Front straw smashing recycling device

A straw crushing and recovery device technology, which is applied in the direction of harvesters, crop processors, cutters, etc., can solve the problem of dirty straw picking and achieve the effect of improving the straw picking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

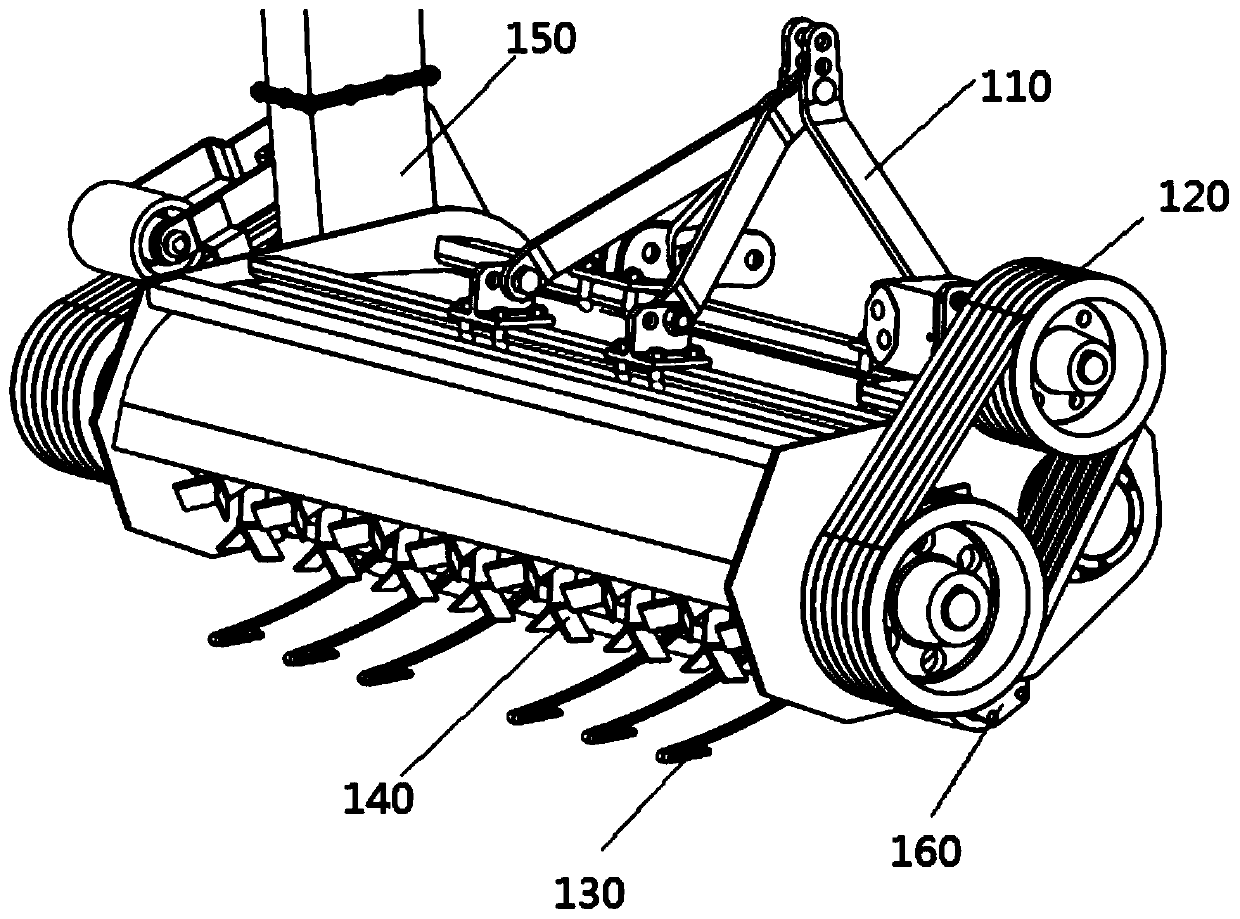

[0061] Such as figure 1 As shown, a front-mounted straw crushing and recycling device of the present invention includes a crushing and recycling machine housing 110 , a power transmission device 120 , profiling spring teeth 130 , a picking and chopping device 140 , a feeding device 150 , and a profiling device 160 .

