Automatic booster pump

A booster pump, automatic technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of inability to automatically start the booster pump, the pipeline cannot reach, the water flow cannot be reached, etc., to achieve diversified control, The effect of convenient living and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

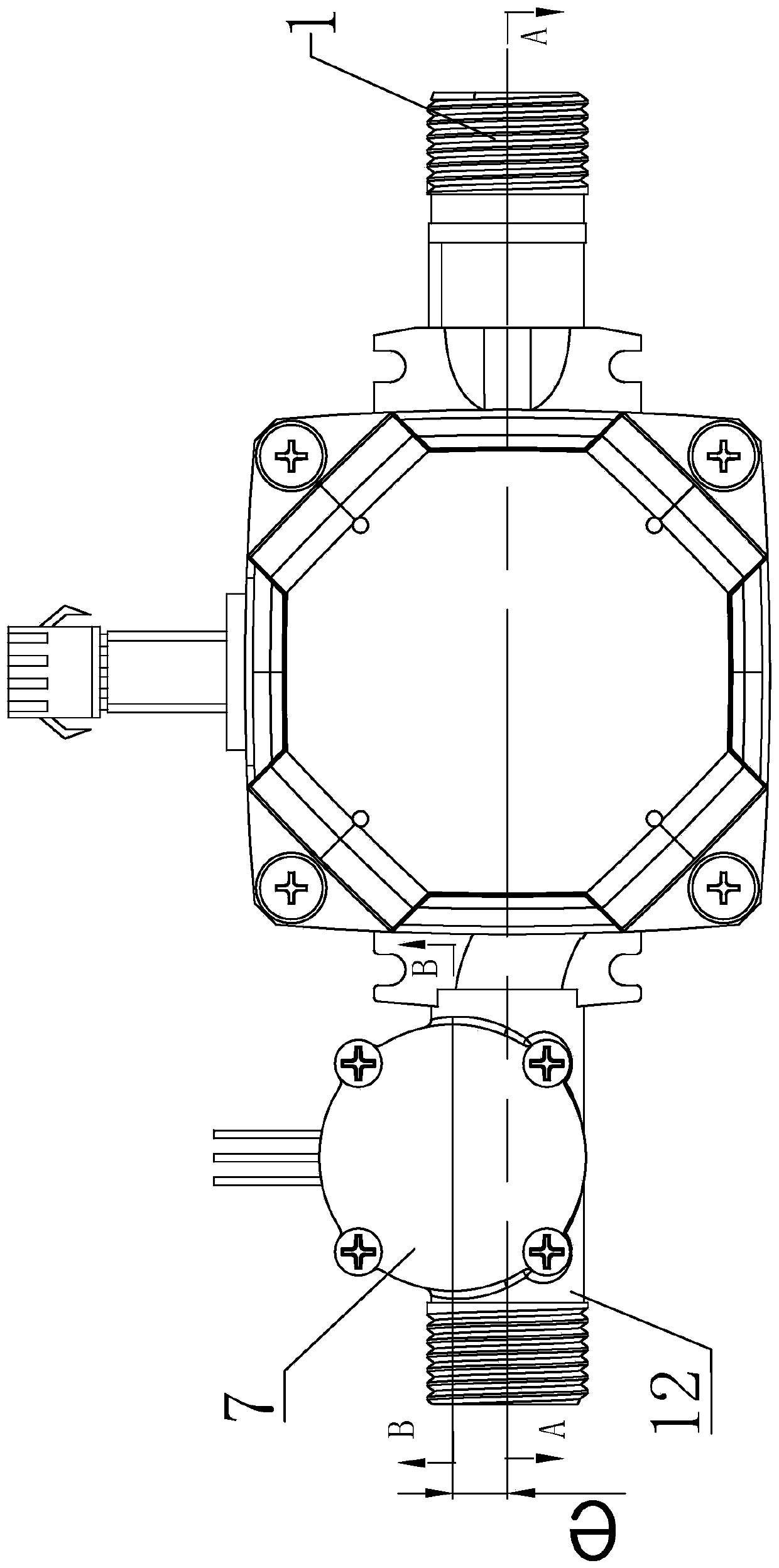

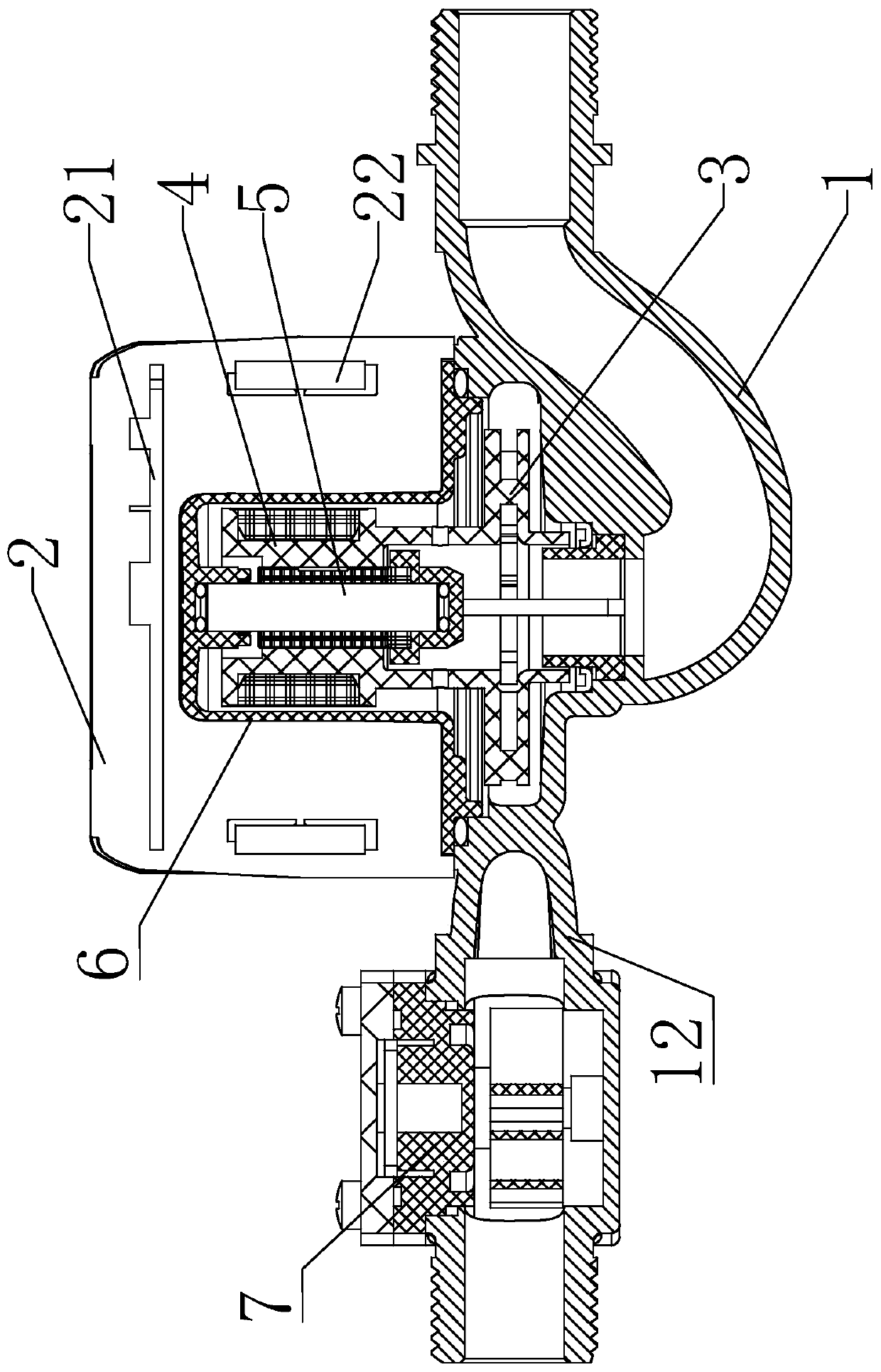

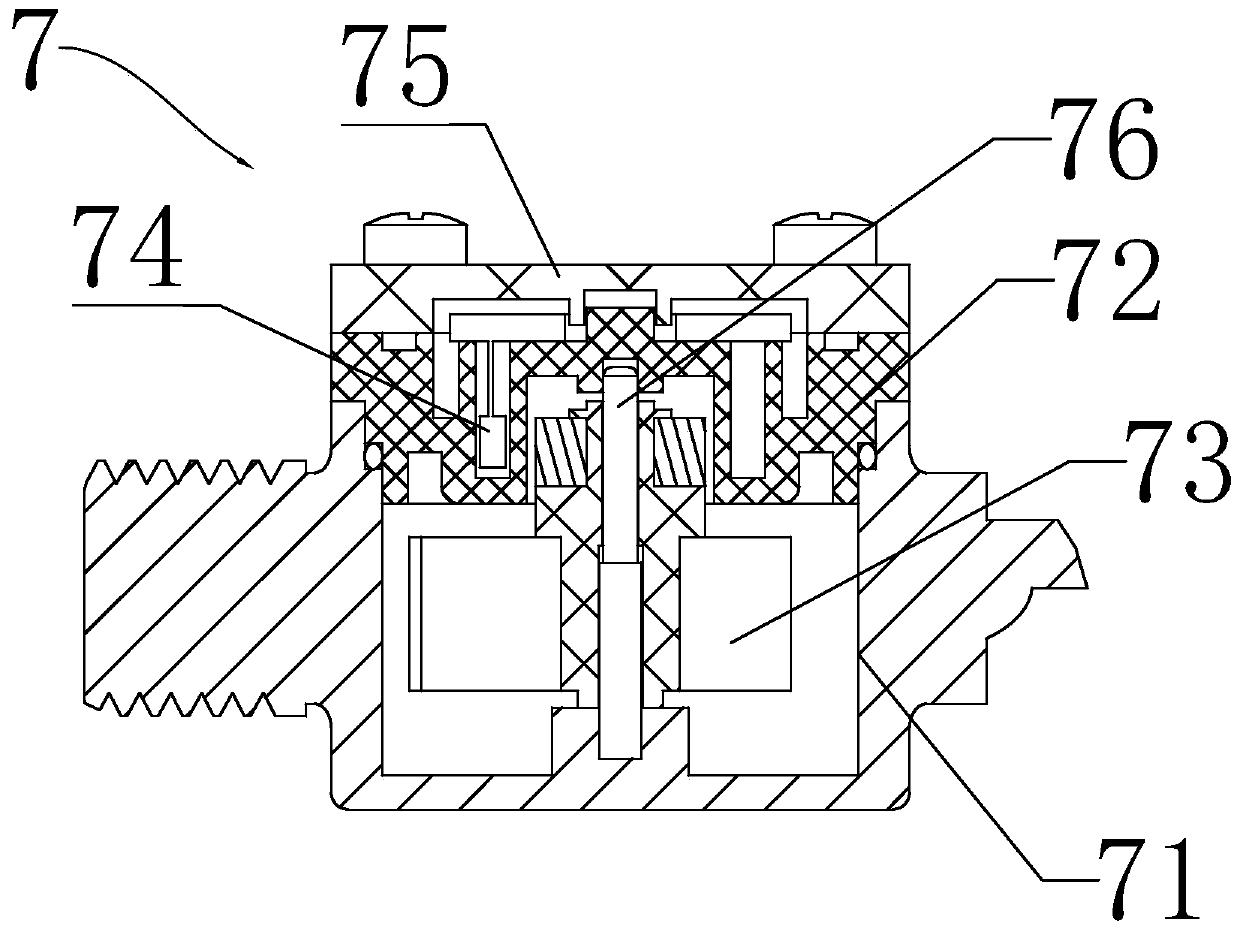

[0028] Example: such as Figure 1-5 As shown, the automatic booster pump has a motor 2 with a control board 21, and the casing 23 of the motor and the pump body 1 have corresponding flanges, which are fixedly connected by screws. The pump body is provided with an impeller 3 and the motor The rotor assembly 4 arranged inside is fixedly connected as a whole, and rotates around the fixed shaft 5 to achieve the effect of water flow boosting. The stator assembly 22 set on the periphery of the rotor assembly, and the control board 21 are covered by plastic molding compound (BMC) to form a whole, and the casing 23 of the motor is integrally formed by using the plastic packaging compound, and the rotor assembly and the stator assembly are separated by a shielding sleeve 6 isolation to ensure that the transported medium in the shielding sleeve does not leak.

[0029] Such as Figure 2-4 As shown, the pump body 1 is made of copper, and the water inlet pipe section or the water outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com