Method for preparing products by corrugated board

A corrugated cardboard and product technology, applied in the field of corrugated cardboard production products, can solve problems such as inability to integrate, pollute the environment, and large randomness, and achieve the effect of strong integrity and good interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

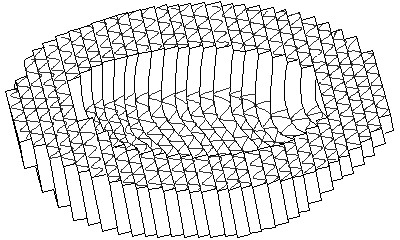

[0033] Please see first figure 1 , figure 1 It is the first embodiment of the three-dimensional structure of corrugated cardboard in the present invention, and it is also a paper fruit container. The bottom surface is a curved surface, and the middle is hollowed out for containing fruits, which belongs to the curved surface structure with complex space.

[0034] Because the paper fruit container is used to hold the fruit, it needs to bear a certain force, so the method includes the following steps:

[0035] ①Through the analysis of the force of the paper fruit container, determine the main force-bearing surface and auxiliary force-bearing surface of the product or product parts, and design the structure diagram of the prepared product and / or the structure diagram of the corresponding parts to ensure that the main force The direction of the corrugation inside the surface (regardless of size) is the same, and the direction of the corrugation is not parallel to the force-bearing...

Embodiment 2

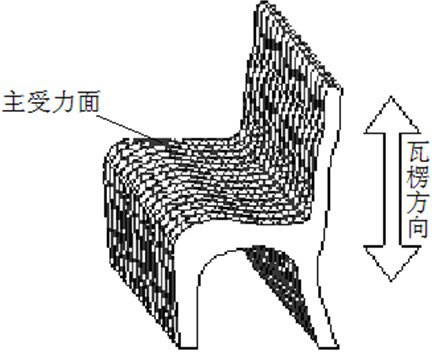

[0040] see image 3 , image 3 It is the second embodiment of the corrugated cardboard three-dimensional structure of the present invention, and it is also a paper chair, and its longitudinal section is " ” shape, which belongs to the open three-dimensional structure.

[0041] Since the paper chair needs to bear the weight of the human body, it is a product that needs to be subjected to strong or frequent forces, so the method includes the following steps:

[0042] ①Through the force analysis of the paper chair, determine the main force-bearing surface and auxiliary force-bearing surface of the product or product parts, and ensure the main force-bearing surface by designing the structure diagram of the prepared product and / or the corresponding parts structure The direction of corrugation in the surface (regardless of size) is the same, and the direction of the tile is not parallel to the force-bearing surface. Determine the corresponding position of the connecting positioni...

Embodiment 3

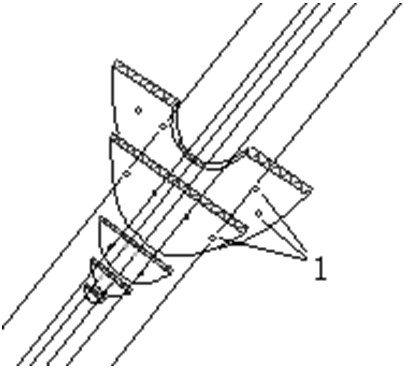

[0047] see Figure 5 , Figure 5 It is the third embodiment of the corrugated cardboard three-dimensional structure of the present invention, and it is also a small board made of paper, which belongs to the closed three-dimensional structure.

[0048] Since the paper board needs to bear the weight of the human body, it is a product that needs to be subjected to strong or frequent forces, so the method includes the following steps:

[0049] ①Through the force analysis of the paper small board, determine the main force-bearing surface and auxiliary force-bearing surface of the product or its parts, and ensure that the main The directions of the corrugations in the force-bearing surface (regardless of size) are the same, and the direction of the tiles is not parallel to the force-bearing surface. Determine the position of the corresponding connection positioning pin hole, see Figure 5 .

[0050] ②According to the component structure diagram, select the thickness of the corrug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com