Feeding device for fused deposition type 3D printer and corresponding implementation method

A technology of 3D printers and feeding devices, applied in 3D object support structures, metal processing equipment, manufacturing tools, etc., can solve the problem of filament deformation, shallow tooth marks, elastic pressing structure, etc. It is difficult to find the best balance point for different materials, etc. problem, to achieve the effect of increasing the maximum output torque and limit wire feeding thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the following, the feeding device for the fused deposition 3D printer of the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand the technical idea claimed by the present invention more clearly.

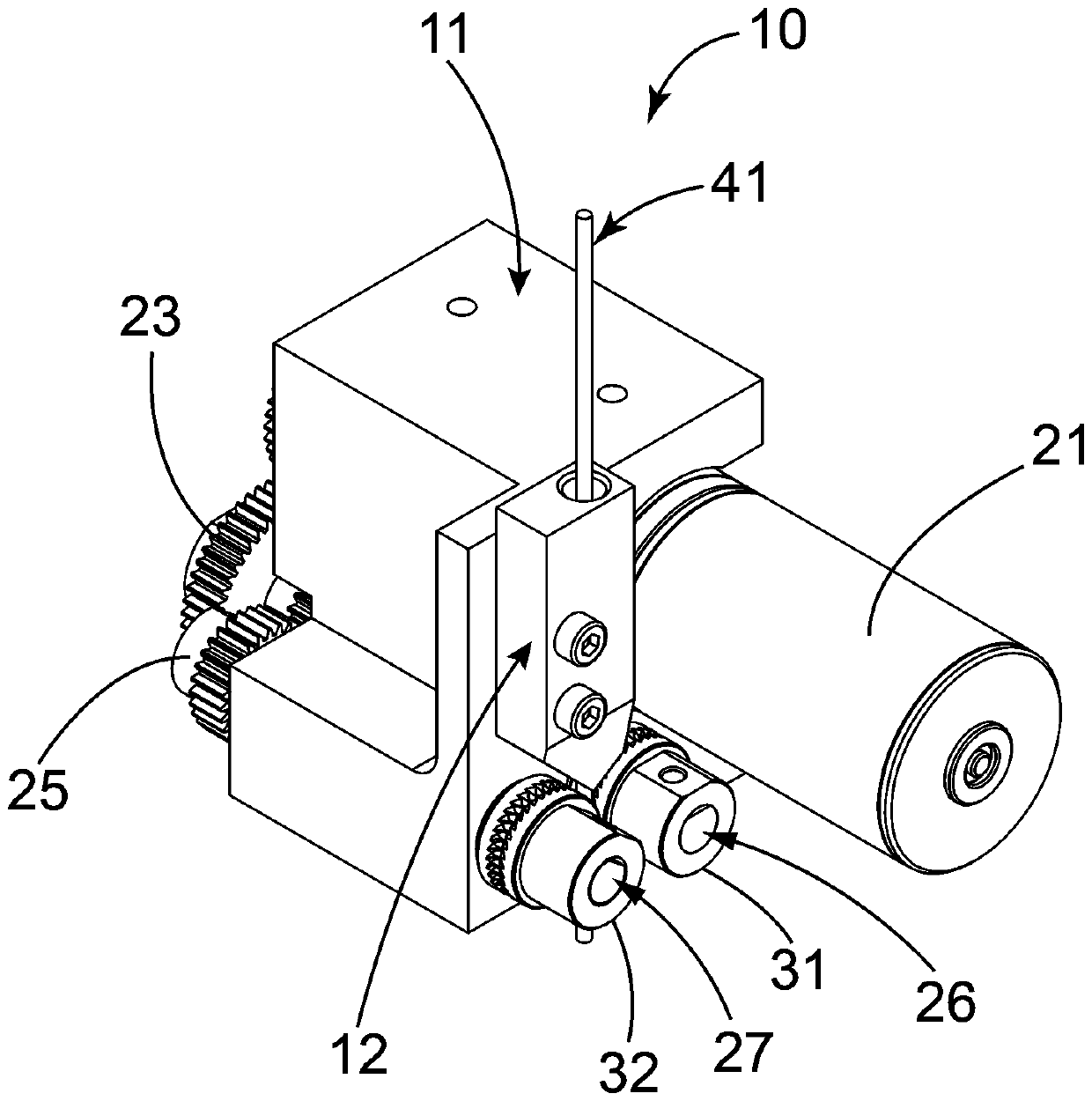

