Bolt loosening and breakage monitoring device and bolt loosening and breakage monitoring method

A monitoring device and bolt technology, applied in the field of bolt loosening monitoring and bolt loosening monitoring device, can solve problems such as inconvenient monitoring methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

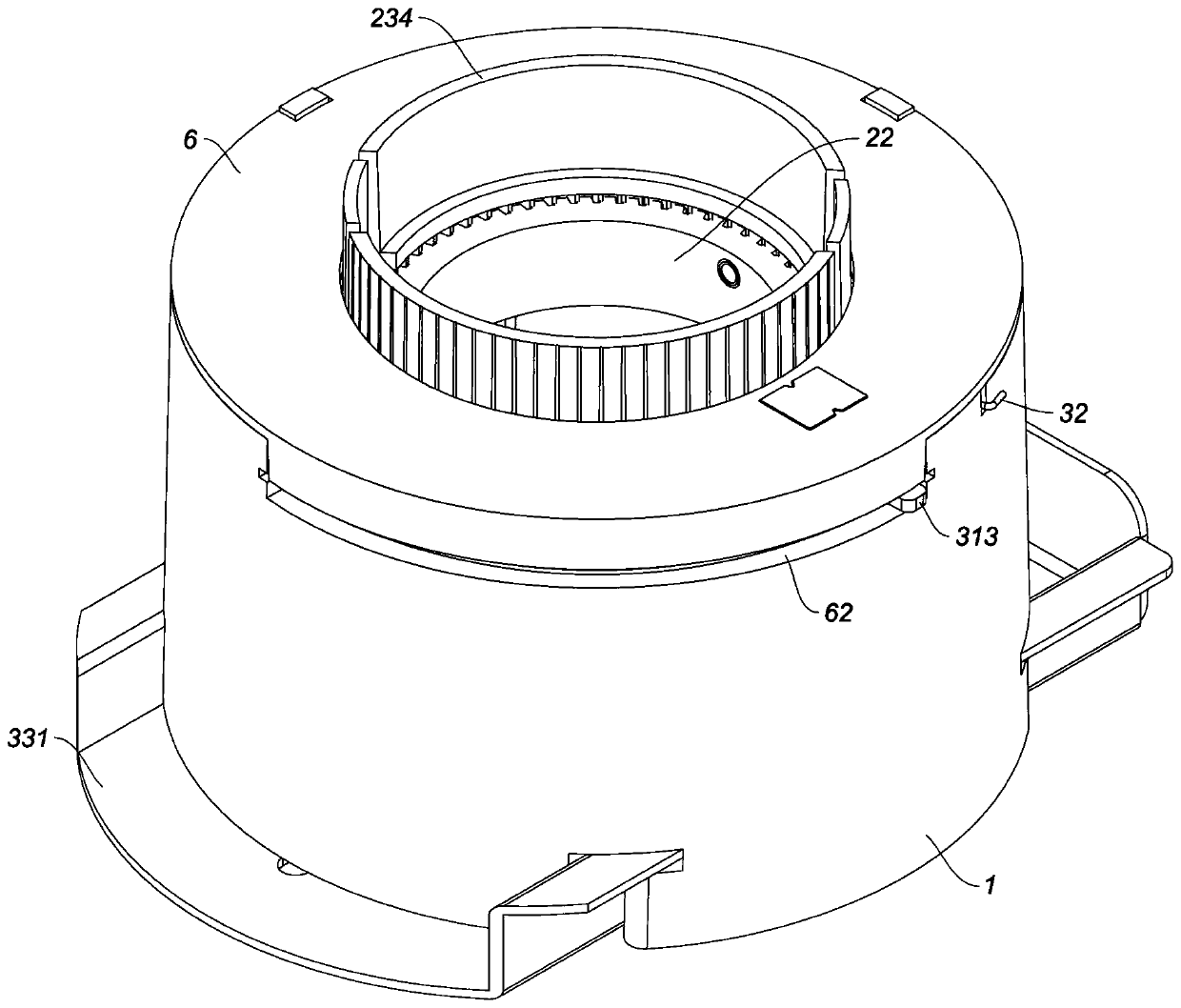

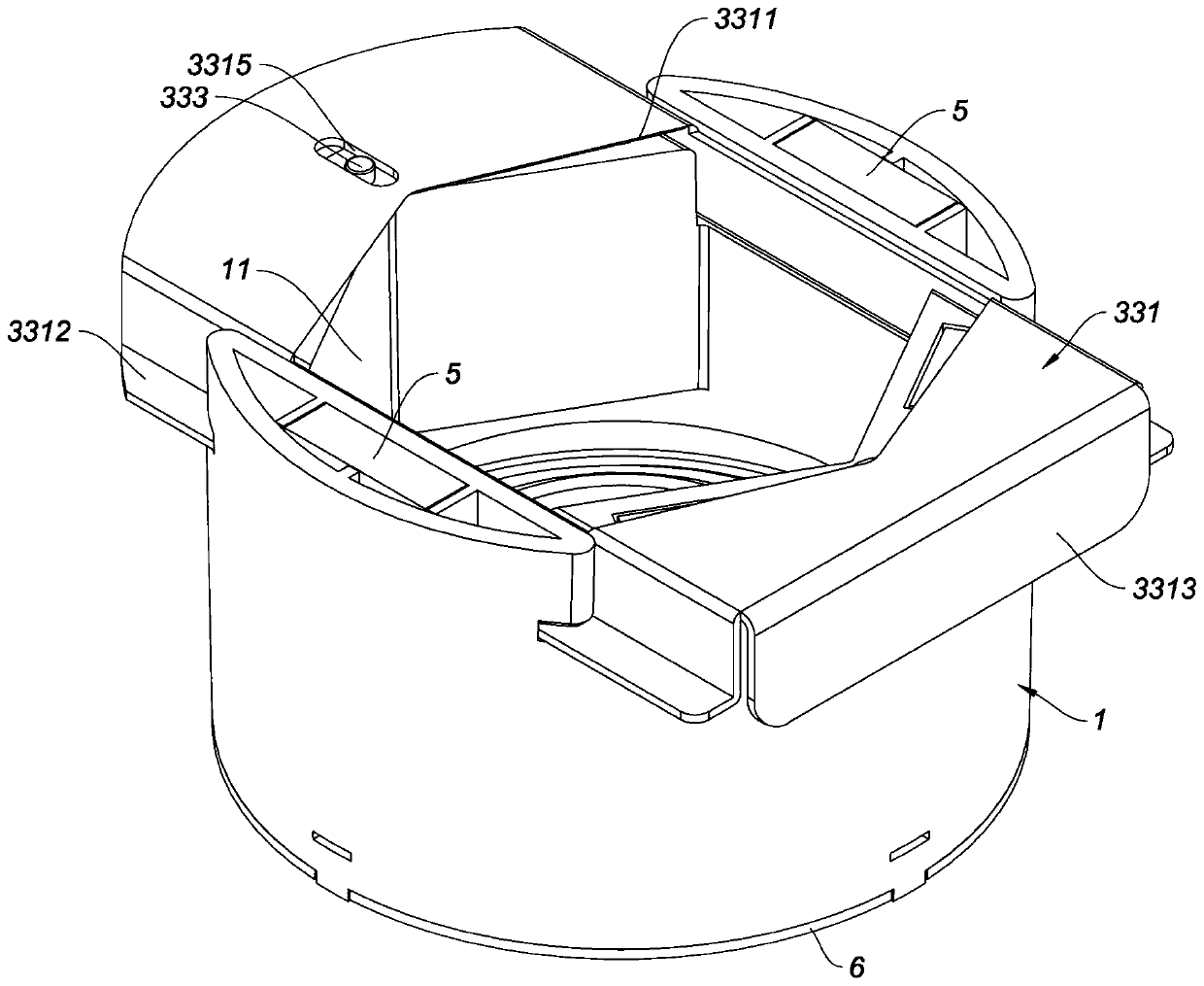

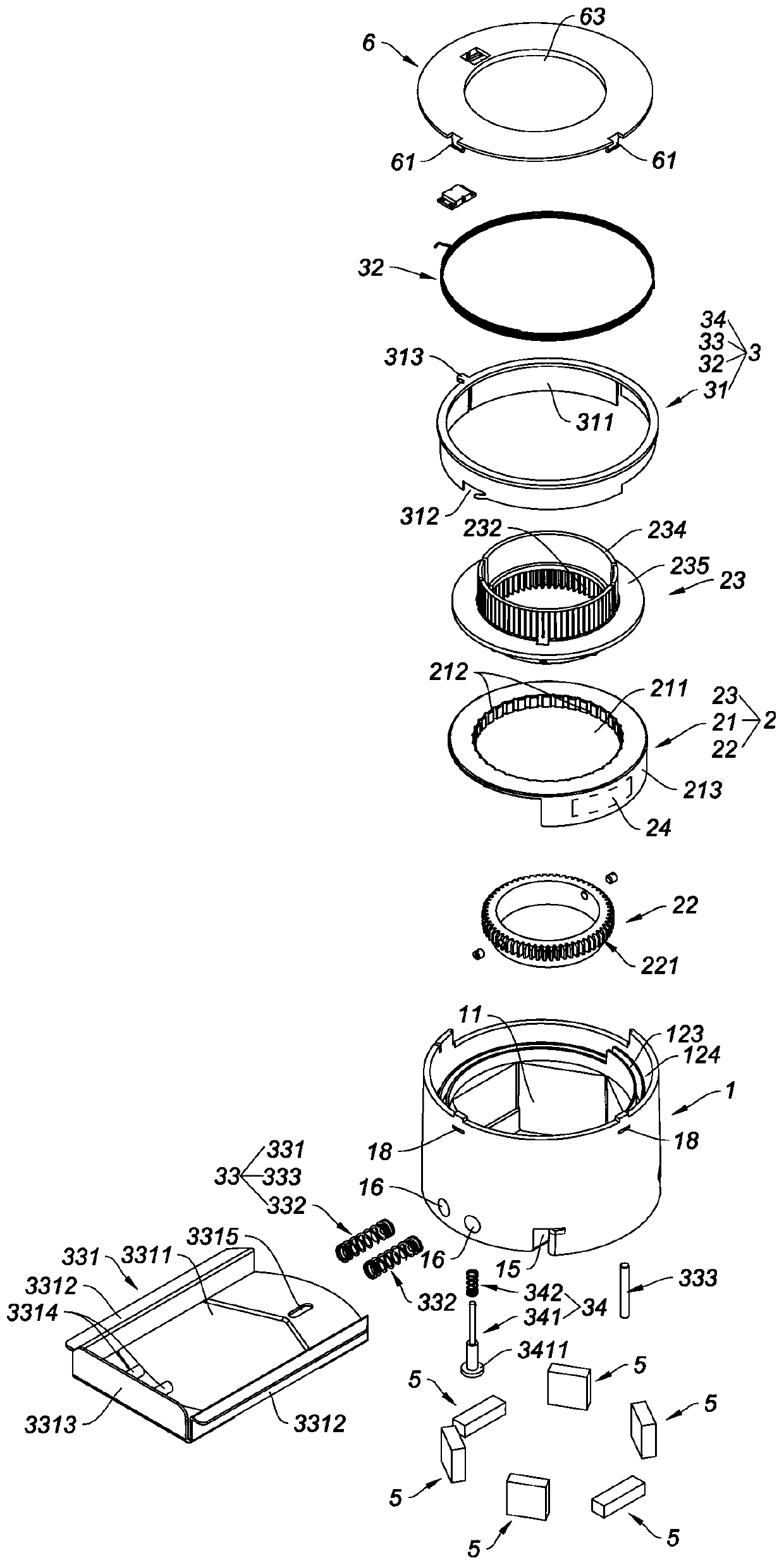

[0036] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, this embodiment is a bolt loosening monitoring device, including a housing 1, a loosening detection mechanism 2, and a fracture detection mechanism 3; wherein:

[0037] A sleeve through hole 11 is formed in the housing 1, and an installation recess 12 communicating with the sleeve through hole 11 is formed on the top surface of the housing 1, and a first rotation groove 121 and a second rotation groove 121 are formed in the installation