Tubular stent as well as preparation method and application thereof

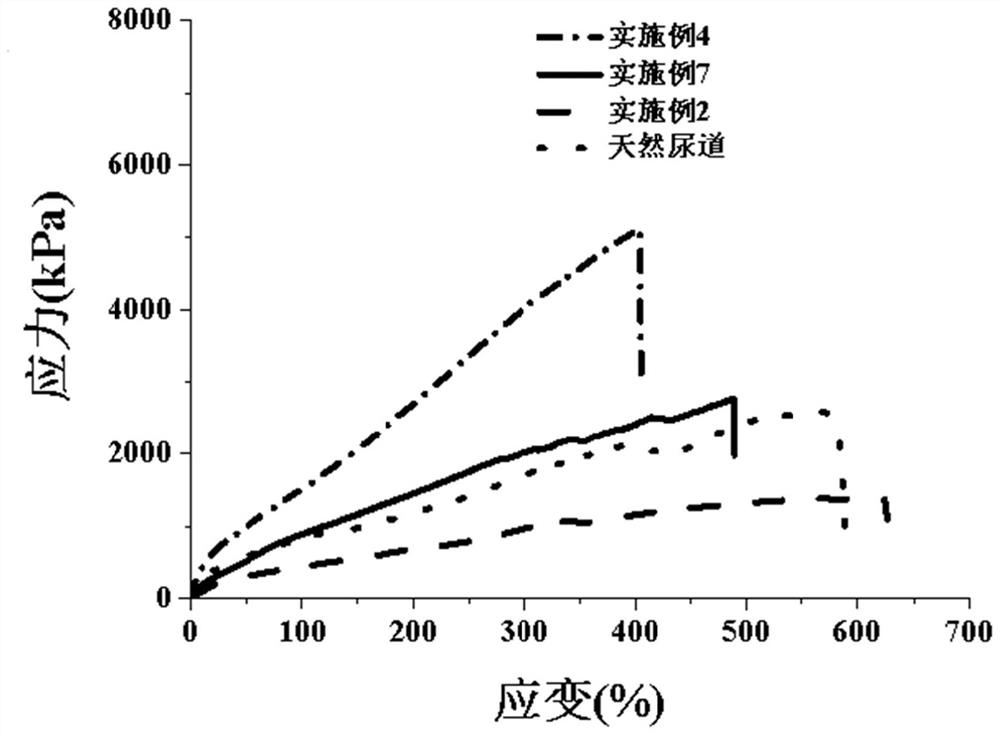

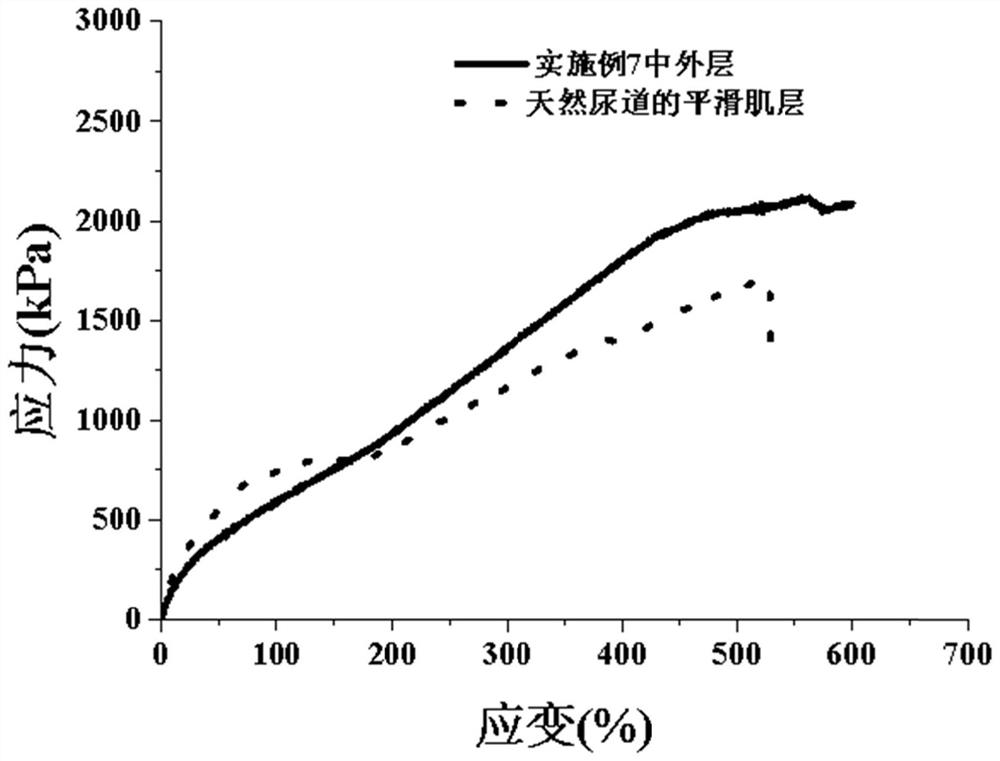

A tubular and spinning technology, which is applied in the field of materials, can solve the problems that the mechanical properties of urethral tissue are far from different, and cannot be treated with the urethra of young boys, and achieve the effect of simple and efficient preparation method and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The specific preparation method of the tubular stent of this example is as follows:

[0054] Preparation steps of spinning solution: Gelatine has a relative molecular mass of about 50,000 and is dissolved in hexafluoroisopropanol at room temperature for about 12 hours to reach a final gelatine concentration of 7% (w / v). PLLA had a number average molecular weight (Mn) of 420,000 and was dissolved in a 50 / 50 (v / v) mixture of dimethylformamide and dichloromethane at room temperature for about 12 hours to achieve 8% (w / v) Final PLLA concentration.

