Sand mold casting production line

A sand casting, production line technology, applied in foundry, casting equipment, manufacturing tools, etc., to deal with sudden increase or decrease, convenient increase and decrease, and clear layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

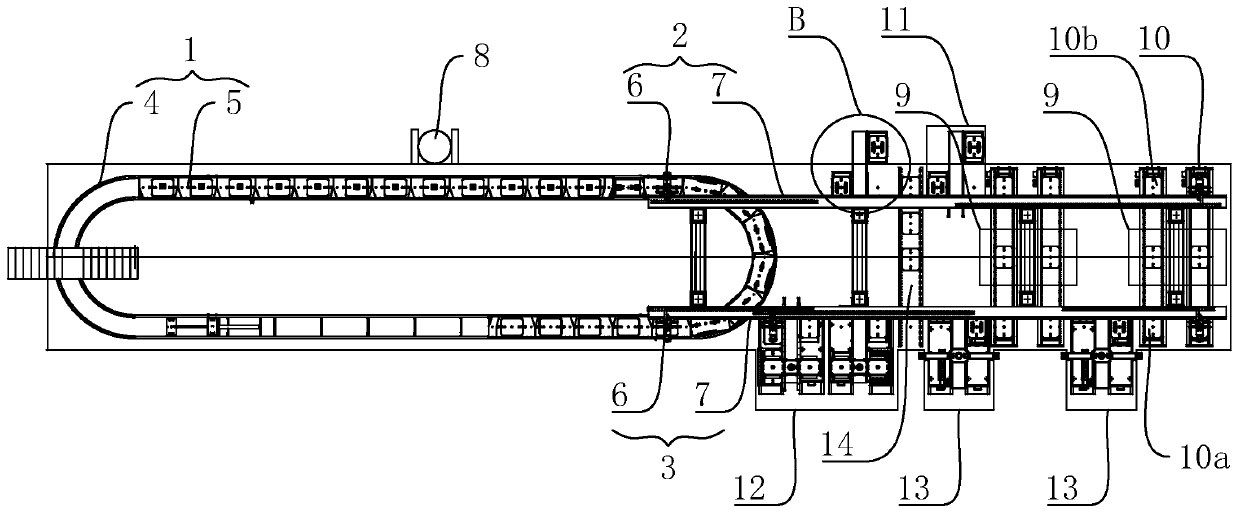

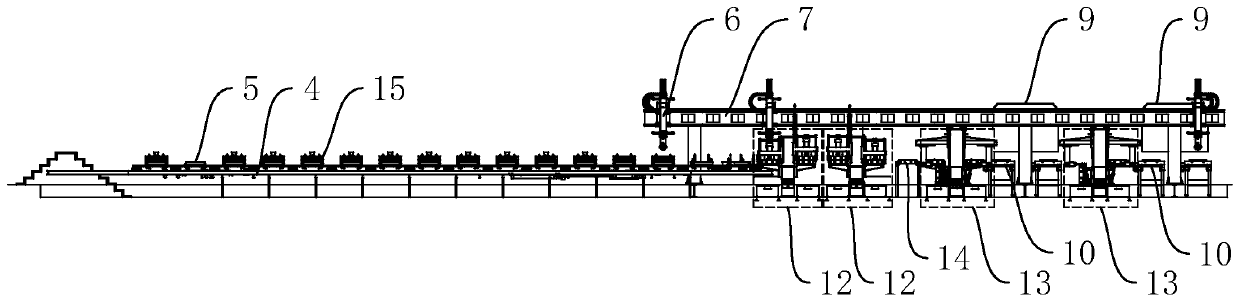

[0042] Such as figure 1 with 2 Shown: a sand casting production line, which is composed of a loop line 1, two parallel packing lines 2 and unpacking lines 3, the loop line 1 is set at one end of the packing line 2 and unpacking line 3, The packing point and unpacking point of the loop line 1 are set corresponding to the ends of the packing line 2 and the unpacking line 3 respectively;

[0043] Such as figure 1 with 2 As shown: the loop line 1 is composed of a transport track 4 and a box-fitting trolley 5 arranged on the transport track 4 for placing sand boxes; a casting trolley 8 is provided on the outside or inside of the loop line 1; the boxing Both the line 2 and the box unloading line 3 are composed of a truss 7 and a sand box grasping structure 6 arranged on the truss 7 and moving along the truss 7;

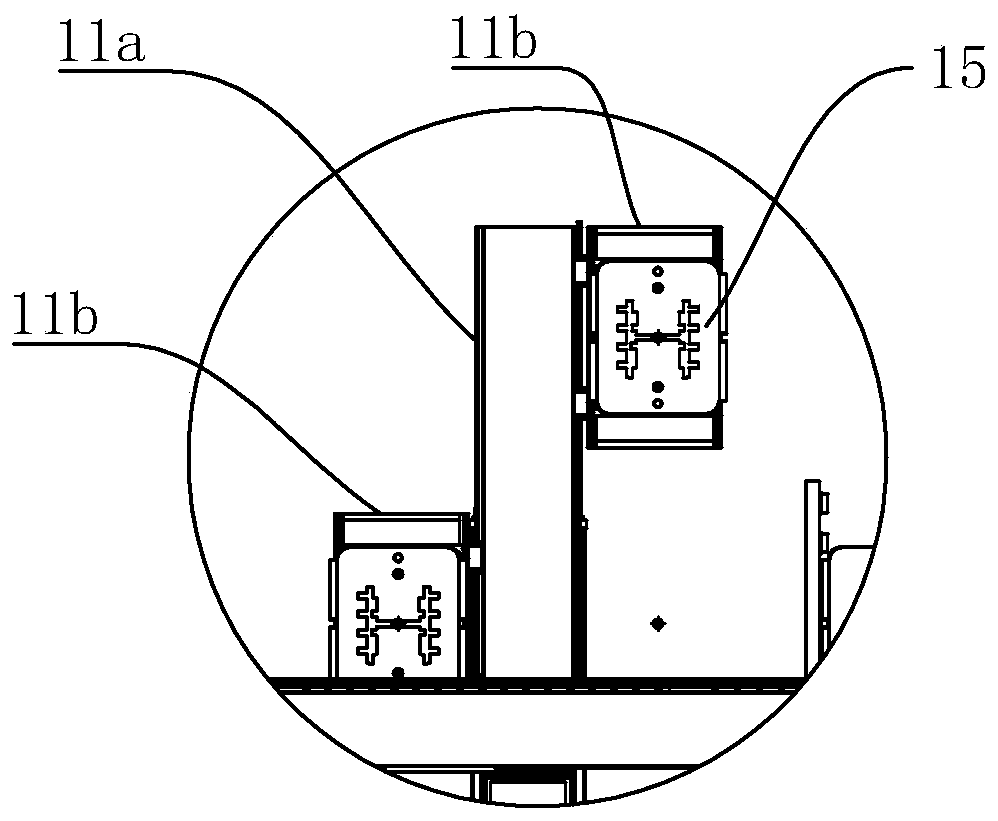

[0044] Such as figure 1 with 2 As shown: two molding machines 9 are arranged between the packing line 2 and the unloading line 3, and the molding machines 9 are distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com