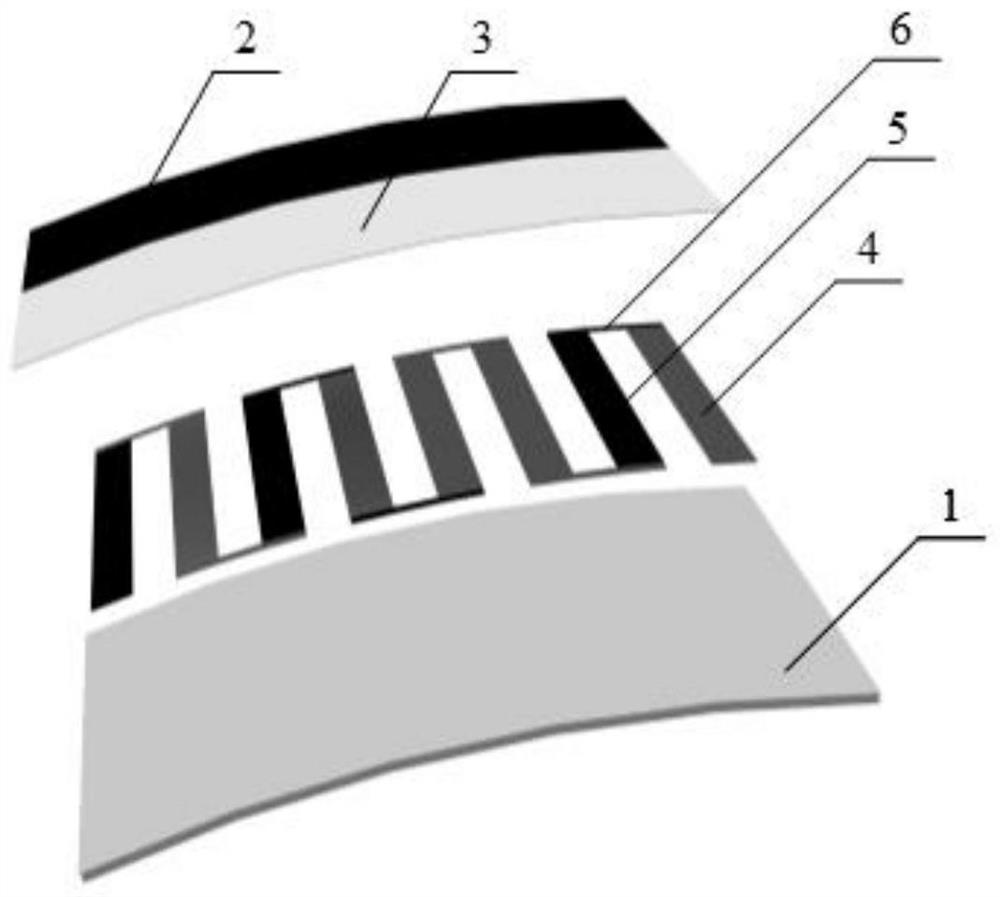

Ink printing preparation method and structure of light-assisted thermoelectric device

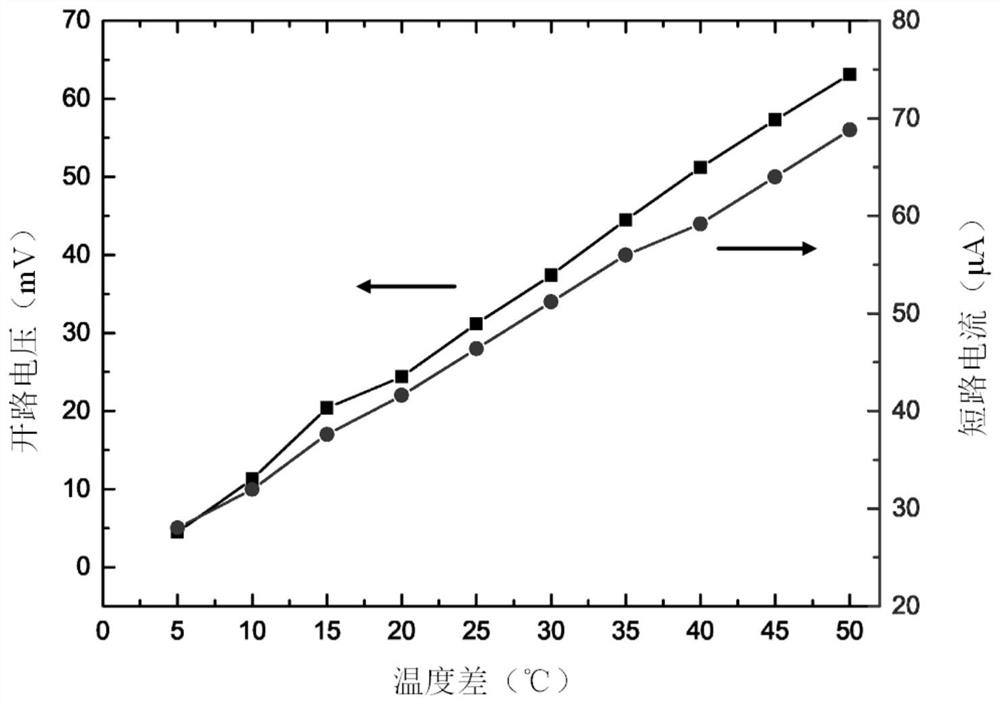

A thermoelectric device, light-assisted technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric device parts, inks, etc., can solve the problems of high cost and complex preparation process, achieve stable performance, excellent electrical properties, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides an ink-printed preparation method for light-assisted thermoelectric devices, and the specific steps are as follows:

