Dust suppression device for railways

A railway and end frame technology, applied in separation devices, railway auxiliary equipment, use of liquid separators, etc., can solve the problems of polluting the surrounding environment, no special railway dust suppression device, etc., to achieve dust suppression, compact structure, and complete functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

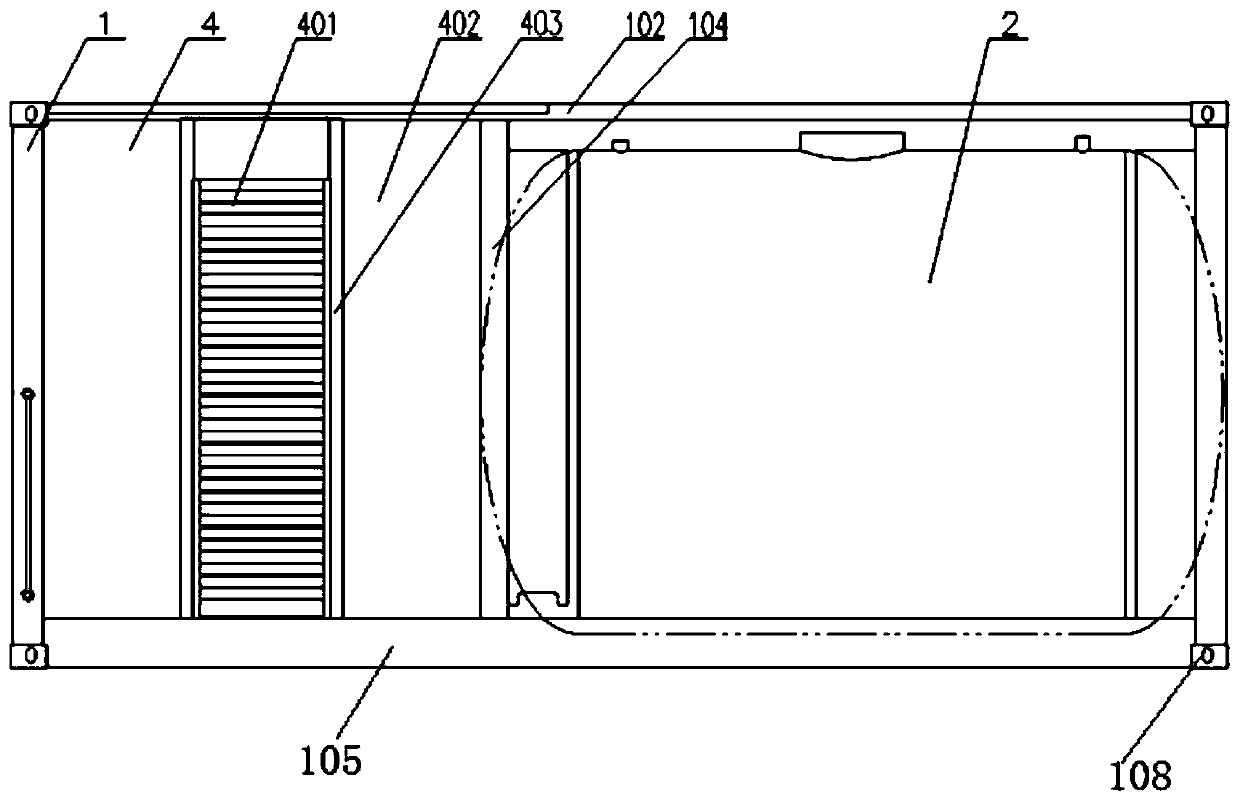

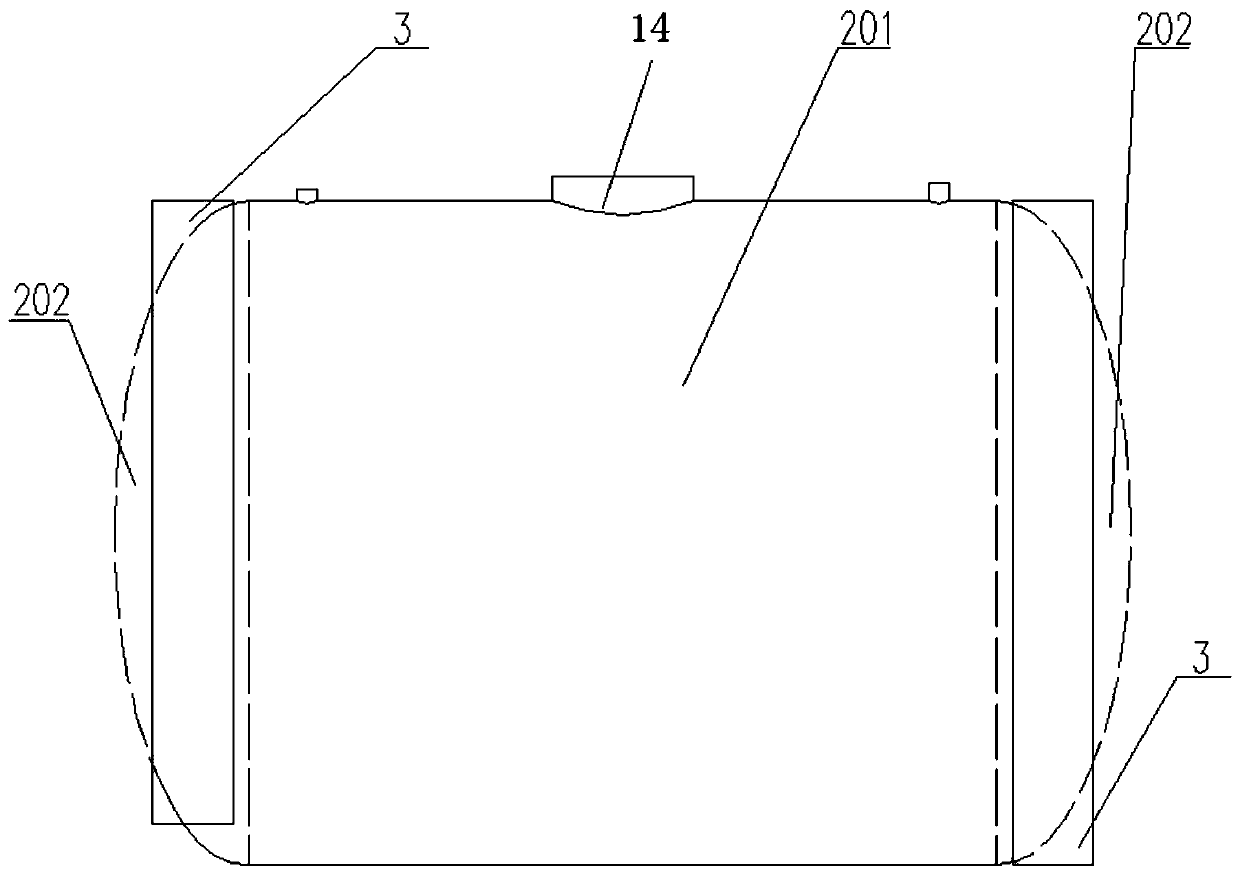

[0072] Such as Figure 1-Figure 10 As shown, the railway dust suppression device includes a support frame 1, a tank body 2 and an operation room 4; the operation room 4 is provided with a water supply unit 5, a sprinkler unit 8, a control unit and a power supply unit.

