Production method of candy-color coated wheel

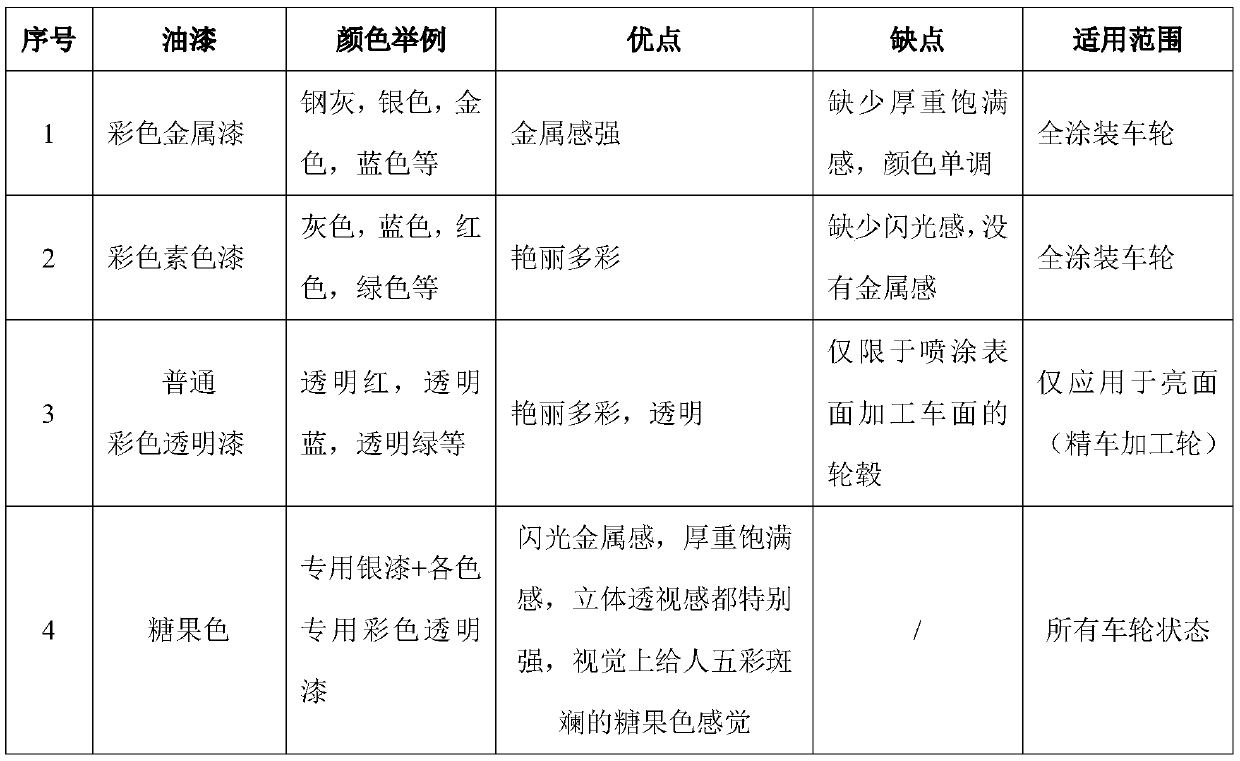

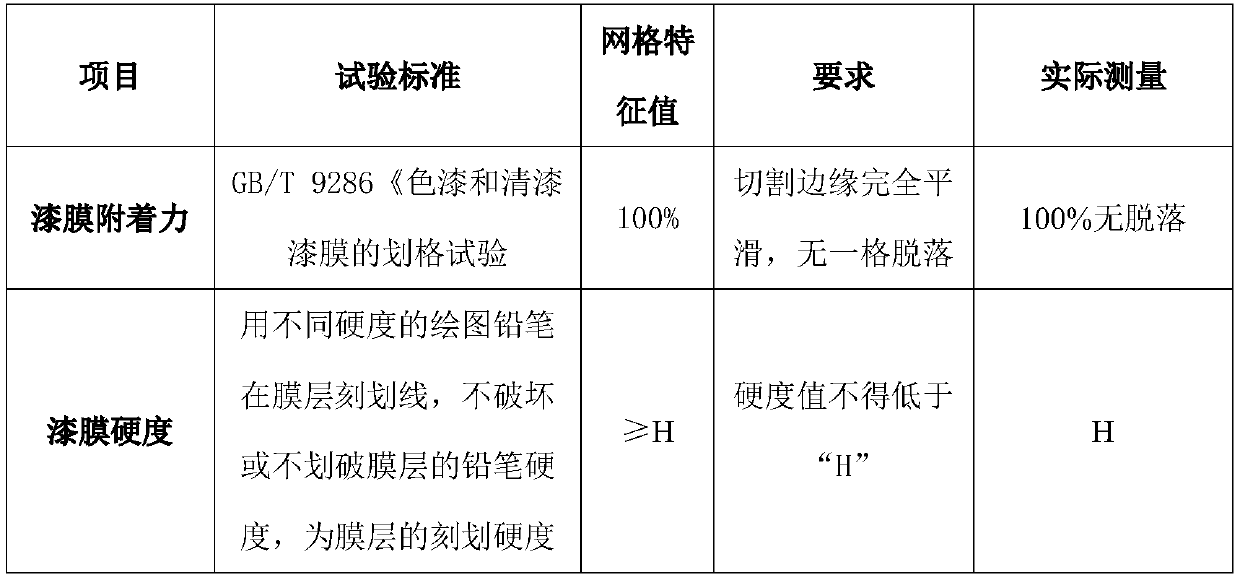

A production method and wheel technology, which are applied to the device, coating, special surface and other directions of coating liquid on the surface, can solve the problems of monotonous color, no metallic feeling, lack of thick and full feeling, etc. Effect of Mounting Adhesion and Hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of production method of candy color coating wheel (product model DW1177), comprises the steps:

[0030] 1. The wheel is sprayed with primer, and the film thickness is 16 μm;

[0031] 2. Primer leveling, the process is temperature 80 ℃, time 9min;

[0032] 3. Spray silver metallic paint with a film thickness of 19 μm and level it. The leveling process is at a temperature of 80°C and a time of 8 minutes;

[0033] 4. According to the color requirements, spray the colored transparent paint with a film thickness of 25 μm and level it. The leveling process is at a temperature of 10°C and a time of 8 minutes;

[0034] 5. Glue and cure the paint on the surface of the wheel. The curing temperature is 190°C and the duration is 20 minutes.

Embodiment 2

[0036] A kind of production method of candy color coating wheel (product model DW1180), comprises the steps:

[0037] 1. The film thickness of the wheel spray primer is 20 μm, which can completely cover the surface defects of the wheel and ensure the adhesion and hardness of the coating;

