High-speed optical fiber drawing tower

A drawing tower and optical fiber technology, applied in the field of optical fiber production, can solve the problems of restricting optical fiber production capacity, increasing optical fiber manufacturing cost, and large consumption of helium.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

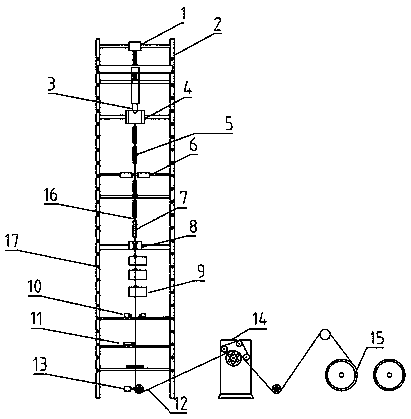

[0017] see figure 1 , a high-speed optical fiber drawing tower, including a tower body frame 2, a plurality of symmetrically arranged screw holes 17 are opened on the tower body frame 2, and high-precision feeding devices are sequentially arranged on the inside of the tower body frame 2 from top to bottom 1. High temperature furnace 4, annealing tube 5, bare fiber diameter detector 6, cooling pipe 7, coating system 8, curing furnace 9, eccentricity detection system 10, twisting device 11 and tension detection device 13; the tower body The skeleton 2 is fixed with screws according to the requirements of different levels. The height of the tower body skeleton 2 is 44m, and the outside of the tower body skeleton 2 is provided with a traction device 14 and a double take-up device 15 arranged side by side; The preform 3 is loaded into the high-precision feeding device 1, and the preform 3 moves downward through the high-precision fine material device and enters the high-temperature...

Embodiment 2

[0022] On the basis of Embodiment 1, the cooling pipe 7 is a normally closed circular cooling pipe 7, the cooling pipe 7 is a multi-section structure, and helium holes are provided on the even-numbered nodes of the cooling pipe 7 for Helium is delivered to the cooling tube 7, and the bottom of the cooling tube 7 is completely sealed with the mold gland, which avoids the breakage caused by foreign matter falling into the mold in the drawing light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com