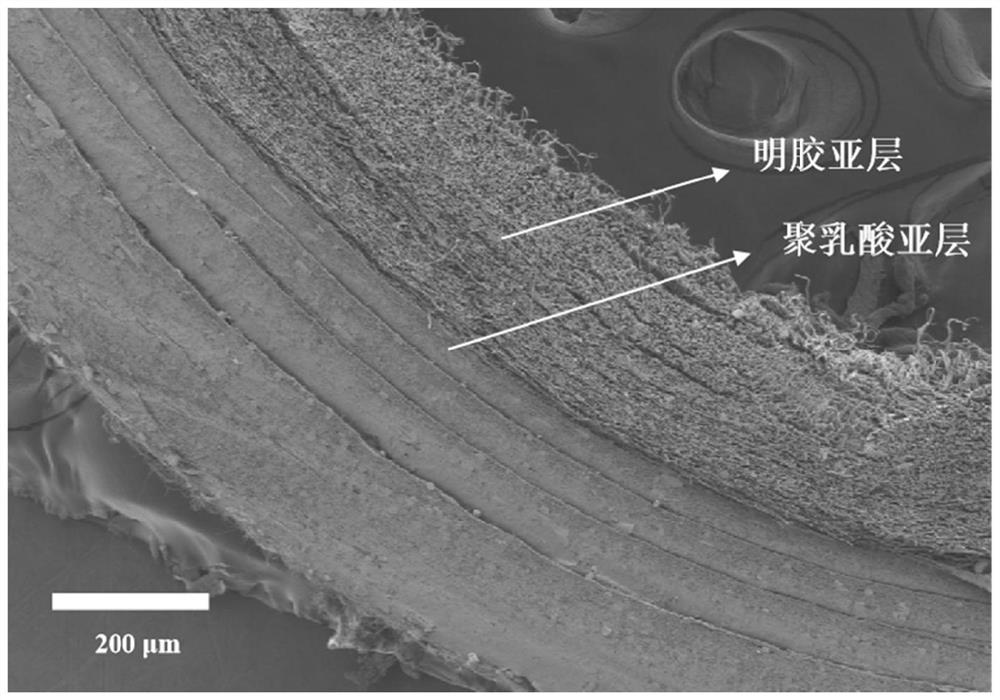

[0055] The gelatin layer of the tubular scaffold was prepared by the solution blow-spinning method: suck the dissolved gelatine solution with a 10 ml spinning syringe, fix the syringe in the precision syringe pump, set the feeding rate to 120 μL / min, press the air and gelatine solution The lines are all connected to the spray device, and the nozzle system can be placed at various positions and angles relative to the circumferen...

Embodiment 2

[0058] The specific preparation method of the tubular stent of this example is as follows:

[0059] Preparation steps of spinning solution: Gelatine has a relative molecular mass of about 50,000 and is dissolved in hexafluoroisopropanol at room temperature for about 12 hours to reach a final gelatine concentration of 8% (w / v). PLLA, number average molecular weight (Mn) of 420,000, was dissolved in a 50 / 50 (v / v) mixture of dimethylformamide and dichloromethane at room temperature for about 12 hours to achieve a 9% (w / v) Final PLLA concentration.

[0060] The gelatin layer of the tubular scaffold was prepared by the solution blow-spinning method: suck the dissolved gelatine solution with a 10 ml spinning syringe, fix the syringe in the precision syringe pump, set the feeding rate to 120 μL / min, press the air and gelatine solution The lines are all connected to the spray device, and the nozzle system can be placed at various positions and angles relative to the circumferential a...

Embodiment 3

[0063] The specific preparation method of the tubular stent of this example is as follows:

[0064] Preparation steps of spinning solution: Gelatine has a relative molecular mass of about 50,000 and is dissolved in hexafluoroisopropanol at room temperature for about 12 hours to reach a final gelatine concentration of 9% (w / v). PLLA, number average molecular weight (Mn) of 420,000, was dissolved in a 50 / 50 (v / v) mixture of dimethylformamide and dichloromethane at room temperature for about 12 hours to achieve a 10% (w / v) Final PLLA concentration.

[0065] The gelatin layer of the tubular scaffold was prepared by the solution blow-spinning method: suck the dissolved gelatine solution with a 10 ml spinning syringe, fix the syringe in the precision syringe pump, set the feeding rate to 120 μL / min, press the air and gelatine solution The lines are all connected to the spray device, and the nozzle system can be placed at various positions and angles relative to the circumferential ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com