recess 12. Rotation groove 122, the first rotation groove 121, the second rotation groove 122 are respectively arranged around the axis of the sleeve through hole 11, a first shielding area 123 is provided in the first rotation groove 121, and a first shielding area 123 is provided in the first rotation groove 121. A first blocking portion 125 is also formed, and the first blocking portion 125 is at the edge of the first shielding area 123; a second sh...

Embodiment 2

[0048] This embodiment is a method for monitoring bolt looseness, comprising the following steps:

[0049] 1) Install bolts and nuts on equipment or mechanisms;

[0050] 2) The stud fixing ring of a kind of bolt loosening monitoring device described in embodiment 1 is fixed on the stud part of the bolt, and then the sleeve through hole of the shell of the bolt loosening monitoring device is placed on the nut, As a result, the stud fixing ring is nested in the ring part of the transmission ring seat of the bolt loosening monitoring device, and the outer teeth of the stud fixing ring mesh with the inner teeth of the ring part of the drive ring seat;

[0051] 3) Use reading and writing equipment to monitor the bolt loosening monitoring device, during the period:

[0052] A) If the reading and writing equipment can read loose RFID electronic tags and broken RFID electronic tags, it means that the bolt is in the preset normal working state;

[0053] B) If the reading and writing ...

Embodiment 3

[0059] The difference between this embodiment and embodiment 2 lies in that the read-write device in step 3) is a fixed reader-writer, and the monitoring type is system real-time online or system periodic polling. This design enables the user to monitor the installed bolts at all times, so that when the bolts are loosened or broken, they can respond immediately to reduce losses.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com