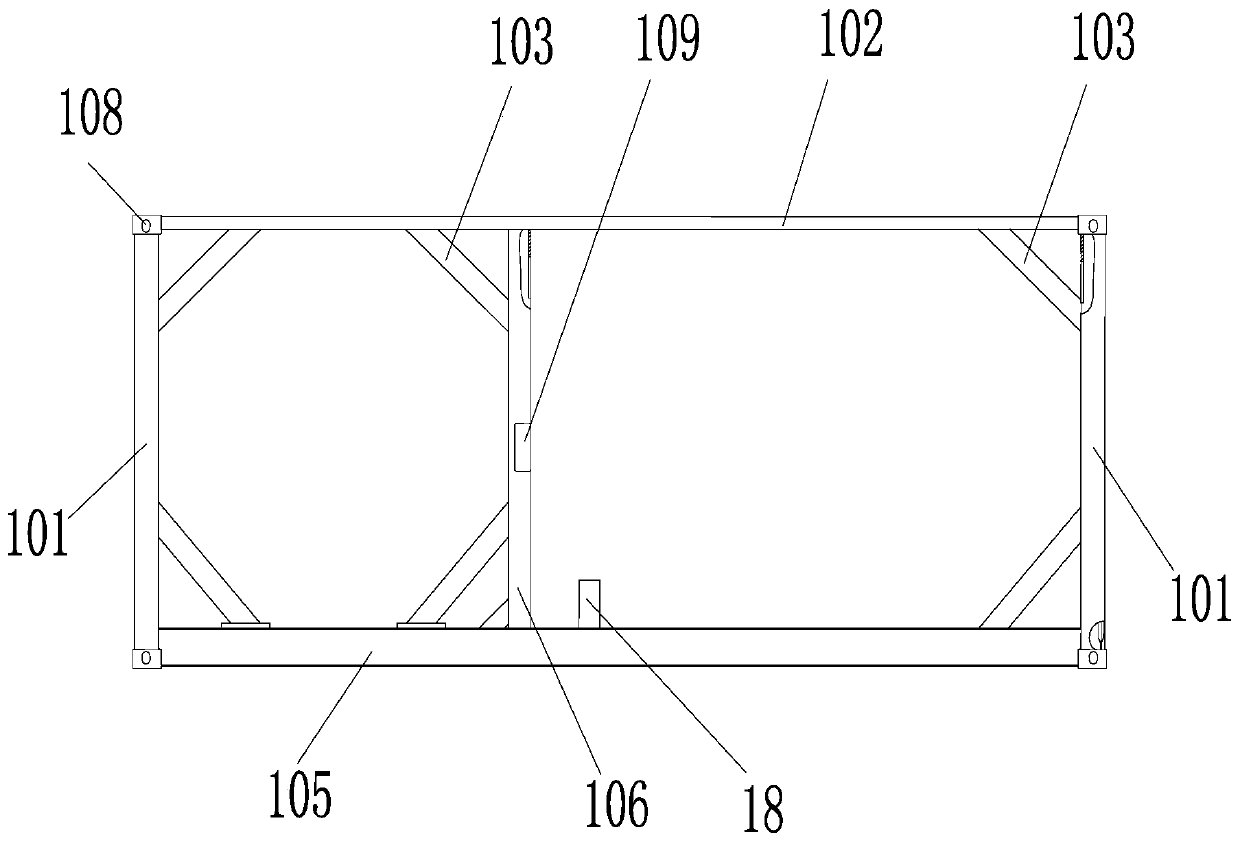

[0073] The support frame 1 includes two square end frames, two upper beams 102 and two lower beams 105 connecting the corresponding vertices of the two square end frames, and a plurality of braces 103 to enhance the strength and rigidity of the support frame 1 . Among them, the two lower beams 105 are made of I-beam; the upper beam 102 is made of square steel, and the upper and lower vertices of each end frame are welded with special corner fittings 108 for containers, which are used for shipping and lifting devices. The lock seat is directly matched and fixed, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com