Method for solving problems of moisture absorption and stickiness of fabric with phosphorus flame retardant coating

A coated fabric, phosphorus-based flame-retardant technology, applied in the direction of flame-retardant fibers, textiles and papermaking, improved hand-feeling fibers, etc., can solve the problems of moisture absorption and stickiness of flame-retardant grades, and achieve energy saving, common and cheap raw materials, Improvement effect of moisture absorption and stickiness defect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

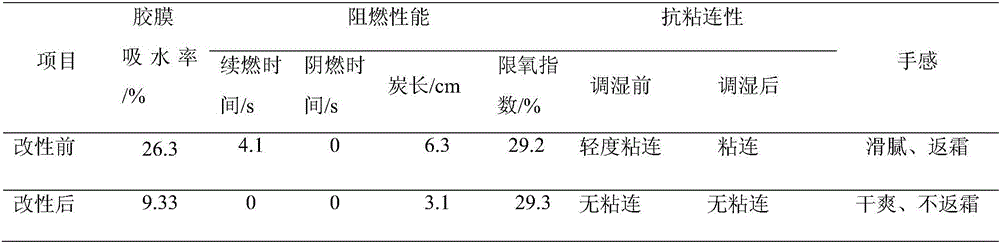

Embodiment 1

[0057] (1) Preparation of silica modified sol

[0058]Add 50mL of absolute ethanol, 0.05mol of methyltrimethoxysilane, and 0.01mol of tetraethyl orthosilicate to the reactor successively, adjust the pH value to 9-10 with ammonia water, and raise the temperature to 50°C; Add 0.04 mol of water dropwise, and continue to stir for 2 hours after the drop of water is completed, so as to obtain a stable, uniform, and transparent silica sol.

[0059] (2) Preparation of phosphorus-silicon synergistic flame retardant

[0060] Add 10% ammonium polyphosphate to the sol prepared above, and stir at high speed for 2 hours until completely and evenly dispersed. Then put the mixture into a constant temperature drying oven at 50°C for 2 hours to make it gel and remove the solvent to obtain a phosphorus-silicon synergistic flame retardant.

[0061] (3) Hydrophobic phosphorus-based flame-retardant coating finishing

[0062] The flame retardant finishing process is: EMU, high-speed rail polyeste...

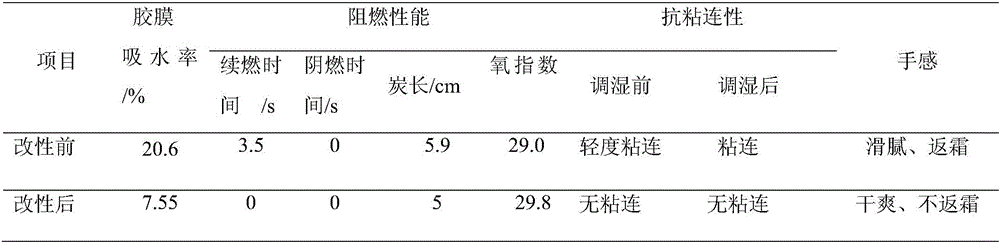

Embodiment 2

[0072] (1) Preparation of silica modified sol

[0073] Add 60mL of absolute ethanol, 0.05mol of ethyltrimethoxysilane and 0.01mol of tetraethylorthosilicate to the reactor successively, adjust the pH value to 9-10 with ammonia water, and raise the temperature to 50°C; Gradually add 0.04 mol of water, and continue to stir for 2 hours after the water drops to obtain a stable, uniform, and transparent silica sol.

[0074] (2) Preparation of phosphorus-silicon synergistic flame retardant

[0075] Add 15% cresyl diphenyl phosphate to the sol prepared above, and stir at high speed for 2 hours until completely and evenly dispersed. Then put the mixture into a constant temperature drying oven at 50°C for 1 hour to make it gel and remove the solvent to obtain a phosphorus-silicon synergistic flame retardant.

[0076] (3) Flame retardant coating finishing of hydrophobized ammonium polyphosphate

[0077] The flame retardant finishing process is: EMU, high-speed rail polyester fleece s...

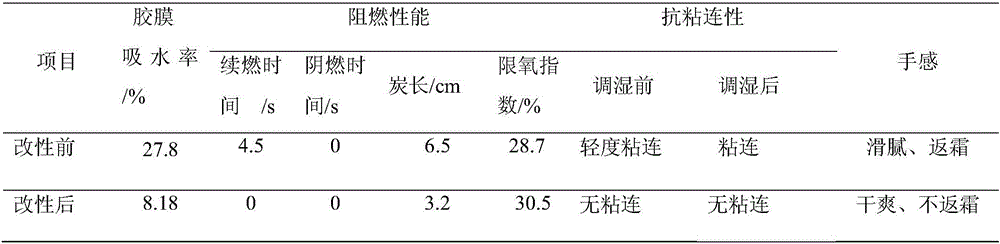

Embodiment 3

[0086] (1) Preparation of silica modified sol

[0087] Add 50mL of absolute ethanol, 0.05mol of octadecyltrimethylsilane and 0.01mol of tetraethyl orthosilicate to the reactor successively, adjust the pH value to 9-10 with ammonia water, and raise the temperature to 50°C; Gradually drop 0.04mol of water into the solution, and continue to stir for 2 hours after the water drops, to obtain a stable, uniform and transparent silica sol.

[0088] (2) Preparation of phosphorus-silicon synergistic flame retardant

[0089] Add 10% triisopropylphenyl phosphate to the sol prepared above, and stir at high speed for 2 hours until completely and evenly dispersed. Then put the mixture into a constant temperature drying oven at 50° C. for 1.5 hours to make it gel and remove the solvent to obtain a phosphorus-silicon synergistic flame retardant.

[0090] (3) Flame retardant coating finishing of hydrophobized ammonium polyphosphate

[0091] The flame retardant finishing process is: EMU, high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com