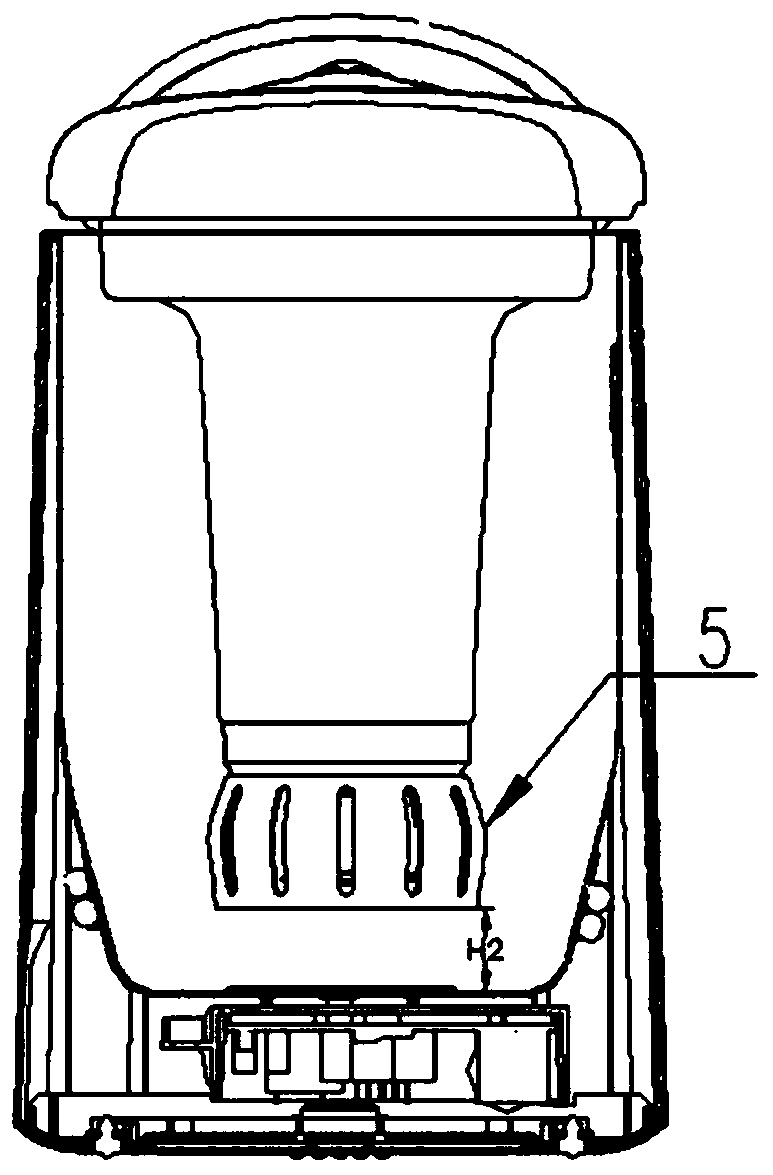

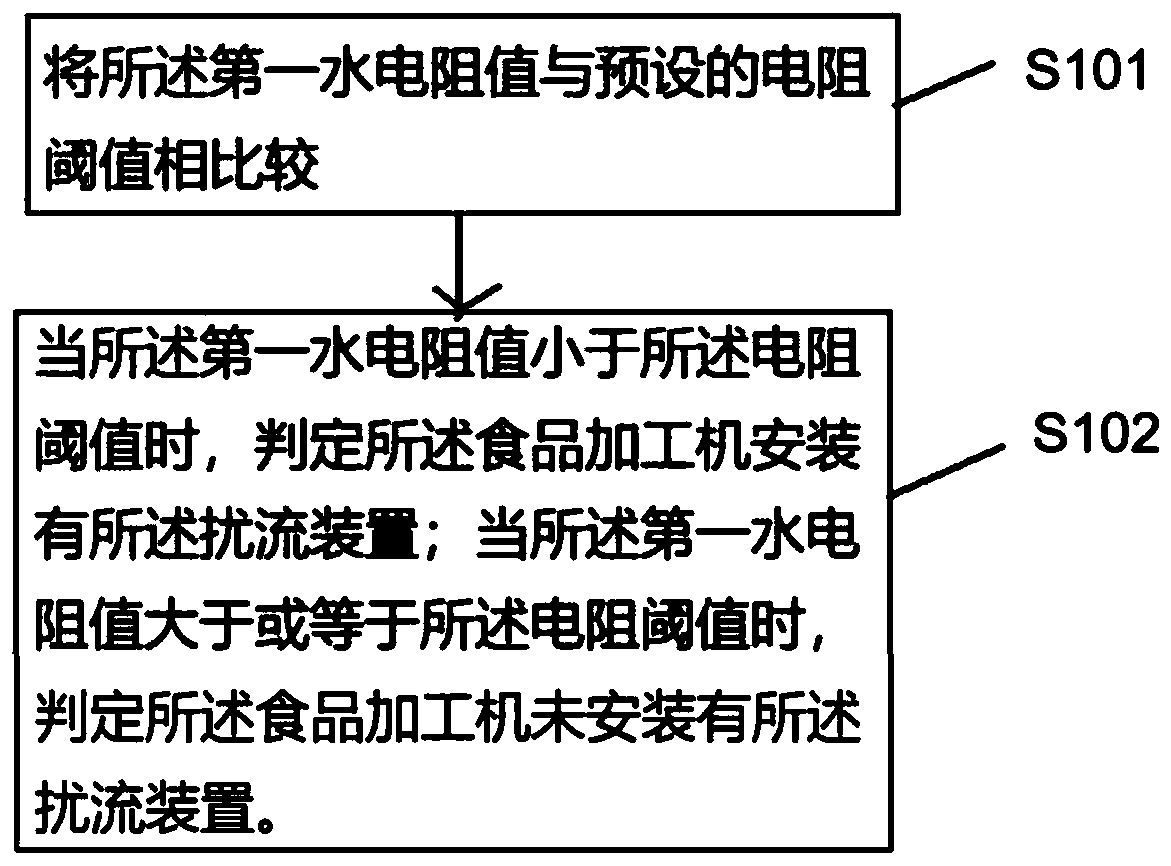

[0039] An embodiment of the present invention provides a method for identifying a spoiler of a food processor, as shown in Figure 1(a) and Figure 1(b), the spoiler 5 is detachably installed, and the spoiler 5 can be set on the lower cover 1 of the machine head of the food processing machine, and the position 2 of the flow turbulence device 5 is provided with a flow turbulence device detection electrode 4, and the flow turbulence device detection electrode 4 can be used to detect all The turbulence device detects the first water resistance value between the electrode 4 and the inner wall of the cup (for example, the inner wall of the cup bottom) of the food processor; wherein, when the food processor is equipped with the turbulence device 5 , the flow disturbance device detection electrode 4 is electrically connected to the flow disturbance device 5; as figure 2 As shown, the method may include S101-S102:

[0040]S101. Comparing the first water resistance value with a preset r...

Embodiment 2

[0048] On the basis of the first embodiment, this embodiment provides the combined judgment of the head water level detection electrode 4 and the detection electrode of the spoiler 5, the resistance value between the two electrodes is used as the calibration value, and the embodiment scheme of adaptively adjusting the resistance threshold .

[0049] In an exemplary embodiment of the present invention, the food processor may further include a water level detection electrode; the water level detection electrode is used to detect the water level in the cup of the food processor;

[0050] The method may further include: correcting the resistance threshold according to a second water resistance value between the flow disturbing device detection electrode and the water level detection electrode.

[0051] In an exemplary embodiment of the present invention, the presence or absence of the spoiler can be detected when the user selects a function, and the system can first detect the wat...

Embodiment 3

[0067] In this embodiment, on the basis of the first or second embodiment, the installation position of the detection electrode 4 of the flow disturbance device is limited.

[0068] In an exemplary embodiment of the present invention, the distance between the water level detection electrode and the flow disturbance device may be equal to the distance between the flow disturbance device detection electrode and the water level detection electrode.

[0069] In an exemplary embodiment of the present invention, the flow disturbance device detection electrode 4 can be arranged at a position close to the water level detection electrode 3, and the distance between the water level detection electrode 3 and the flow disturbance device 5 can be compared with the distance between the flow disturbance device detection electrode 4 and the water level detection electrode 4. The electrodes 3 are at the same distance, which may be H3.

[0070] In an exemplary embodiment of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com