Nh-fuse load break switch

A circuit breaker and fuse technology, which is applied in the field of NH fuse load circuit breakers, can solve the problems of large housing and a large amount of installation space, and achieve the effect of reducing volume, space or structure space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

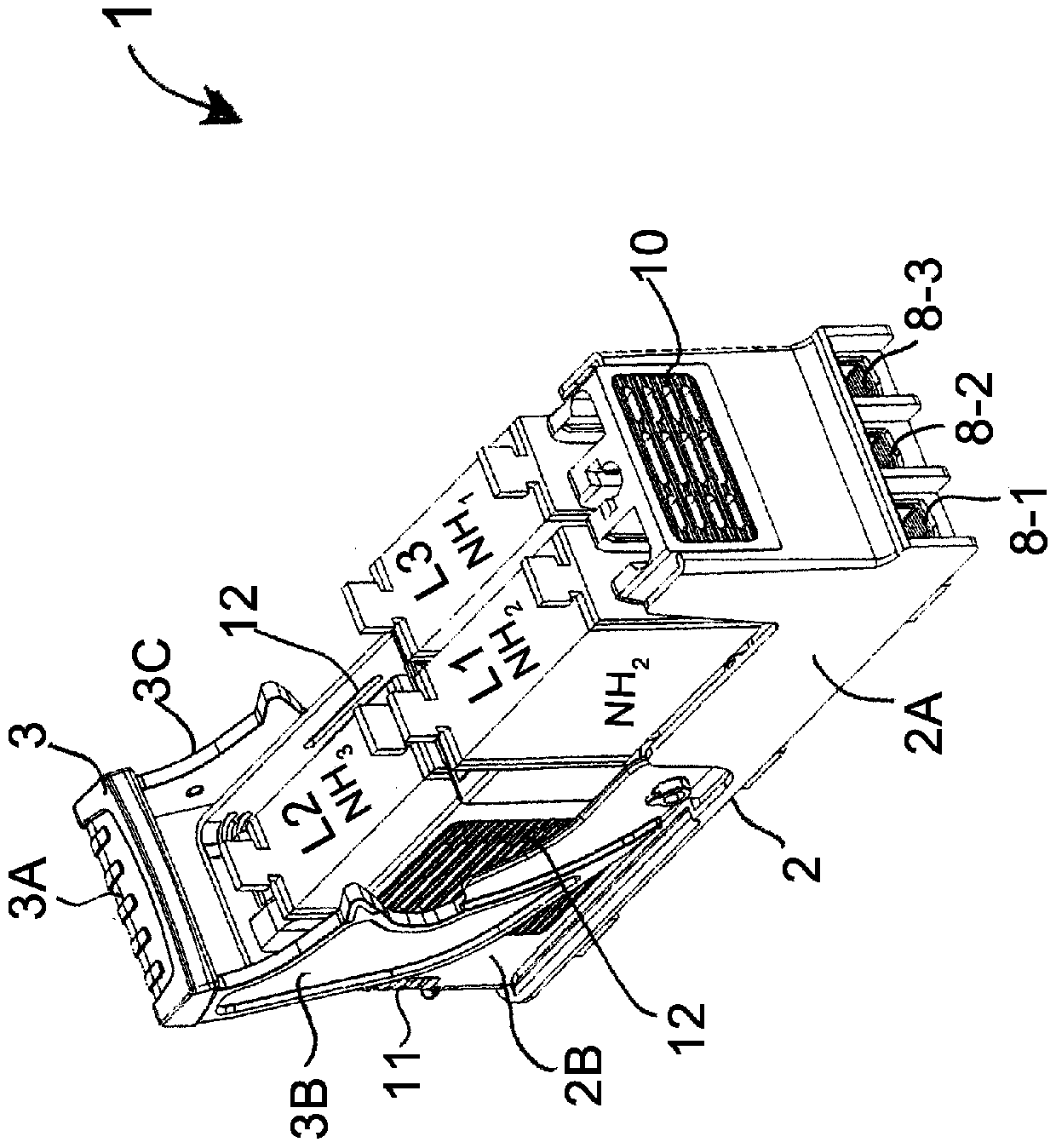

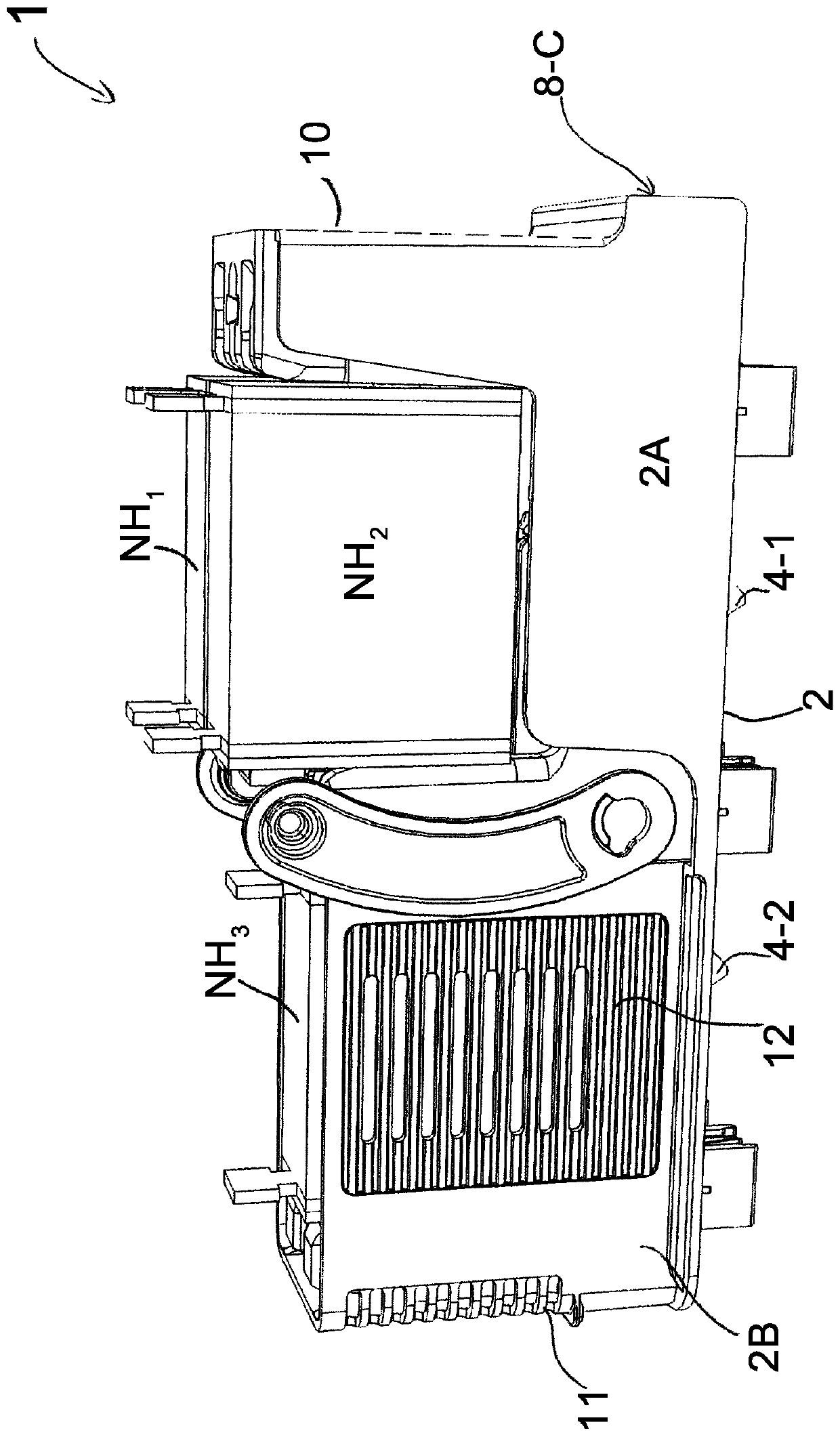

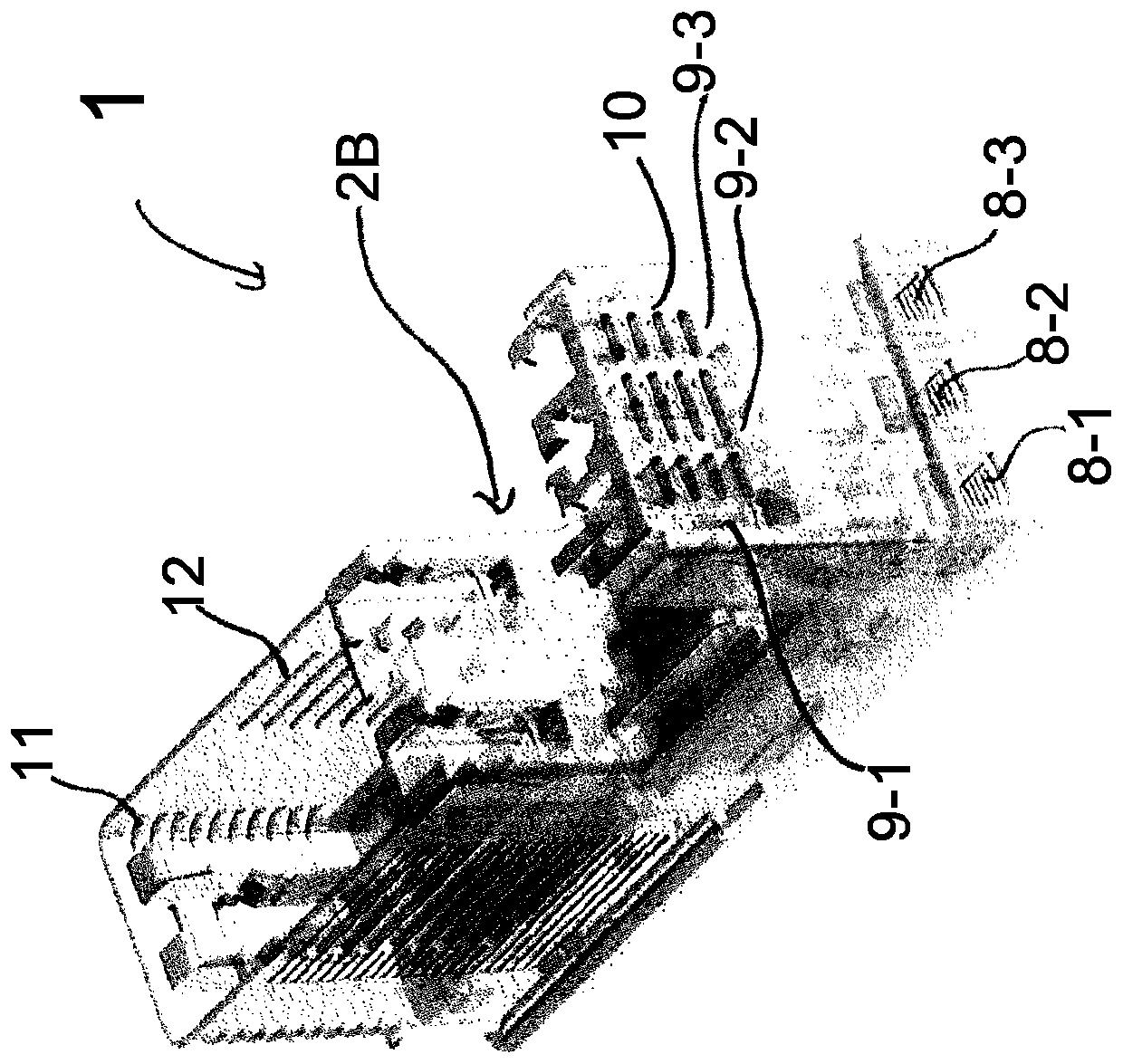

[0039] figure 1 According to the invention an embodiment of an NH-fuse load-break switch 1 according to the invention is shown. NH fuse load break switch or load break switch 1 set for multiple NH fuses. The load disconnect switch 1 has a housing 2 . The housing 2 is preferably composed of two parts and comprises a lower part 2A and a contact holder 2B. In a preferred embodiment, the contact holder 2B consists of a thermally conductive plastic. The housing 2 of the load break switch 1 is used to accommodate a plurality of NH fuses. For this purpose, the preferred setting is as image 3 The thermally conductive contact carrier 2B is shown. In the illustrated embodiment, the housing 2 of the load break switch 1 contains three NH fuses NH1 , NH2 , NH3 for three different current phases L1 , L2 , L3 . The NH fuse load break switch 1 can be assembled to a current carrying rail, especially a bus bar. In the assembled state, the housing 2 of the load-break switch 1 is preferab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com