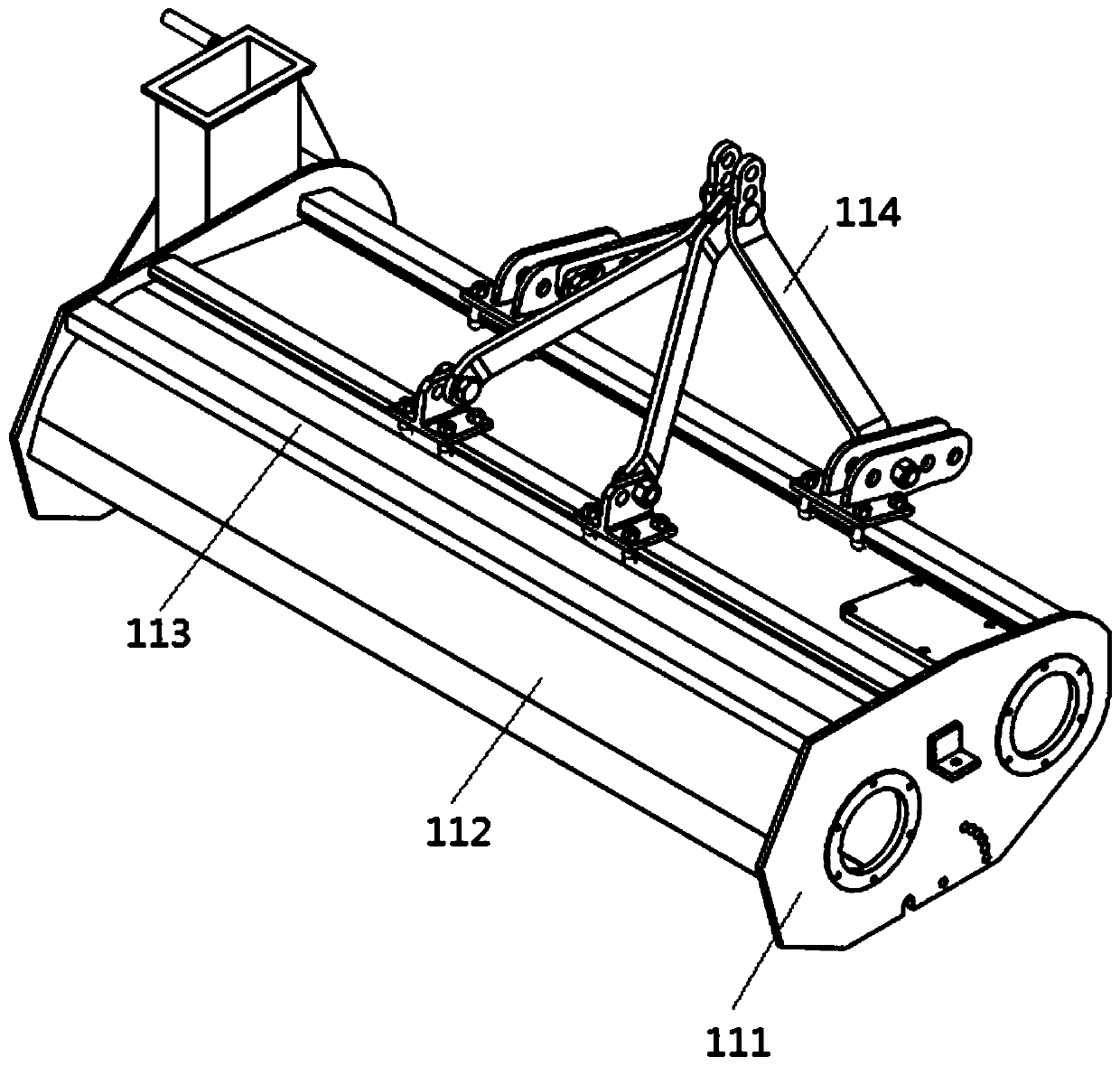

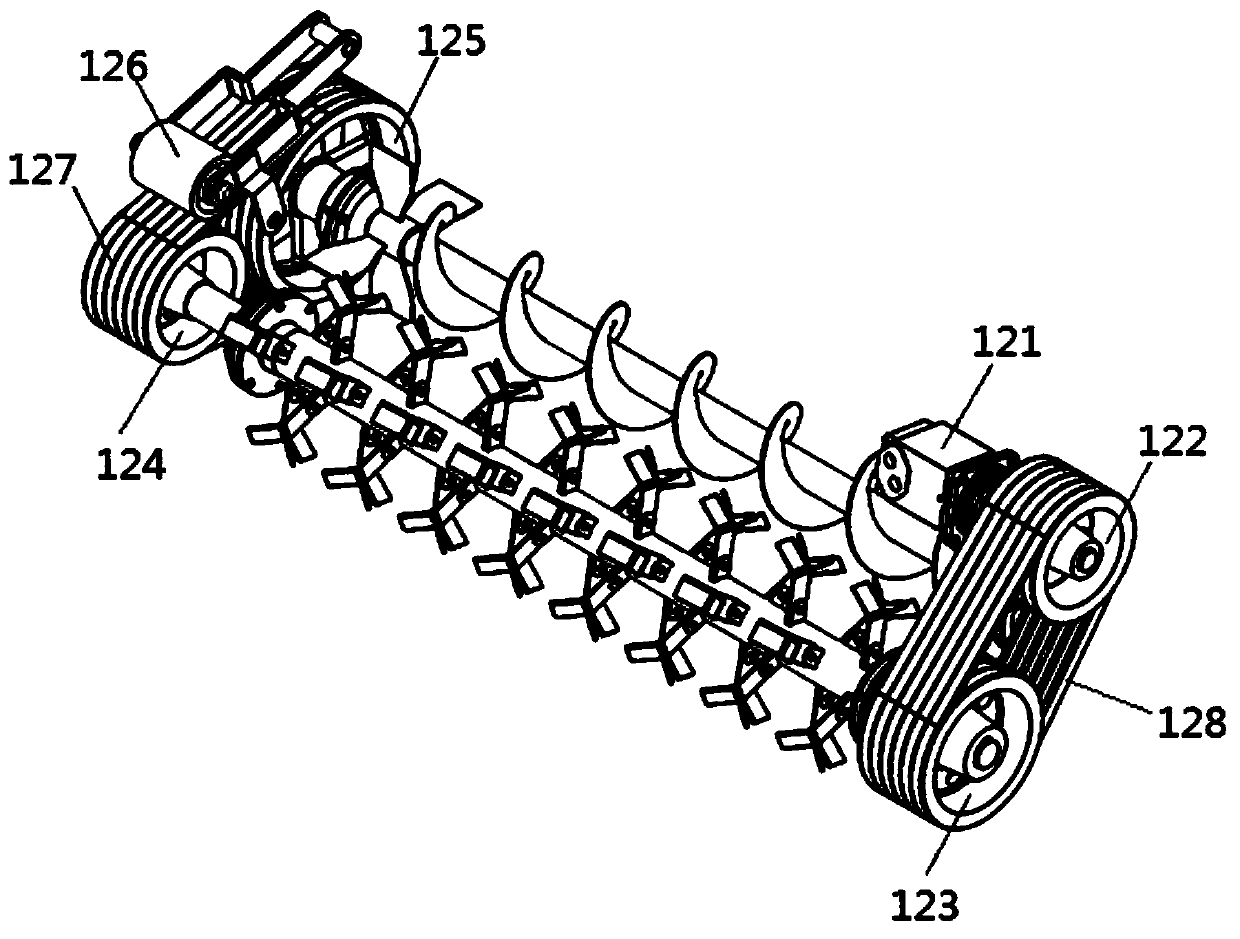

[0062] Such as Figure 2-8 As shown, the crushing recovery housing 110 includes a pair of side plates 111 and a beam 113, the side plates 111 are arranged oppositely at intervals, and the two ends of the beam 113 are respectively fixed on the side plates 111; the blade shaft 141 is rotatably Supported between the side plates 111; a plurality of flailing knives 143 are uniformly arranged on the outer circumferential surface of the flailing knife shaft 141; fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com