Refractory brick

A technology of refractory bricks and brick bodies, which is applied in the field of refractory bricks, can solve the problems of refractory bricks easy to fall off, and achieve the effect of simple structure, reduced fall-off, and strengthened light connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

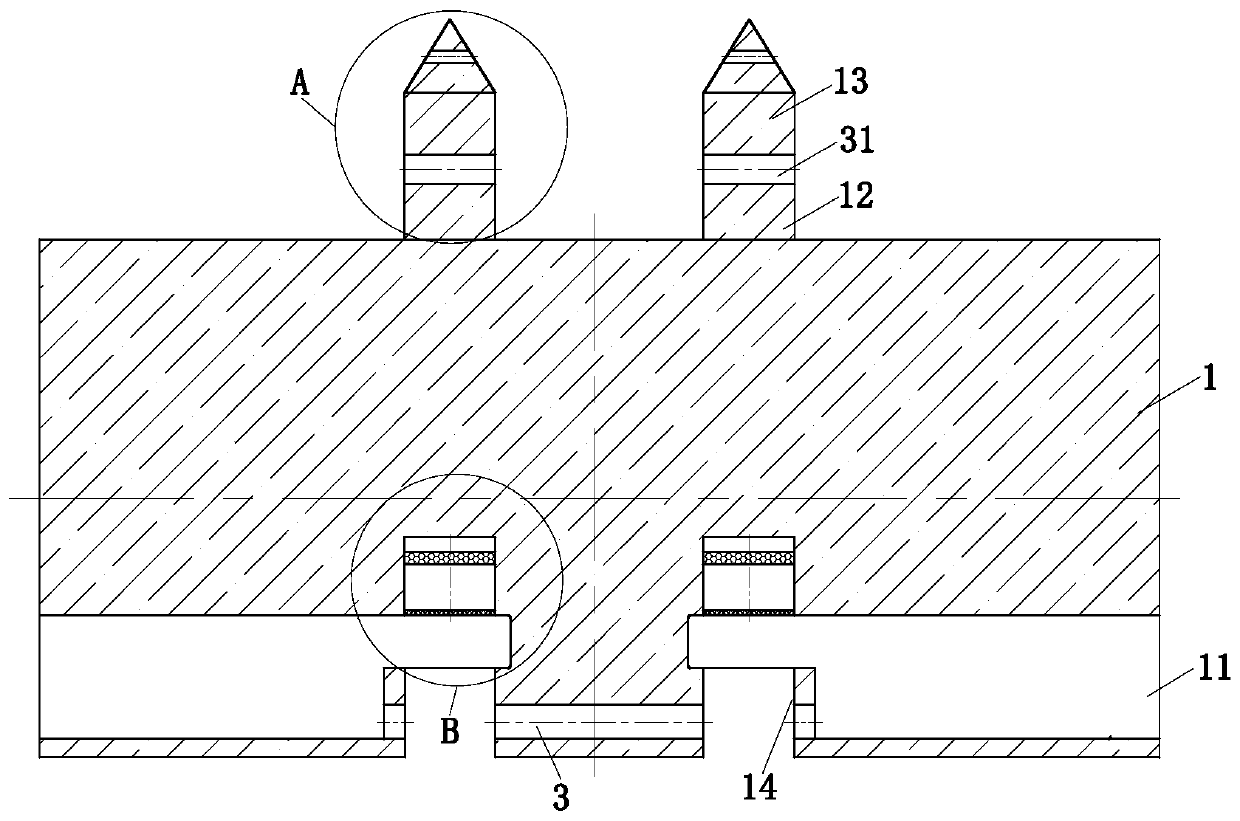

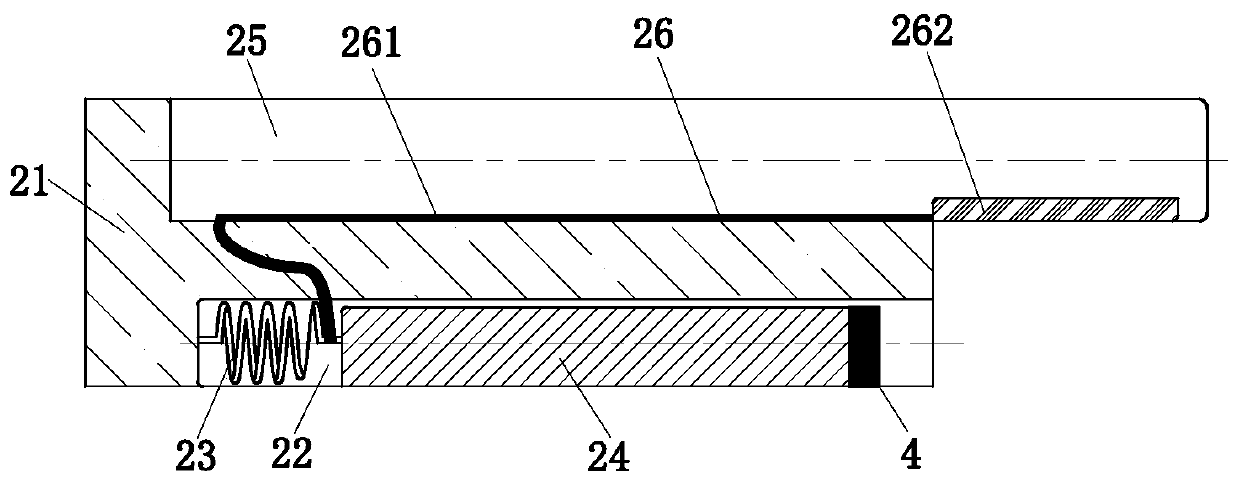

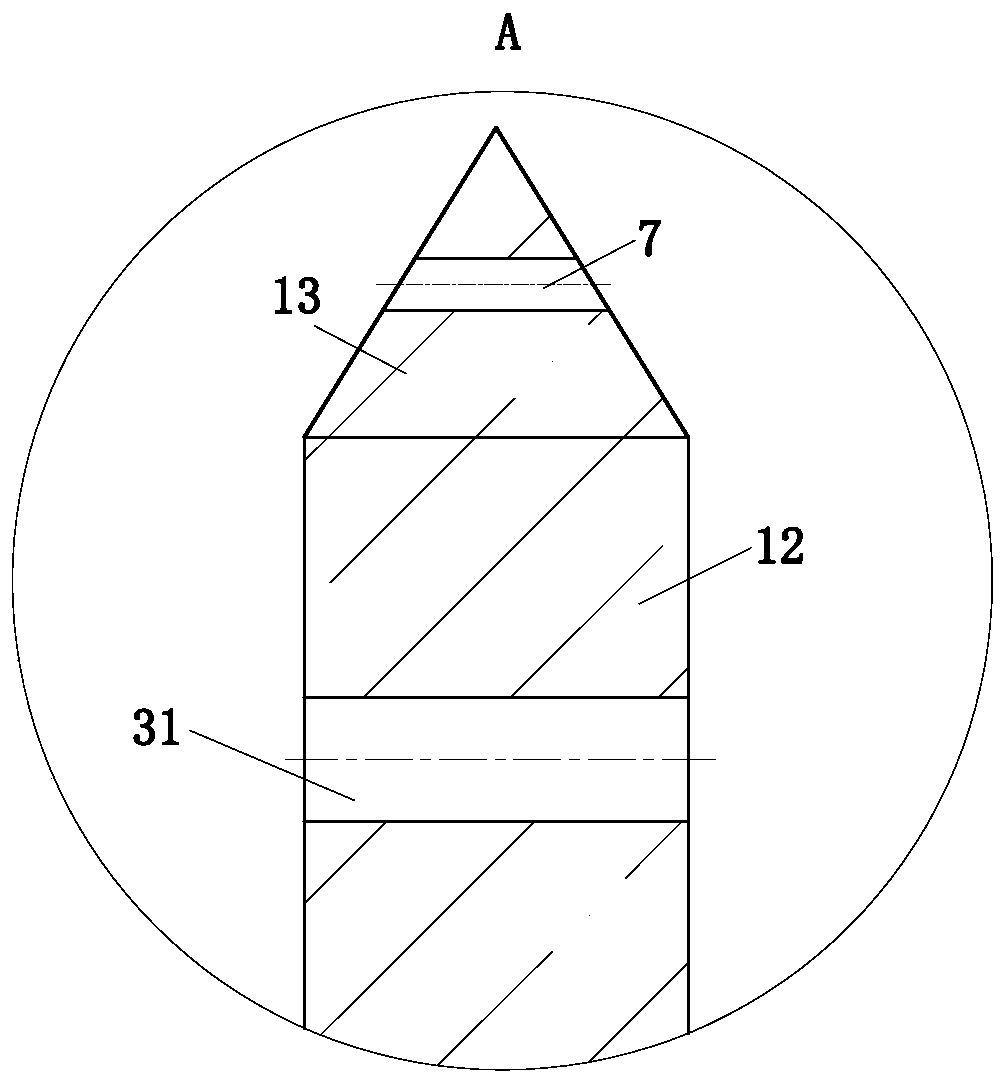

[0023] Such as Figure 1 to Figure 6 As shown, a refractory brick according to the present invention includes a brick body 1 and an engaging unit 2; the inside of the brick body 1 is provided with a prefabricated hole 11 for placing the engaging unit 2; the top of the brick body 1 There are clamping columns 12 arranged symmetrically on the basis of the vertical center line of the brick body 1, and the end of the clamping column 12 far away from the brick body 1 is provided with an arrow 13 whose section shape is conical; the bottom of the brick body 1 is provided with a place card The notch 14 of the column 12; the brick body 1 and the card column 12, the card column 12 and the arrow 13 are uniformly fired and molded; a cavity 15 is provided above...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap