A 4x4 electromechanical hydraulic all-wheel steering device

An all-wheel and steering lever technology, applied in mechanical steering gears, electric steering mechanisms, mechanical steering mechanisms, etc., can solve the problem of the response characteristics and impact resistance of the follow-up steering axle affecting vehicle handling stability, safety, and complex application environments. , harsh environment and other problems, to achieve the effect of small occupied space, safe and reliable system, and reasonable structure layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0075] In this article, if there is no special explanation, when it comes to formulas, " / " means division, and "×" and "*" mean multiplication.

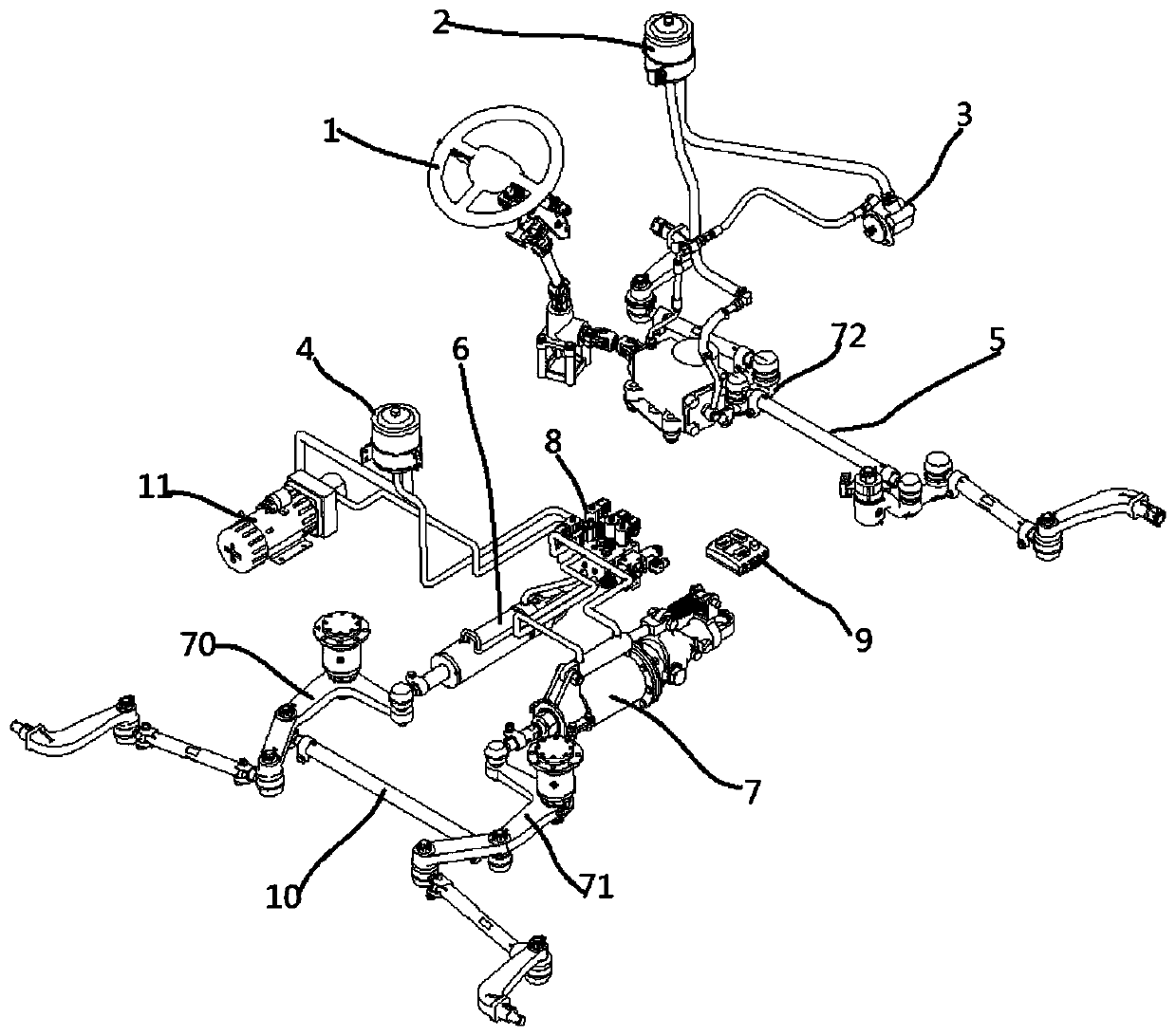

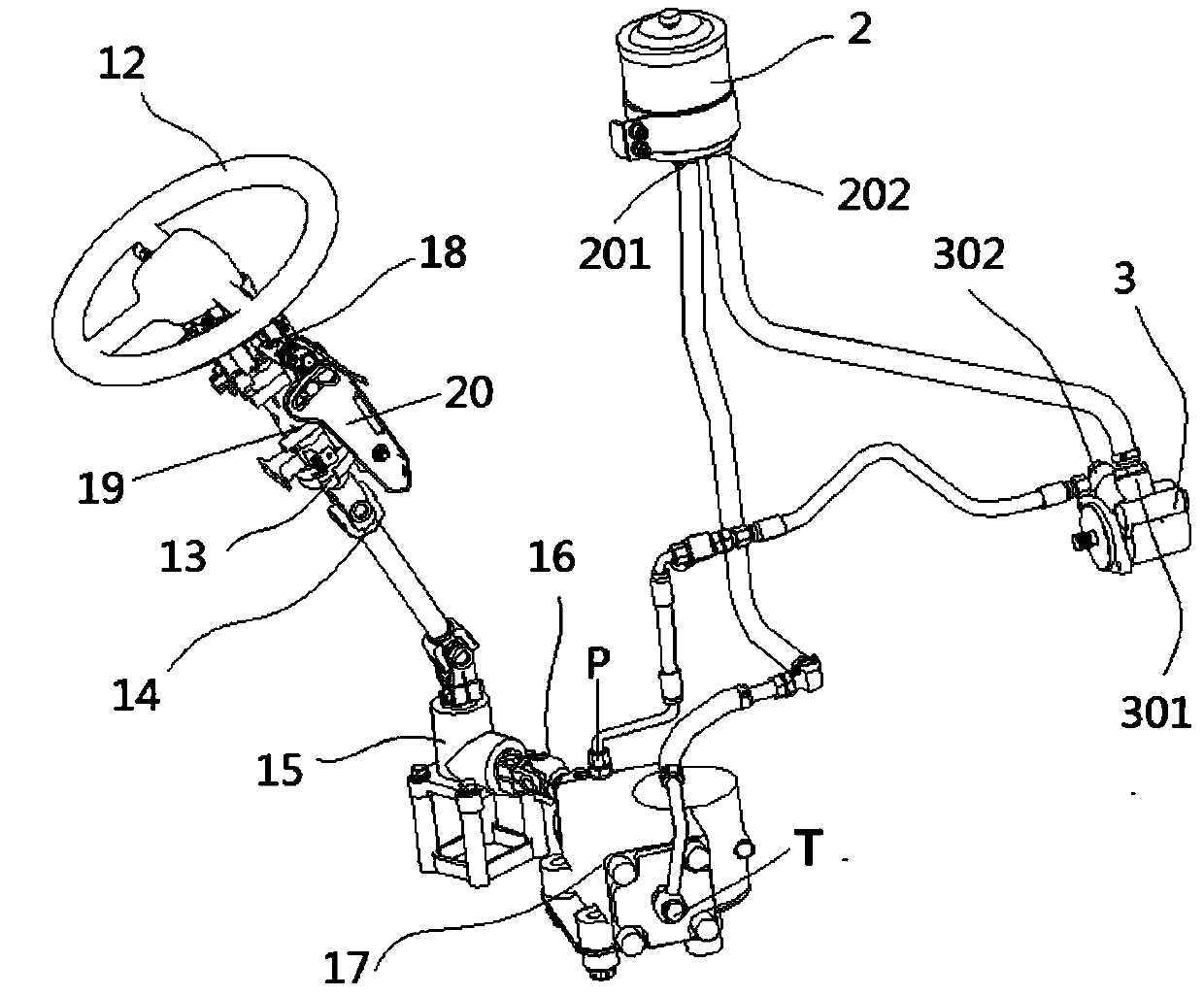

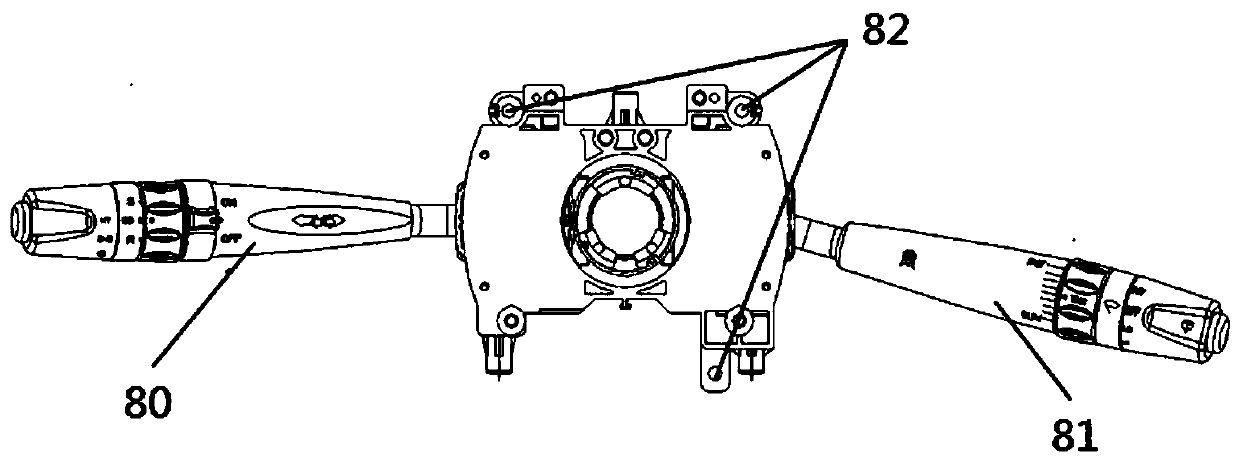

[0076] In order to solve the problems in the prior art, the present invention provides a high-reliability electromechanical hydraulic all-wheel steering system and its rear axle self-aligning and locking device, especially a 4X4 electromechanical hydraulic all-wheel steering system. The all-wheel steering device of the system adopts hydraulic power-assisted mechanical steering on the front axle, and the rear axle uses an electronically controlled hydraulic cylinder to drive the steering of the rear axle. As a preference, the high-reliability 4X4 electromechanical-hydraulic all-wheel steering system and its rear axle passive self-aligning and locking device are suitable for wheeled vehicles of mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com