Semi-organic-semi-inorganic silicon steel sheet coating solution for welding, preparation method and application

A semi-inorganic and silicon steel sheet technology, which is applied in the field of semi-organic-semi-inorganic silicon steel sheet coating solution and preparation, can solve problems such as affecting the efficiency of acid rolling on-line operation and roll consumption, and it is difficult to meet the individual needs of users, and achieve excellent comprehensive performance. , The effect of improved mechanical stability and uniform film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

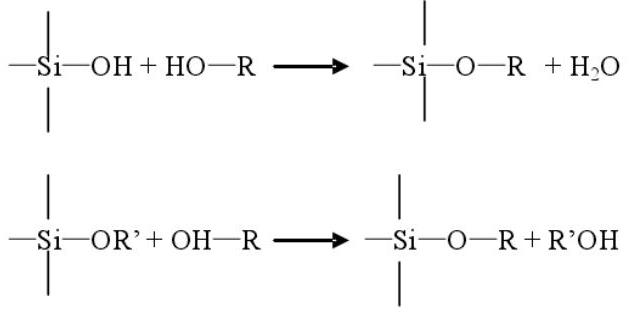

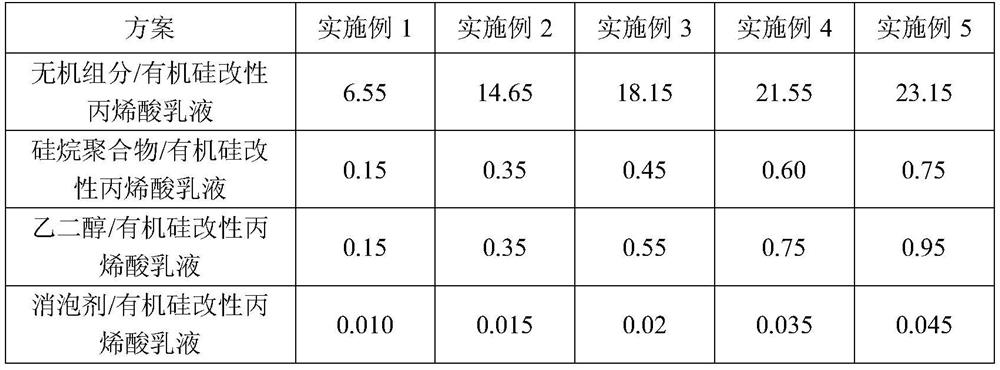

[0036] The semi-organic-semi-inorganic silicon steel sheet coating solution with good weldability provided by the present invention is composed of inorganic components, organosilicon modified acrylic acid emulsion, silane polymer, ethylene glycol, and defoamer in a mass ratio of (8~ 24): 1: (0.1 ~ 0.8): (0.1 ~ 1): (0.01 ~ 0.05) composition, the specific ratio of each embodiment is shown in Table 1; the inorganic components include magnesium oxide 1 ~ 8 parts, 14 to 29 parts of chromic anhydride, 0.1 to 0.8 parts of boric acid and 50 to 95 parts of water, the specific proportions are shown in Table 2; the organosilicon-modified acrylic emulsion is polydimethylsiloxane according to 2% mass ratio It is added to pure acrylic emulsion for polycondensation, wherein the mass ratio of hard monomer methyl methacrylate, soft monomer ethyl acrylate and crosslinking monomer N-methylol acrylamide in pure acrylic emulsion is 48:49:3 , the emulsifier is a complex of 0.5 parts of sodium laury...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating mass | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com