A waterproof and wrinkle-resistant polyurethane foam breast cup and its preparation process

A preparation process, polyurethane technology, which is applied in the field of bras and underwear, can solve the problems of uneven thickness of polyurethane foam breast cups, water infiltration, and low water resistance, and achieve the best physical and mechanical strength and weather resistance, uniform and dense cells , The effect of shortening the foaming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

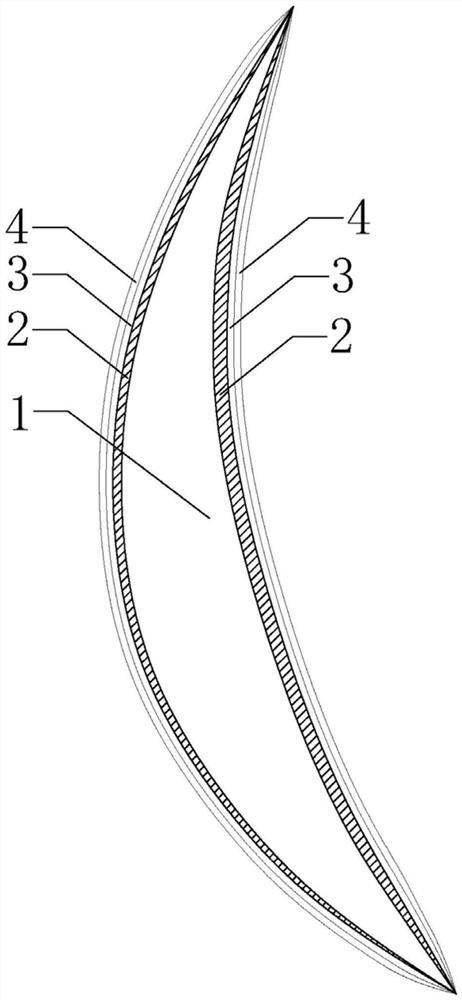

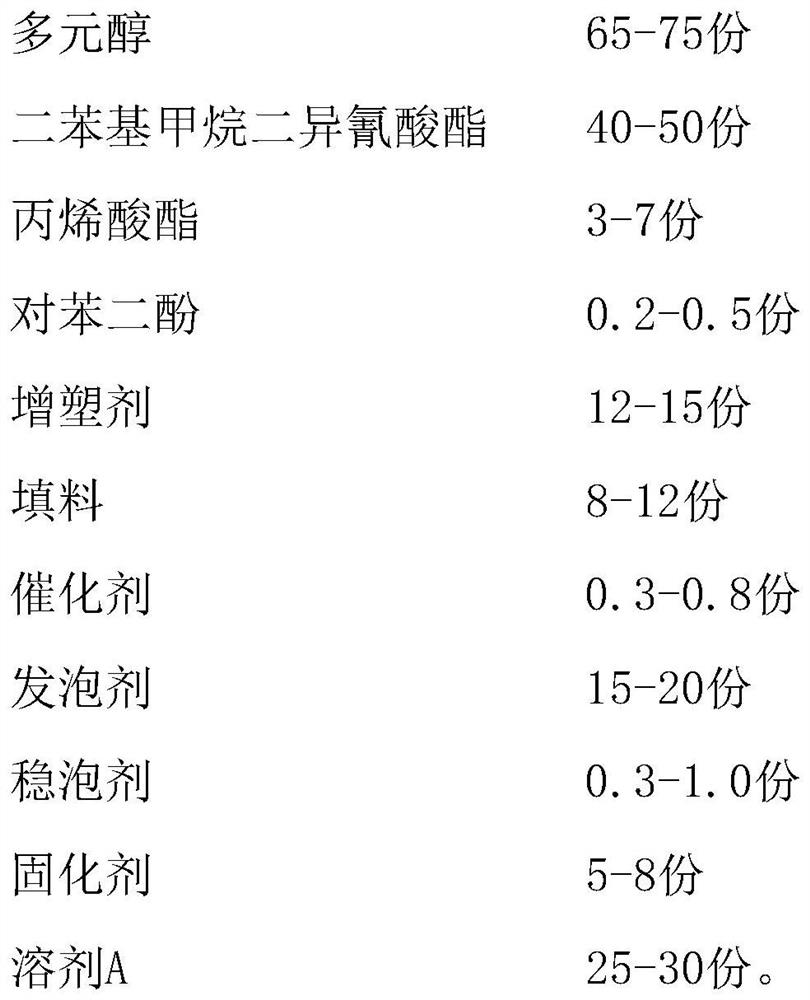

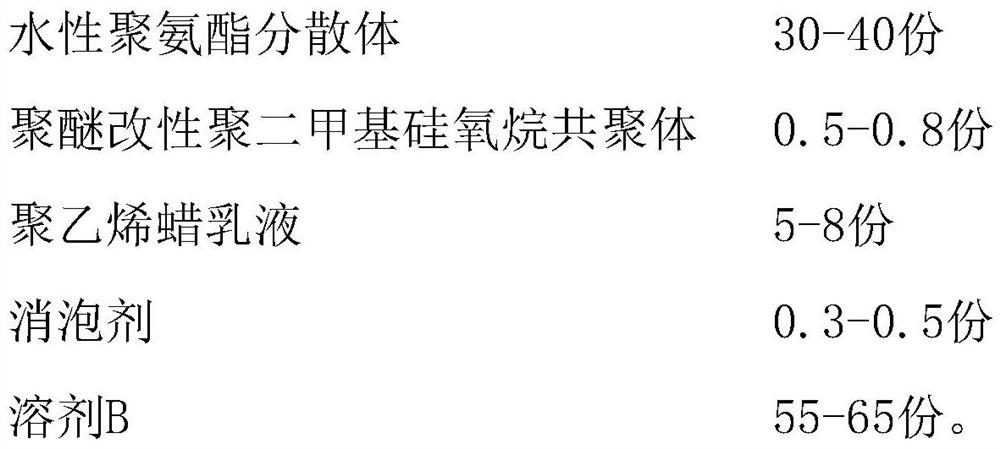

[0045] See figure 1 , a waterproof and wrinkle-resistant polyurethane foam breast cup, the polyurethane foam breast cup comprises a foam breast cup core layer 1, a waterproof layer 2, a water-based topcoat layer 3 and a water-based mold release paint layer 4 arranged sequentially from the inside to the outside , that is, the surface of the foamed breast cup core layer 1 is coated with a waterproof layer 2, a water-based topcoat layer 3 and a water-based release paint layer 4 in sequence; the foamed breast cup core layer 1 and the waterproof layer 2 are all composed of Composite PU material foaming is made, and described composite PU material comprises the raw material of following weight portion:

[0046]

[0047] The polyol is polyether diol.

[0048] The polyether glycol is polyoxyethylene glycol.

[0049] The acrylate is 2-hydroxyethyl acrylate.

[0050] The plasticizer is dioctyl phthalate; the filler is fumed silica.

[0051] The catalyst is stannous octoate; the f...

Embodiment 2

