Three-ring fire combustor

A burner and ring fire technology, applied in the direction of burner, gas fuel burner, combustion type, etc., can solve the problem of low thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

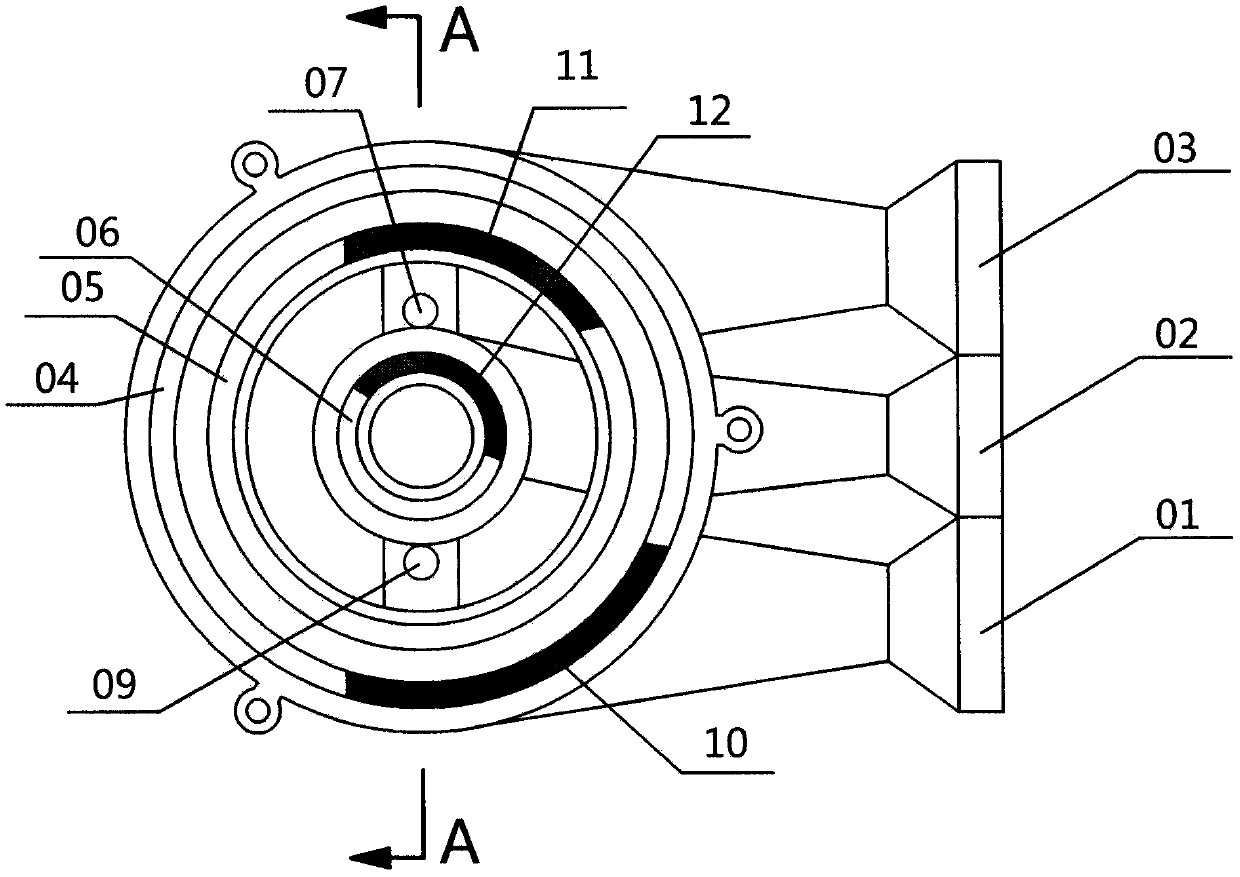

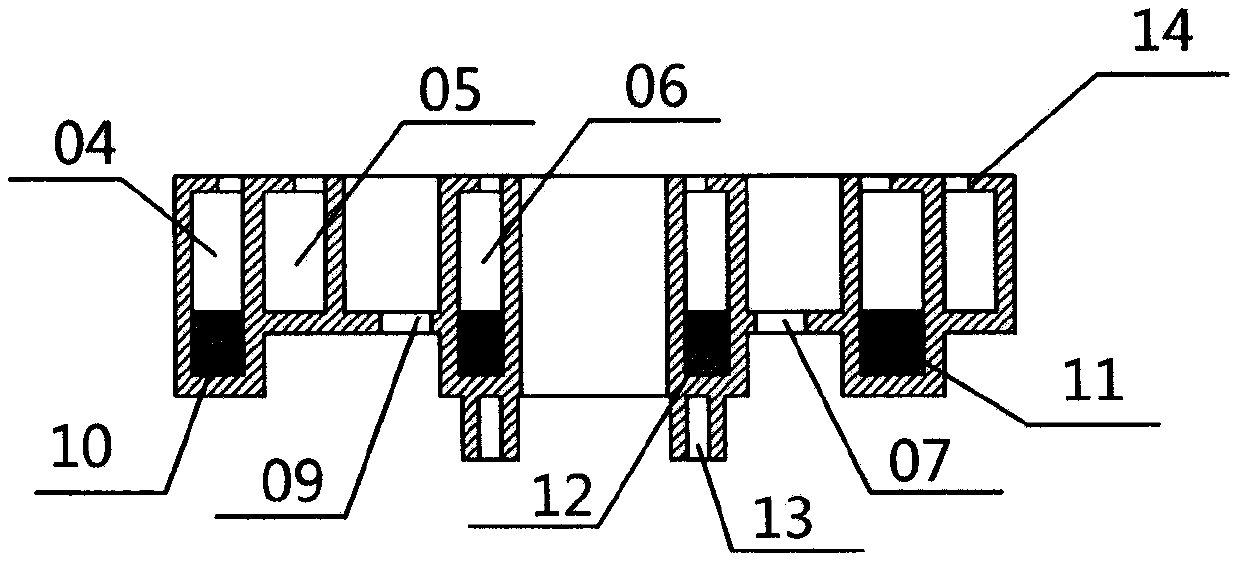

[0038] Example two, in Figure 12 , Figure 13 , Figure 14 , Figure 15 middle:

[0039] Secondary torch (43) circle is set on the auxiliary torch cover (41) of example two; The auxiliary torch flame hole (45) is set on the auxiliary torch (43) top clockwise direction and the outer direction of the flame cover, and the auxiliary torch flame hole (45) center The angle between the line and the horizontal line is greater than 20 degrees; the auxiliary torch flame hole (45) is at least 10 millimeters away from the example two auxiliary fire cover (41);

[0040] Main torch (44) circle is set on the main flare cover (42) of example two; The angle between the line and the horizontal line is greater than 20 degrees; the main torch flame hole (46) is at least 10 millimeters away from the main torch cover (42) of example two;

[0041] Put the auxiliary fire cover (41) of Example 2 on the auxiliary fire air supply groove (04) to form an auxiliary fire burner; put the example 2 main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com