A lens module grid lighting fixture

A lens module and lighting technology, applied in the field of lighting, can solve the problems of affecting the uniformity of light distribution of lamps, unable to achieve accurate light distribution, increasing the loss of luminous flux, etc., so as to reduce visual discomfort, reduce the loss of luminous flux, Glare reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

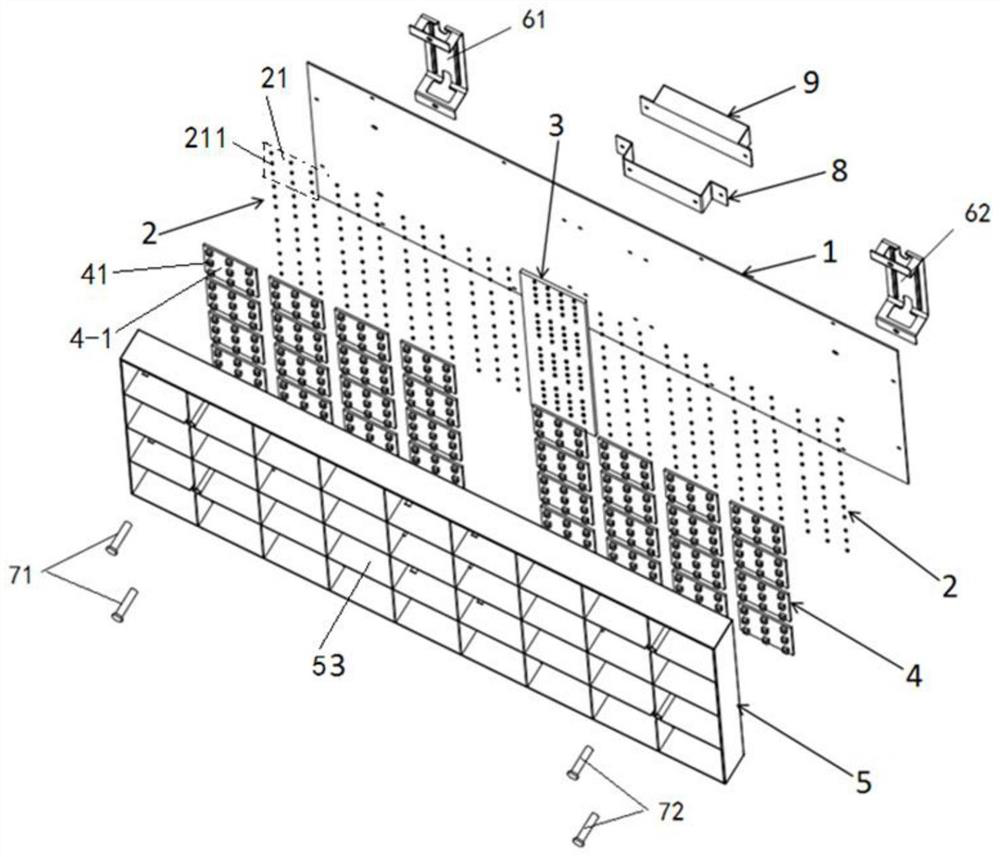

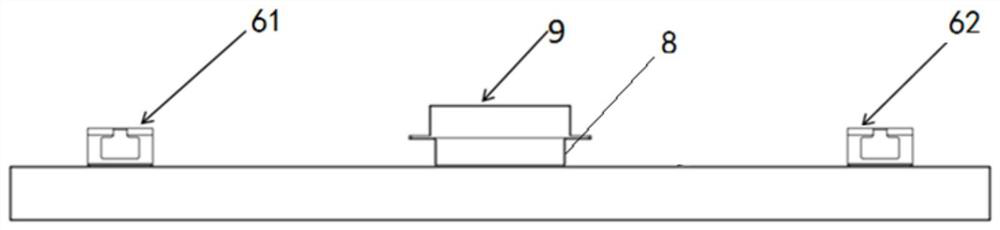

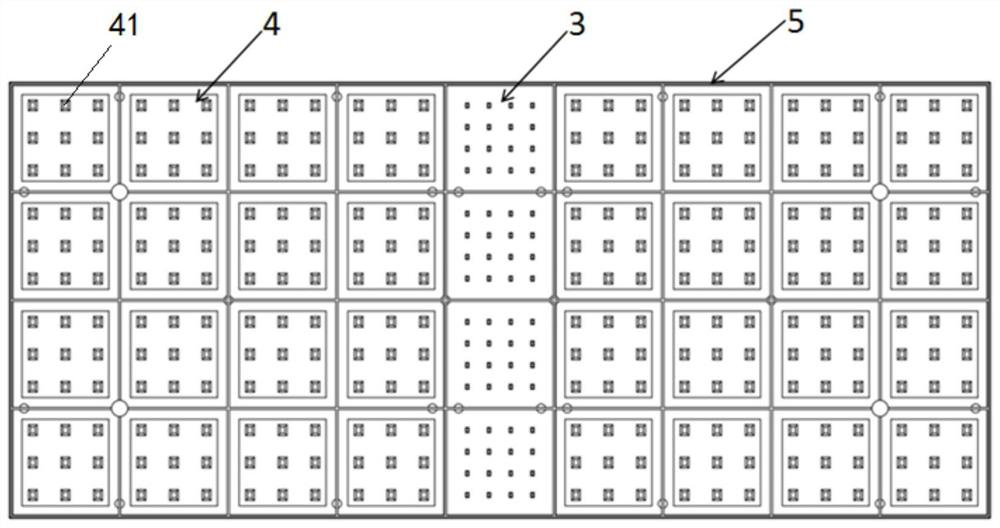

[0034] refer to Figure 1 to Figure 6 As shown, a preferred embodiment of the present invention is an eye protection lighting fixture, including: a rear cover 1 , a lens module 4 , a grille 5 , a hanging arm 61 , a hanging arm 62 , a power supply bracket 8 , and a power supply 9 . Such as figure 1 As shown, the rear cover 1 is a rear lampshade and circuit board; the front surface of the rear cover 1 includes a plurality of light emitting units 21 and a special light emitting area 3 . A plurality of light emitting units 21 constitute the white light emitting area 2; the lens module 4 is installed in front of the back cover 1; the grille 5 is fixedly connected with the back cover 1, and has functions of controlling glare and concentrating light. A pair of screw posts 71 pass through the screw holes 53 of the grille 5 and the screw holes of the rear cover 1 and are fixedly connected with the hanging arm 61, and the other pair of screw posts 72 pass through the screw holes 52 of ...

Embodiment 2

[0038] refer to Figure 7 to Figure 11As shown, the preferred embodiment 2 of the present invention includes: a rear cover 1 , a lens module 4 , a grille 5 , hanging arms 61 , 62 , two power supply brackets 8 , a power supply 9 , buckles 11 , and screw holes 12 . The back cover 1 is a rear lampshade and a circuit board, and the front surface of the back cover 1 includes a plurality of light emitting units 21; each light emitting unit 21 contains a plurality of single LED white light sources and LED special light sources welded and fixed on the front surface of the back cover 1 The lens module 4 includes a plurality of module units 4-1; the grid 5 is formed by vertically crossed grid bars; the grid 53 of the light emitting unit 21, the module unit 4-1 and the grid 5 One-to-one correspondence of positions. The single LED white light source 211 and the LED special light source in each light emitting unit 21 correspond to the position of the lens unit 41 in the module unit 4-1 on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com