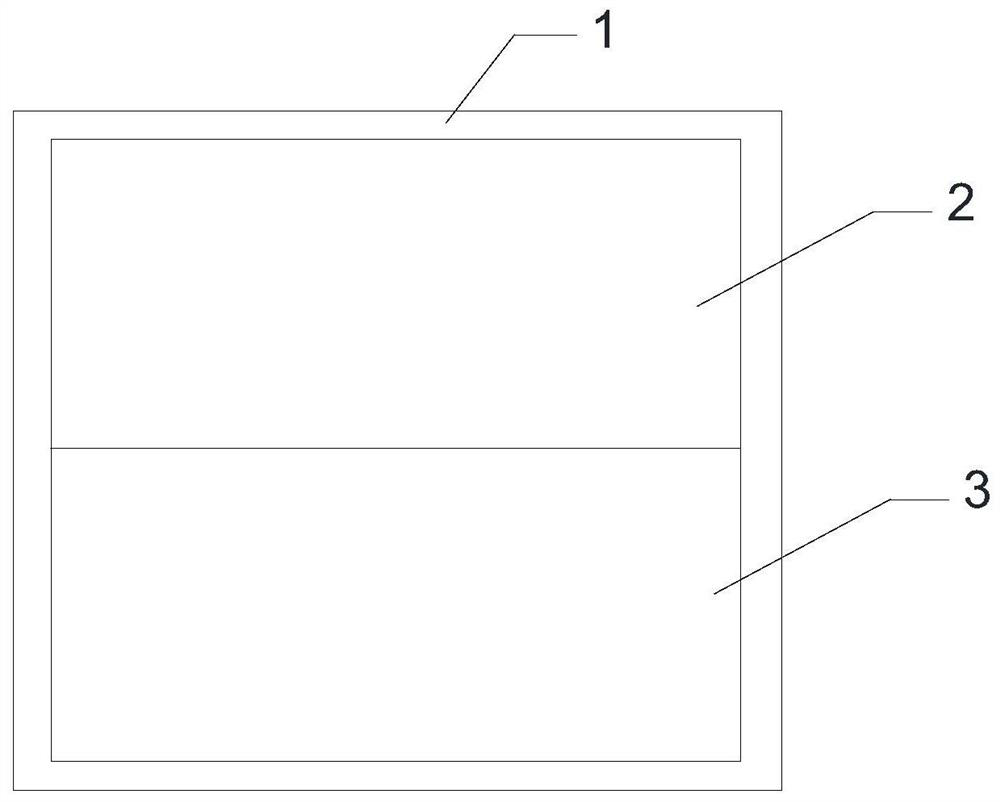

[0039] In step 1, polyimide is selected as the substrate of the light-assisted thermoelectric device, and the length of the substrate is 50 mm, the width is 40 mm, and the thickness is 150 μm.

[0040] Step 2, using Bi 2 Te 2.7 Se 0.3 As an N-type thermoelectric material, Sb 2 Te 3 As the P-type thermoelectric material, the powder particle size of the N-type thermoelectric material and the P-type thermoelectric material are both smaller than 37 μm.

[0041] Step 3, the epoxy resin selects bisphenol F epoxy resin and polypropylene glycol diglycidyl ether, and the two epoxy resins are mixed in a mass ratio of 1:1, wherein the epoxy value of bisphenol F epoxy resin is 0.58eq / 100g, the epoxy value of polypropylene glycol diglycidyl ether is 0.32eq / 100g; curing agent selects methyl hexahydrophthalic anhydride; catalyst selects 1...

Embodiment 2

[0048] This embodiment provides an ink-printed preparation method for light-assisted thermoelectric devices, and the specific steps are as follows:

[0049] In step 1, polyimide is selected as the substrate of the light-assisted thermoelectric device, and the length of the substrate is 50 mm, the width is 40 mm, and the thickness is 150 μm.

[0050] Step 2, using Bi 2 Te 2.7 Se 0.3 As an N-type thermoelectric material, Bi 0.6 Sb 1.4 Te 3 As the P-type thermoelectric material, the powder particle size of the N-type thermoelectric material and the P-type thermoelectric material are both smaller than 37 μm.

[0051] Step 3, the epoxy resin selects bisphenol F epoxy resin and polypropylene glycol diglycidyl ether, and the two kinds of epoxy resins are mixed in a mass ratio of 1:1, wherein the epoxy value of bisphenol F epoxy resin is 0.58 eq / 100g, the epoxy value of polypropylene glycol diglycidyl ether is 0.32eq / 100g; the curing agent selects methyl hexahydrophthalic anhydr...

Embodiment 3

[0058] This embodiment provides an ink-printed preparation method for light-assisted thermoelectric devices, and the specific steps are as follows:

[0059] In step 1, polyimide is selected as the substrate of the light-assisted thermoelectric device, and the length of the substrate is 50 mm, the width is 40 mm, and the thickness is 150 μm.

[0060] Step 2, using Bi 2 Te 2.7 Se 0.3 As an N-type thermoelectric material, Sb 2 Te 3 As the P-type thermoelectric material, the powder particle size of the N-type thermoelectric material and the P-type thermoelectric material are both smaller than 37 μm.

[0061] Step 3, the epoxy resin selects bisphenol F epoxy resin and polypropylene glycol diglycidyl ether, and the two kinds of epoxy resins are mixed in a mass ratio of 1:1, wherein the epoxy value of bisphenol F epoxy resin is 0.58 eq / 100g, the epoxy value of polypropylene glycol diglycidyl ether is 0.32eq / 100g; the curing agent selects methyl hexahydrophthalic anhydride; the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com