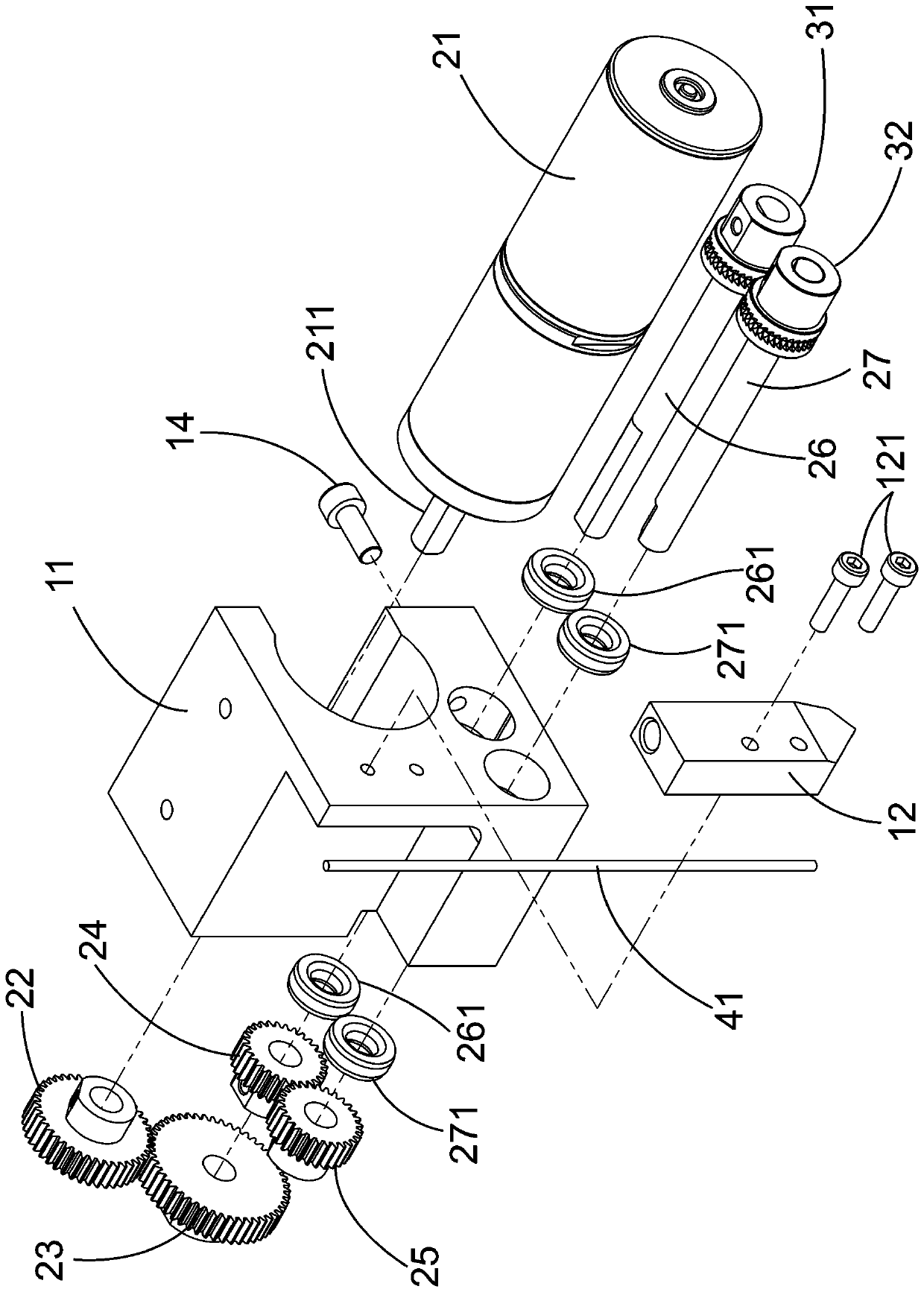

[0041] figure 1 and figure 2 An assembled and disassembled structural perspective view of an embodiment of the feeding device 10 of the present invention is shown.

[0042] The motor 21 is installed on the fixed block 11 , and the first gear 22 is installed on the output shaft 211 of the motor 21 . The right drive shaft 26 is installed on the fixed block 11 through the right shaft bearing 261 . Similarly, the left drive shaft 27 is installed on the fixed block 11 through the left shaft bearing 271 . Both the right drive shaft 26 and the left drive shaft 27 can rotate on the fixed block 11 . The second gear 23 , the third gear 24 and the right feed roller 31 are respectively fixedly inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com