Light-emitting diode device and light-emitting device

A technology of light-emitting diodes and light-emitting devices, which is applied to electric solid devices, semiconductor devices, electrical components, etc., can solve the problems such as the development limit of external quantum efficiency of phosphors, poor stability of white LED devices, and the stability to be solved, so as to prevent water pollution. The effect of entering the fluorescent glue layer, strong light effect and stability, reducing the probability of moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

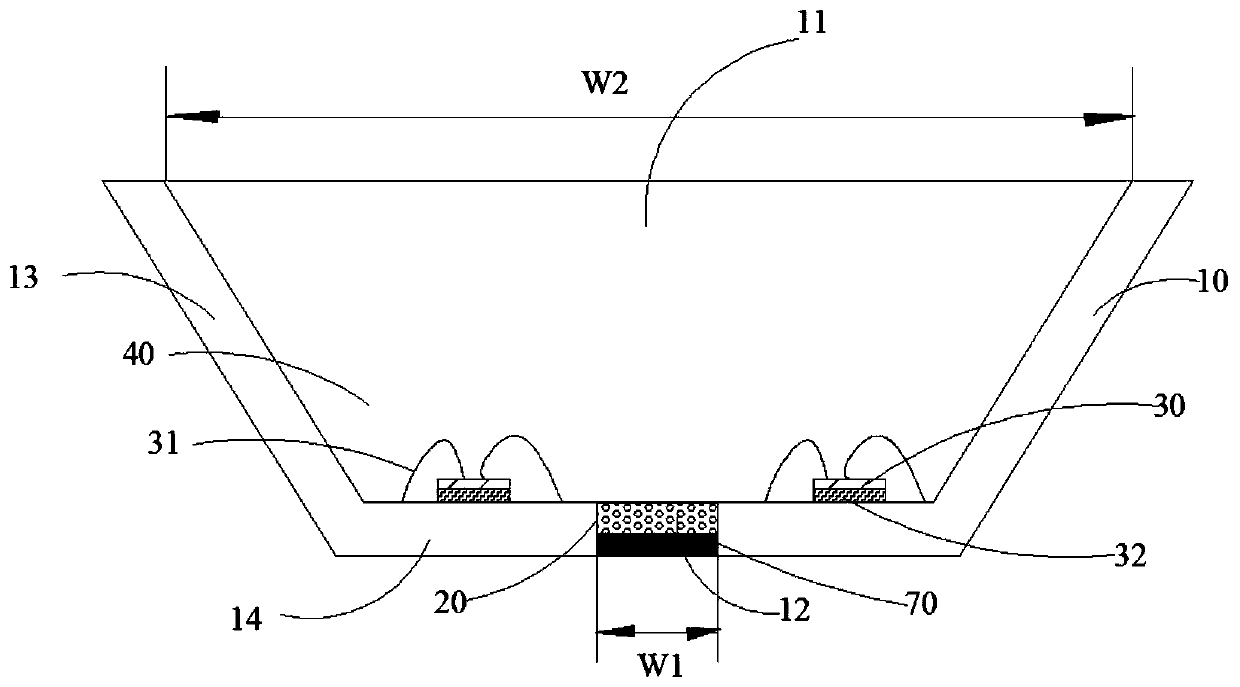

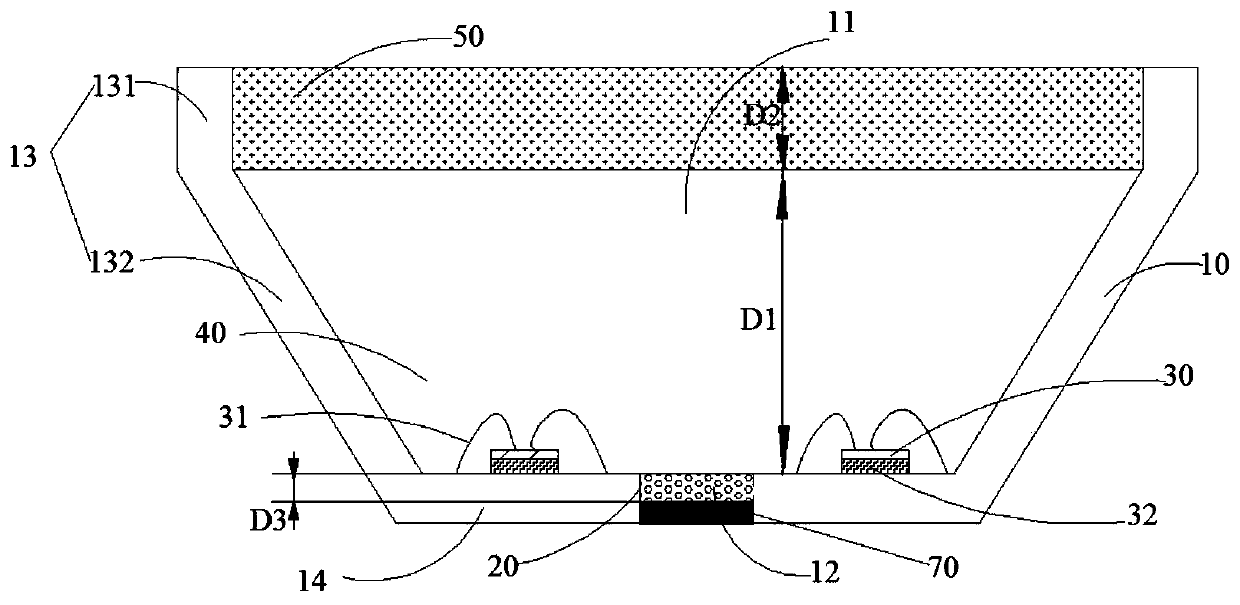

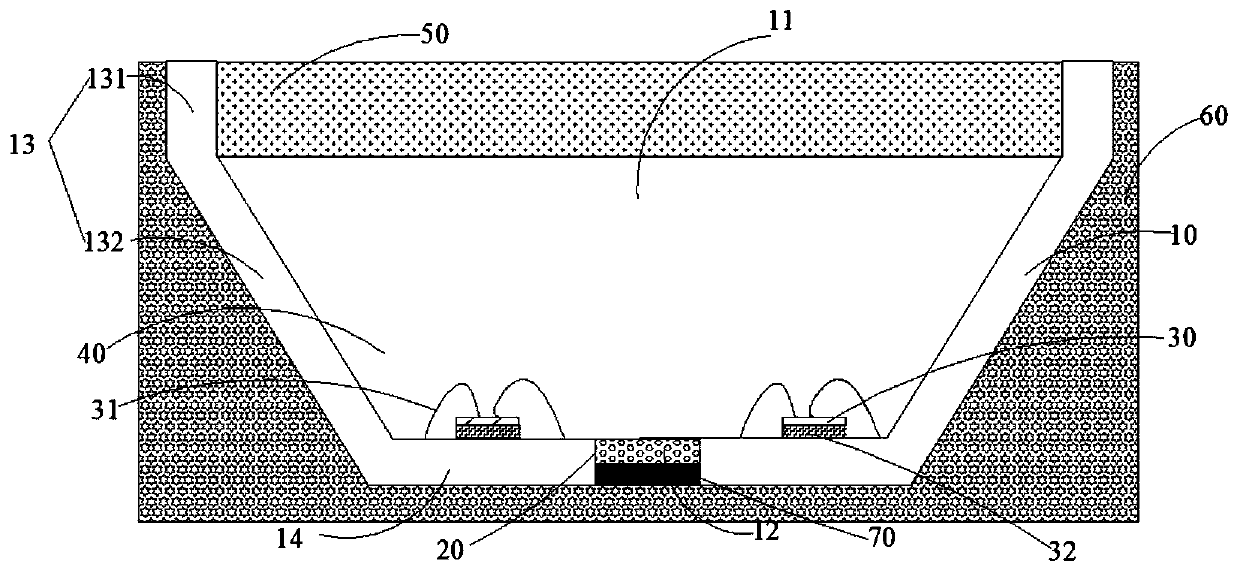

[0086] The structure of light-emitting diode devices such as figure 2 As shown, it includes a bracket 10 provided with a groove 11, a waterproof layer 20, a water-absorbing layer 70, a fluorescent glue layer 40, an anti-vulcanization layer 50 and two blue LED chips 30 arranged at intervals, and the bracket 10 includes a bottom wall 14 and side walls 13. The side wall 13 has a vertical section 131 and an inclined section 132, the angle between the vertical section 131 and the inclined section 132 is 120°, the thickness D2 of the anti-vulcanization layer 50 is the same as the height of the vertical section 131, and the fluorescent glue layer 40 The thickness D1 is the same as the height of the inclined section 132, the bottom wall is provided with a through hole 12, and the through hole 12 is provided with a waterproof layer formed by methyl silicone resin, wherein the width of the waterproof layer (that is, the width of the through hole) is the same as that of the fluorescent l...

Embodiment 2

[0088] The structure of the light-emitting diode device is the same as that of Embodiment 1, except that the weight ratio of the nitride red phosphor powder and the fluoride red phosphor powder is 1:3.

Embodiment 3

[0090] The structure of the light-emitting diode device is the same as that of Example 1, except that the weight ratio of the nitride red phosphor powder and the fluoride red phosphor powder is 1:4, and its light-color performance is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com