nh fuse load break switch

A circuit breaker and fuse technology, which is applied in the field of NH fuse load circuit breaker, can solve the problems of large installation space and large casing, and achieve the effect of reducing space or structure space, reducing volume and more usable space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

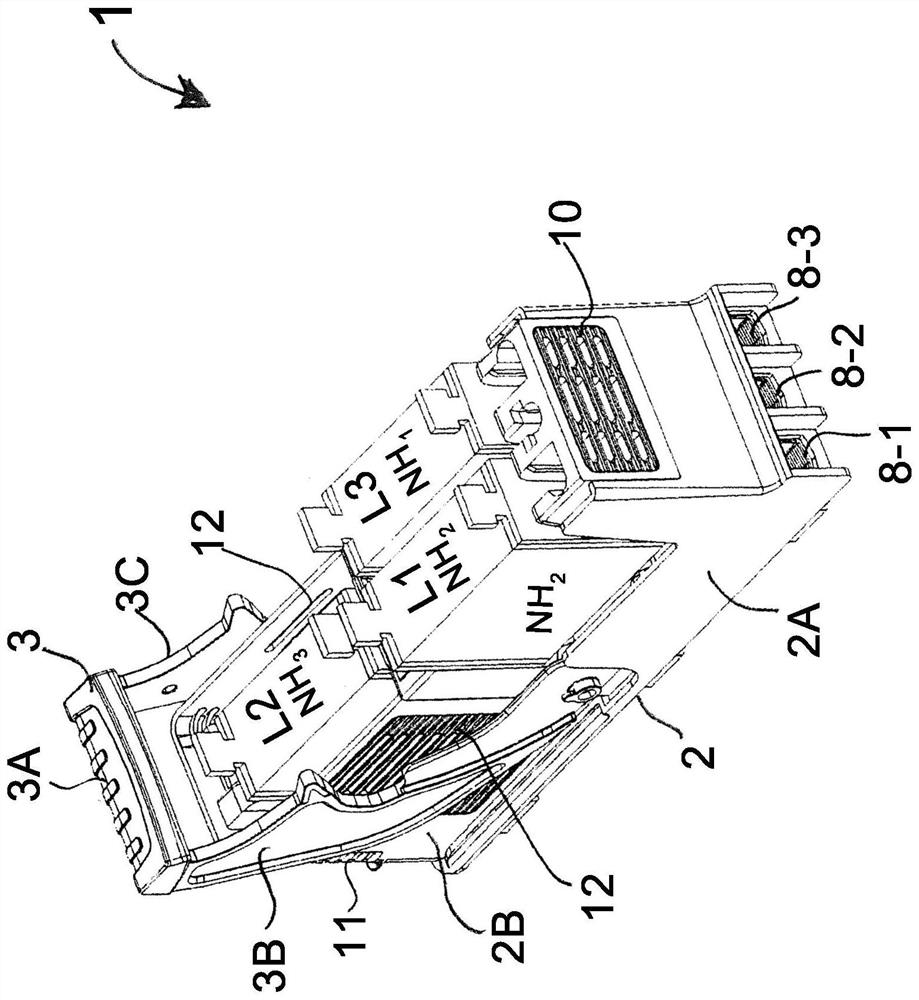

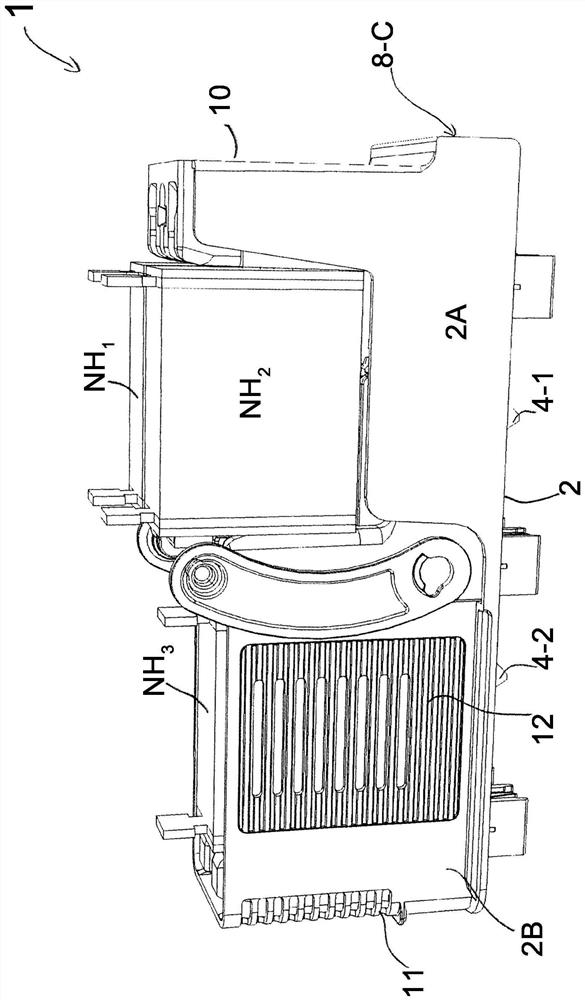

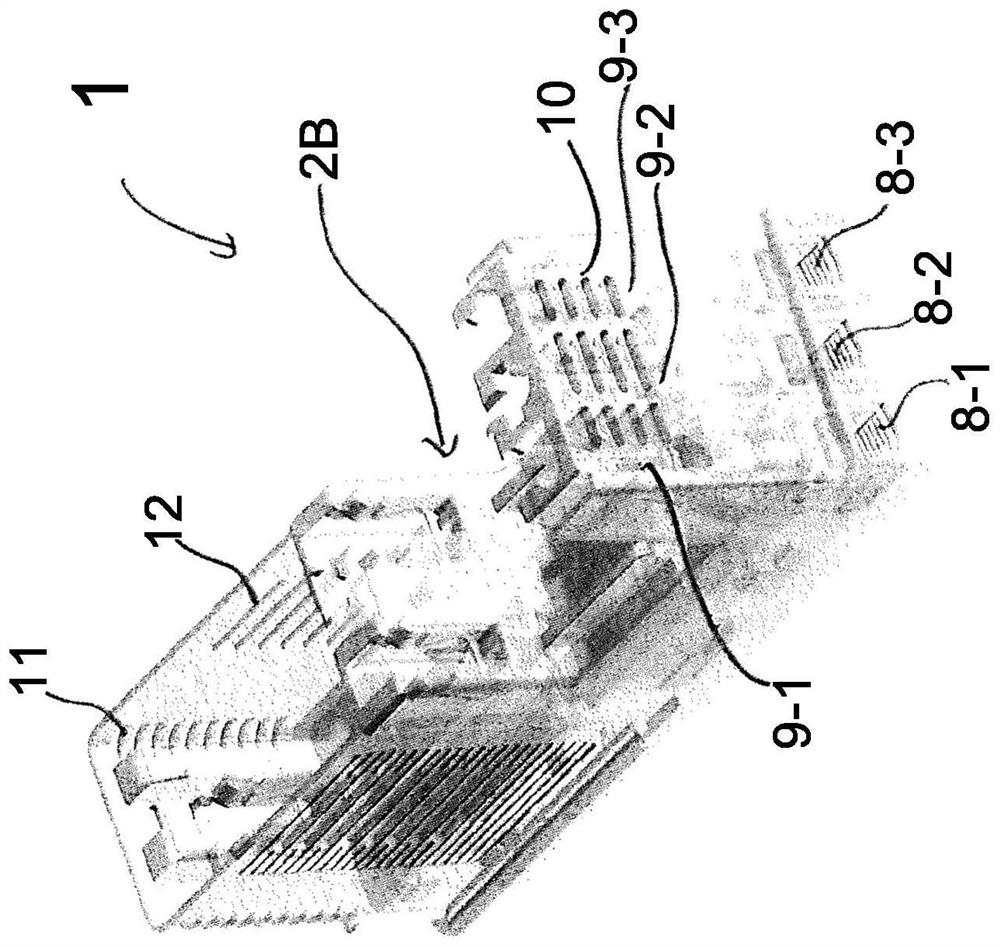

[0039]figure 1 An embodiment of the NH fuse load circuit switch 1 according to the present invention is shown in accordance with the present invention. The NH fuse load circuit switch or load circuit switch 1 is provided for a plurality of NH fuses. The load circuit switch 1 has a housing 2. The housing 2 is preferably composed of two portions and includes lower portions 2a and contact brackets 2b. In a preferred embodiment, the contact bracket 2b comprises a thermally conductive plastic. The housing 2 of the load circuit switch 1 is used to accommodate a plurality of NH fuses. To this end, it is preferred to setimage 3 The illustrated contact bracket 2b is shown. In the illustrated embodiment, the housing 2 of the load circuit switch 1 comprises three NH fuses NH1, NH2, NH3 for three different current phase L1, L2, L3. The NH fuse load circuit switch 1 can be assembled to the carrier rail, in particular on the bus bar. In the assembly state, the housing 2 of the load circuit switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com