[0066] See figure 1, a waterproof and wrinkle-resistant polyurethane foam breast cup, the polyurethane foam breast cup comprises a foam breast cup core layer 1, a waterproof layer 2, a water-based topcoat layer 3 and a water-based mold release paint layer 4 arranged sequentially from the inside to the outside , the foamed breast cup core layer 1 and the waterproof layer 2 are made of composite PU material foam molding, the composite PU material includes the following raw materials by weight:

[0067]

[0068] The polyol is polyether triol.

[0069] The polyether triol is polyoxypropylene triol.

[0070] The acrylate is hydroxypropyl methacrylate.

[0071] The plasticizer is dioctyl azelate; the filler is titanium dioxide.

[0072] The catalyst is dibutyltin dilaurate; the blowing agent is a mixture of sodium bicarbonate and 1-chloro-3,3,3-trifluoropropene in a weight ratio of 0.8:2;

[0073] The foam stabilizer is polysiloxane-oxyalkylene block copolymer.

[0074] Each...

Embodiment 3

[0087] See figure 1 , a waterproof and wrinkle-resistant polyurethane foam breast cup, the polyurethane foam breast cup comprises a foam breast cup core layer 1, a waterproof layer 2, a water-based topcoat layer 3 and a water-based mold release paint layer 4 arranged sequentially from the inside to the outside , the foamed breast cup core layer 1 and the waterproof layer 2 are made of composite PU material foam molding, the composite PU material includes the following raw materials by weight:

[0088]

[0089] The polyol is a mixture composed of polyether diol and polyether triol in a weight ratio of 1:1.

[0090] The polyether diol is polytetrahydrofuran diol.

[0091] The polyether diol is polyoxyethylene triol.

[0092] The acrylate is 2-hydroxyethyl acrylate.

[0093] The plasticizer is phenyl alkylsulfonate; the filler is carbon black.

[0094] The catalyst is dibutyltin diacetate; the blowing agent is a mixture of sodium bicarbonate and 1-chloro-3,3,3-trifluoropro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com