A kind of pt-ru bimetallic nano-catalyst and preparation method thereof for catalytic wet oxidation of high-concentration organic wastewater

A catalytic wet oxidation, bimetallic nanotechnology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, oxidized water/sewage treatment, etc. Catalyst activity is not high, to achieve the effect of improving catalytic oxidation ability, long service life, and acid resistance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

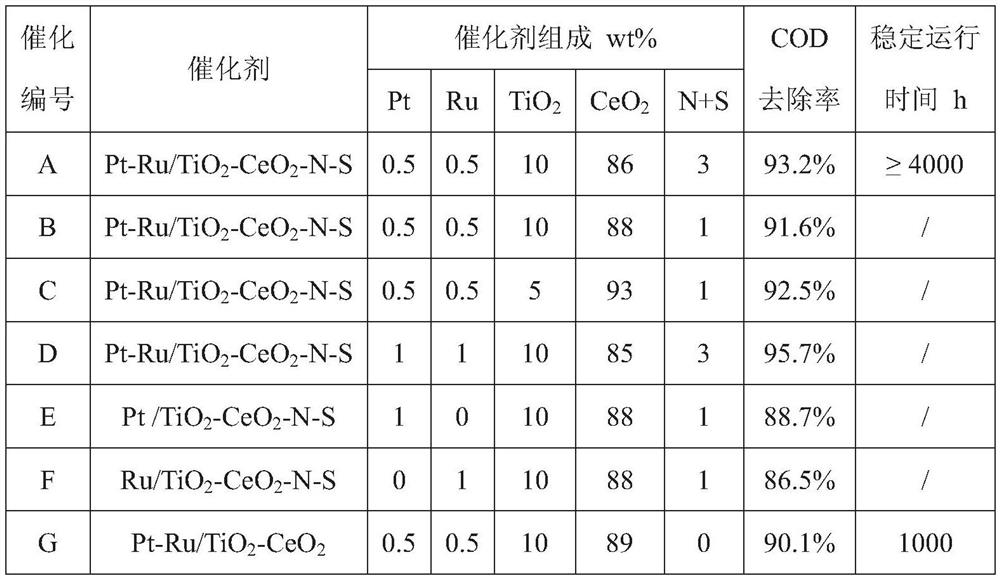

Examples

Embodiment 1

[0039] A method for preparing a Pt-Ru bimetallic nano-catalyst for catalytic wet oxidation of high-concentration organic wastewater, comprising the following steps:

[0040] (1) 6.00g Ti(SO 4 ) 2 with 43.42g Ce(NO 3 ) 3 ·6H 2 O was dissolved in 100ml deionized water to prepare solution I;

[0041] (2) 39.75g Na 2 CO 3 Dissolve in 100ml deionized water to make solution II;

[0042] (3) Add solution I and solution II side by side, stir and mix, age at room temperature for 8 hours, then transfer to a hydrothermal kettle, age at 120°C for 16 hours, then filter, wash, dry at 100°C for 12 hours, and dry at 600°C Roasted for 4 hours to obtain TiO 2 -CeO 2 composite oxides;

[0043] (4) Dissolve 1.27g of thiourea in 20ml of deionized water to form solution III, and dissolve TiO 2 -CeO 2 The composite oxide was added to solution III, left statically for 2 hours, then dried at 60°C for 12 hours, and calcined at 400°C for 3 hours in an inert gas atmosphere to obtain nitrogen ...

Embodiment 2

[0046] The preparation process is the same as in Example 1, except that Ce(NO 3 ) 3 ·6H 2 O addition is 44.43g, and Na in step (2) 2 CO 3 The add-on of thiourea is 40.49g, and the add-on of thiourea is 0.42g in step (4). This catalyst number is B.

Embodiment 3

[0048] Preparation process is the same as embodiment 1, just Ti(SO 4 ) 2 The addition amount is 3.00g, Ce(NO 3 ) 3 ·6H 2 O addition is 46.96g, and Na in step (2) 2 CO 3 The add-on of thiourea is 38.36g, and the add-on of thiourea is 0.42g in step (4). This catalyst number is C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com