Special machine tool for sealing surface machining of hard sealing valve bodies

A special machine tool and sealing surface technology, which is applied to metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult to meet the accuracy requirements of secondary clamping, manual grinding of products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

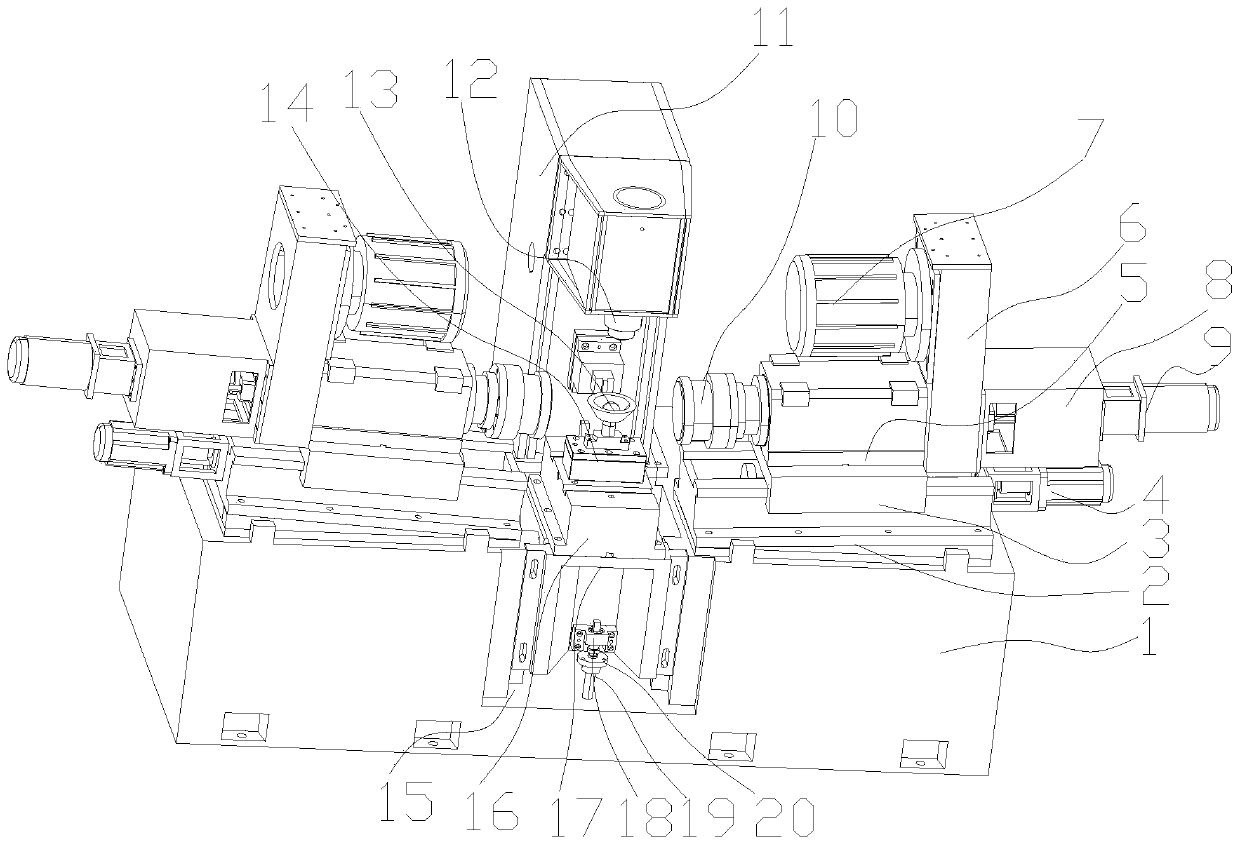

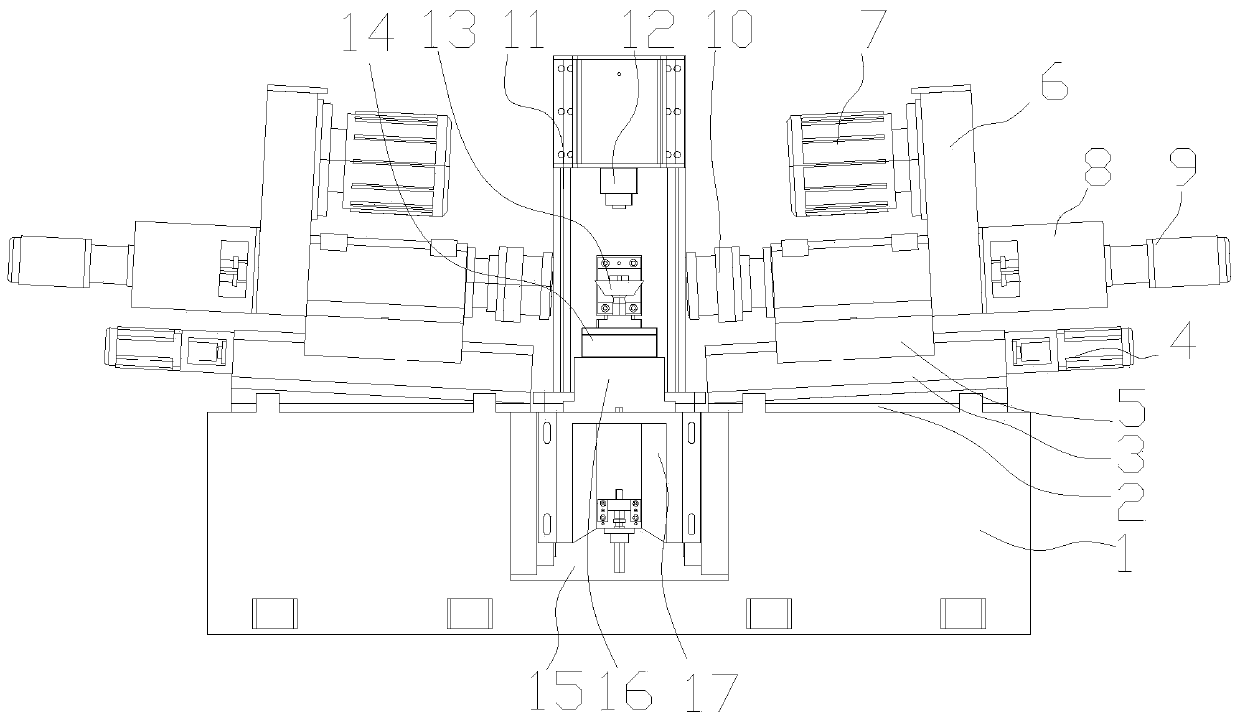

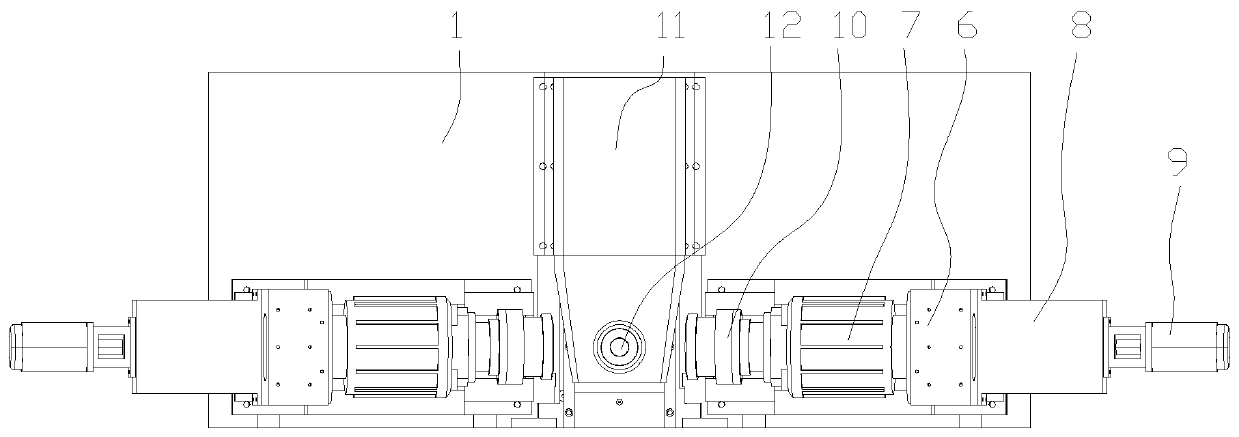

[0030] refer to Figure 1 to Figure 12 The shown special machine tool for processing the sealing surface of a hard-sealed valve body includes a base 1 and a valve body positioning processing device arranged above the base 1. The valve body positioning processing device is composed of a valve body for positioning the valve body. Body positioning device and its valve body processing device for processing the end face of the valve body, the valve body positioning device is set above the center position of the upper end face of the base 1, and the valve body processing device is distributed by mirror image It is composed of adjustable valve body processing mechanisms on both sides of the valve body positioning device, and each of the adjustable valve body processing mechanisms is composed of an adjustable support mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com