[0038] 2. Primer leveling, the process is temperature 120 ℃, time 11min;

[0039] 3. Spray silver metallic paint with a film thickness of 23μm and level it. The leveling process is at a temperature of 120°C and a time of 8 minutes;

[0040] 4. According to the color requirements, spray the colored transparent paint with a film thickness of 30μm and level it. The leveling process is at a temperature of 20°C and a time of 10 minutes;

[0041] 5. Glue and cure the paint on the surface of the wheel. The curing temperature is 190°C and the duration is 15 minutes.

Embodiment 3

[0043] A production method of a candy-colored painted wheel (product model DW1575), comprising the steps of:

[0044] 1. The film thickness of the wheel spray primer is 19 μm, which can completely cover the surface defects of the wheel and ensure the adhesion and hardness of the coating;

[0045] 2. Primer leveling, the process is temperature 135 ℃, time 11min;

[0046] 3. Spray silver metallic paint with a film thickness of 20μm and level it. The leveling process is at a temperature of 135°C and a time of 9 minutes;

[0047] 4. According to the color requirements, spray the colored transparent paint with a film thickness of 28 μm and level it. The leveling process is at a temperature of 20°C and a time of 10 minutes;

[0048] 5. Glue and cure the paint on the surface of the wheel. The curing temperature is 190°C and the duration is 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com