Heating plate mounting and moving mechanism

A technology of moving mechanism and heating plate, which is applied in the field of hot plate welding machine, can solve the problems that affect the processing accuracy and service life of the heating plate, and the installation and fixed structure of the heating plate cannot meet the requirements of automatic disassembly and replacement at the same time, so as to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

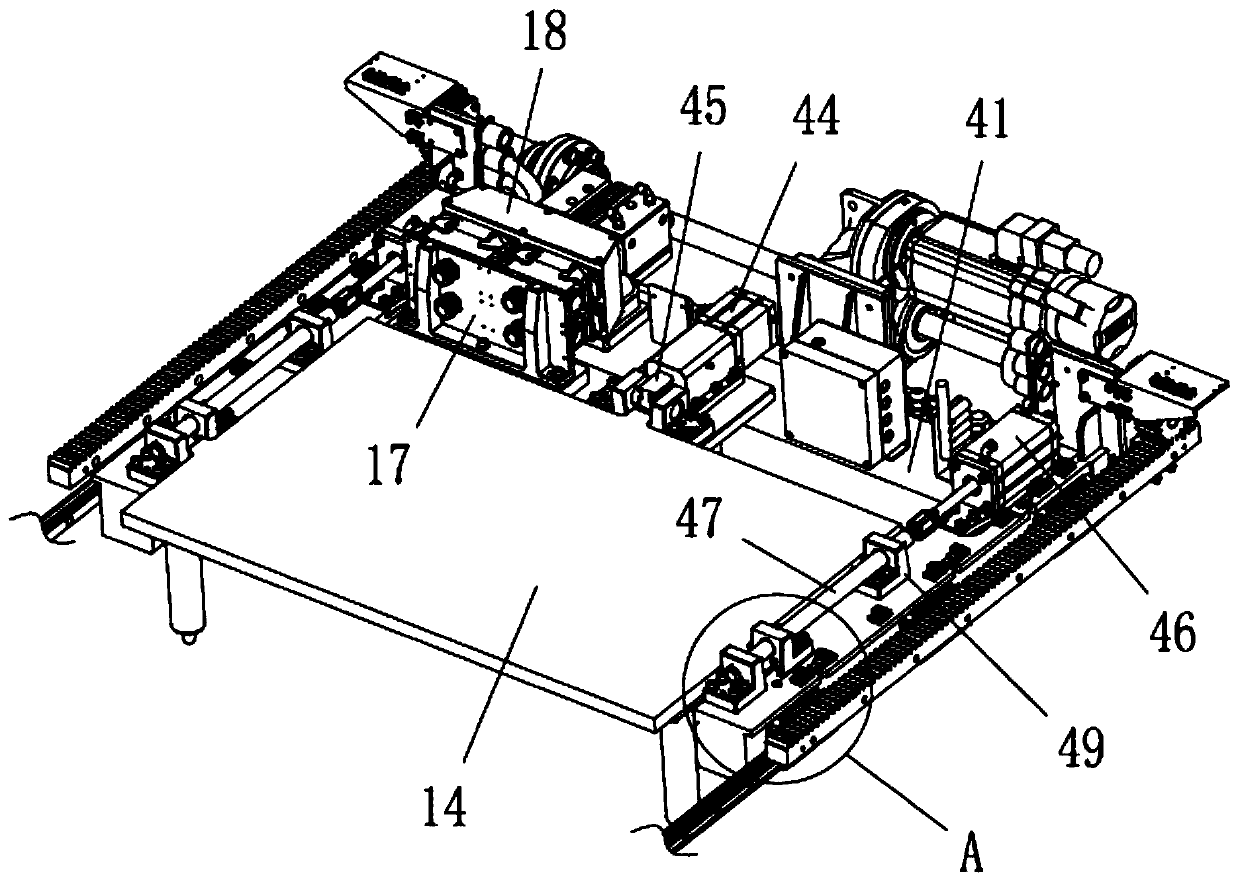

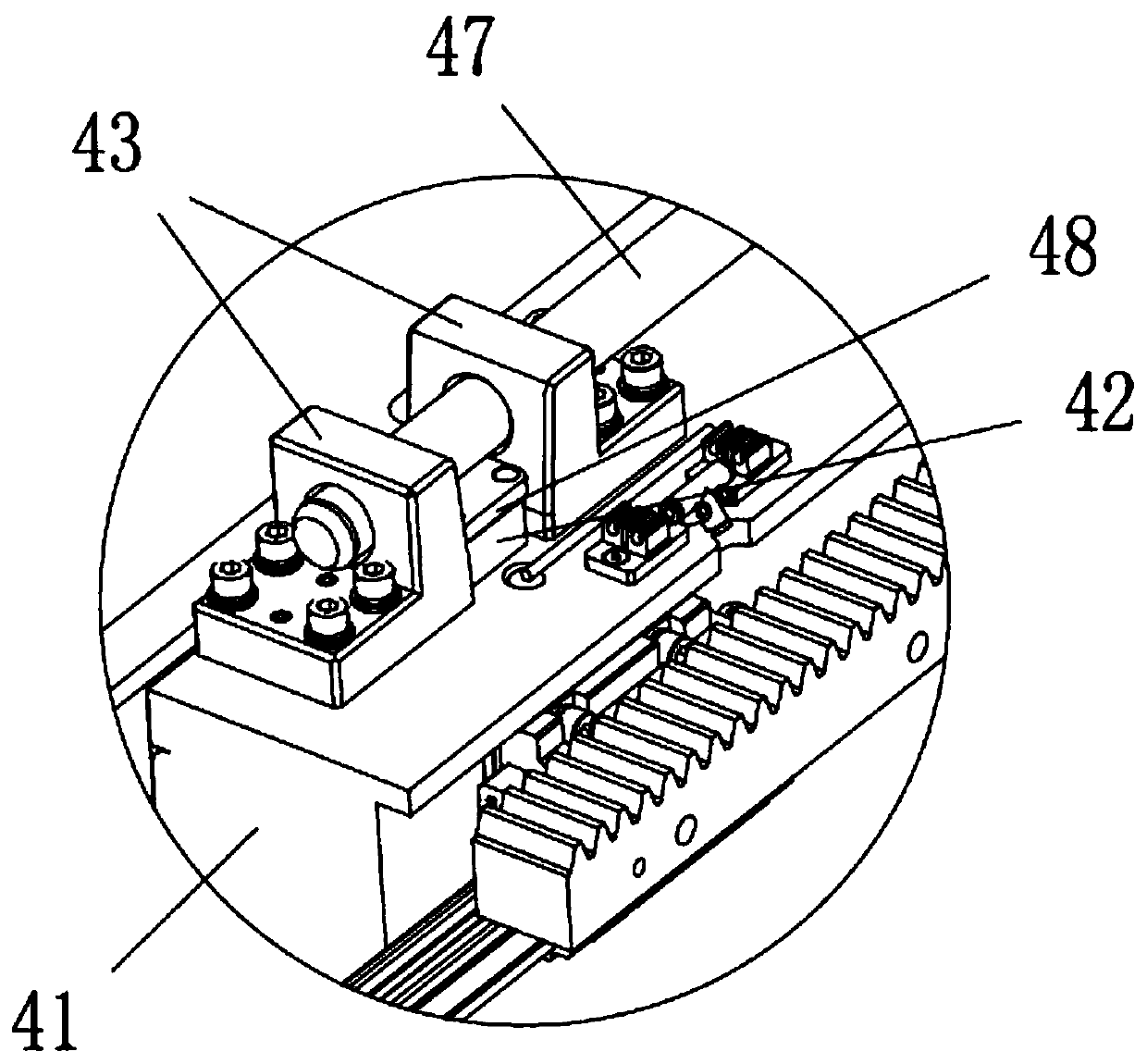

[0014] Such as Figure 1-2 As shown, the heating plate installation and moving mechanism of the present invention includes a hot plate moving frame 41, a heating plate and a forward drive assembly, the forward drive assembly drives the hot plate mobile frame 41 to move back and forth, and the forward drive assembly includes a servo motor, Reduction box, transmission shaft and rack, tooth rack is arranged on the left and right sides of hot plate mobile frame 41, and servo motor drives transmission shaft to rotate through reduction box, and the two ends of transmission shaft all pass gear and hot plate mobile frame 41 left and right sides rack fit.

[0015] The rear side and the left and right sides of the heating plate 14 all have an outwardly protruding ear portion 42, and the hot plate moving frame 41 is provided with 3 sets of hot ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap