Decoration screw, screw decoration cover and decoration screw assembly

A technology for screw assemblies and decorative covers, applied in the directions of screws, threaded fasteners, connecting components, etc., can solve the problems of easy loosening, polluting the environment, time-consuming and cumbersome installation and disassembly, etc., and achieves the effect of tight plugging and not easy to play.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

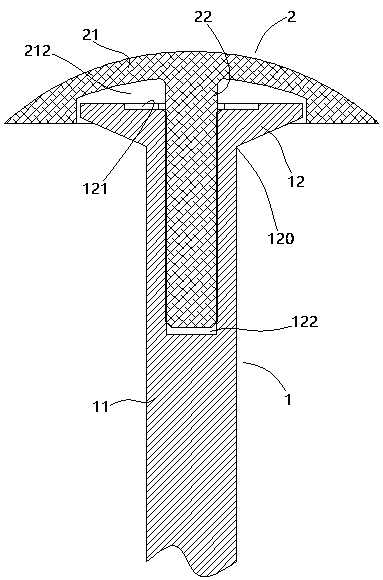

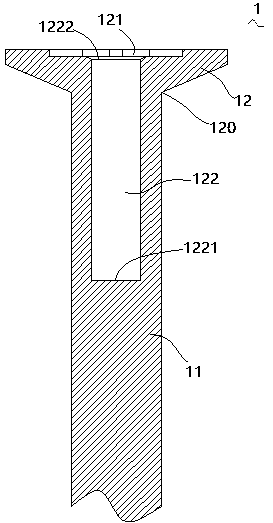

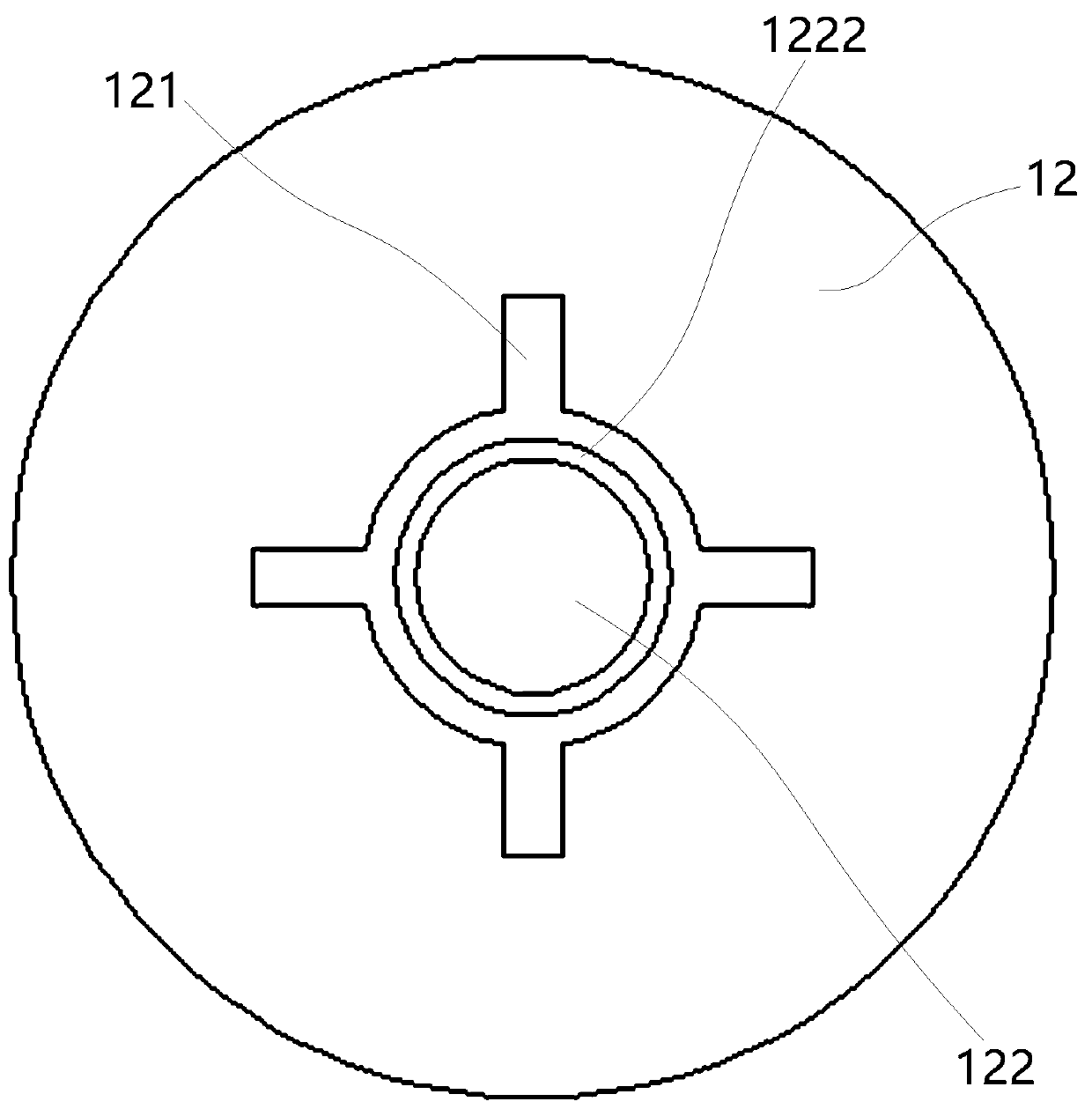

[0016] A decorative screw assembly of the present invention adopts the following technical scheme: as Figure 1-4 As shown, the decorative screw assembly includes a decorative screw 1 and a screw decorative cover 2, the decorative screw 1 includes a nail body 11, the outer surface of the nail body 11 is provided with external threads, and the external threads of the nail body 11 are the content of the prior art, and will not be repeated. . The upper end of nail body 11 has nail cap 12, and the lower end has nail head, and nail cap 12 is the existing common tapered nut 12, also can adopt cylindrical nail cap 12, all is prior art no longer repeats. The nail body is fully threaded and has a deep hole in the center of the head. The upper end of the nail cap 12 has a screwing groove 121 for screwing with a screwdriver, and the screwing groove 121 is an existing common inline or cross or rice-shaped, so that a screwdriver or a special screw tool can be used to tighten the screw. s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com