Universal self-sealing and self-opening-and-closing coupler for vacuum adsorption system

A vacuum adsorption system and self-sealing technology, applied in the field of mechanical processing, can solve the problems of low degree of automation, insufficient reliability and safety, etc., and achieve the effect of simple structure, low cost and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

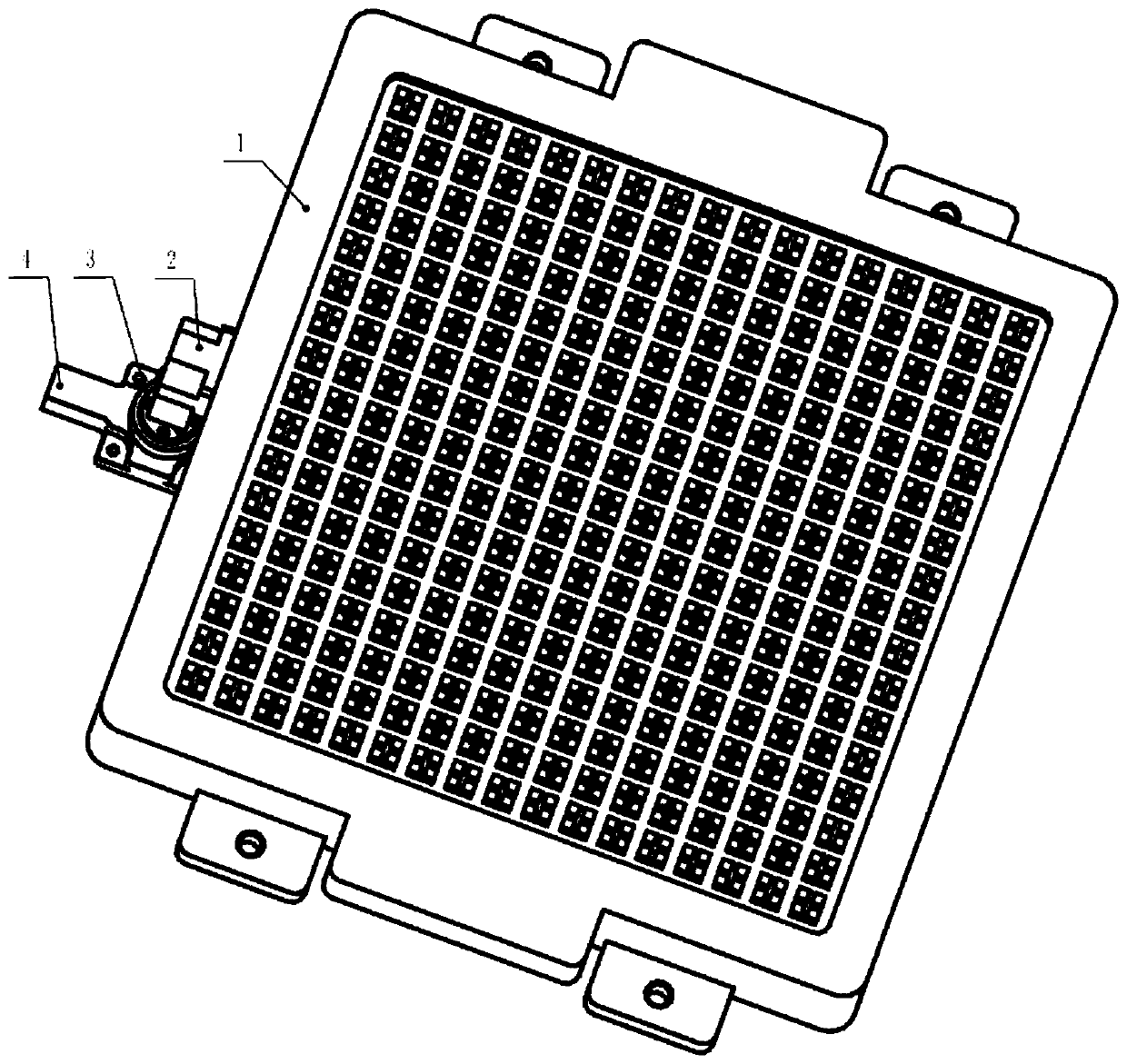

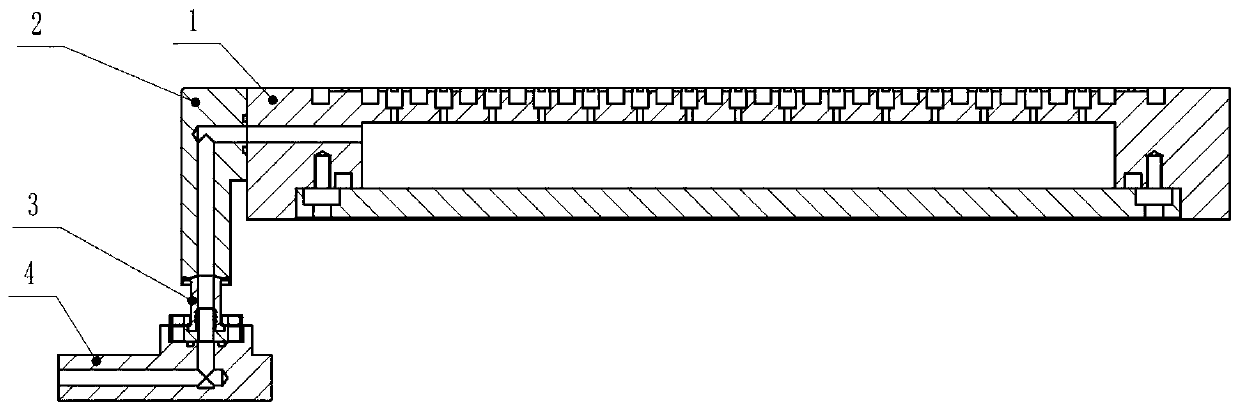

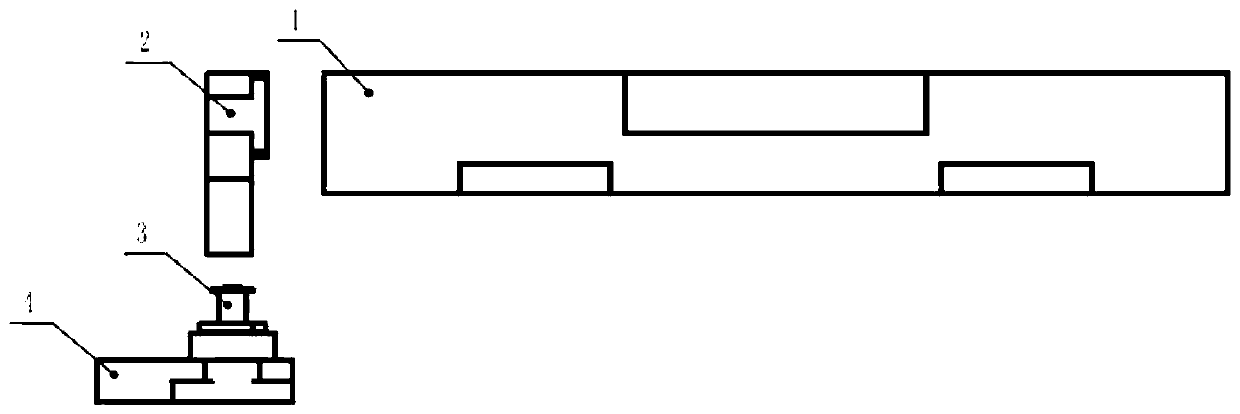

[0018] refer to Figure 1-Figure 5 . In the preferred embodiment described below, a universal self-sealing and self-opening coupling for a vacuum suction system includes a disk end connector 2 connected to the vacuum channel of the vacuum suction cup assembly 1 and a mounting seat fixedly installed on the machine tool table 4. Among them: the mounting base 4 is formed with a horizontal through vertical through hole, and a stepped hole is formed on the vertical through hole of the mounting base 4, and the step hole is fixed with a self-sealing joint 3, and the self-sealing joint 3 and the mounting base 4 form a self-sealing self-sealing joint. The opening and closing joint fixing part is assembled into a self-sealing self-opening and closing movable joint part that passes through the self-sealing disc-end connector 2 pipeline and communicates with the hollow vacuum cavity of the vacuum suction cup assembly 1. When the machine tool is working, under the action of atmospheric pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com