Pavement construction method with inspection well

A construction method and inspection well technology, applied in the directions of roads, roads, artificial islands, etc., can solve the problems of the impact of the compaction work of large-scale rolling equipment, insufficient compaction of the inspection well filling materials, inconvenience in travel, and hidden safety hazards, etc. Improve the degree of compaction and support strength, reduce the degree of settlement, and reduce the effect of settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

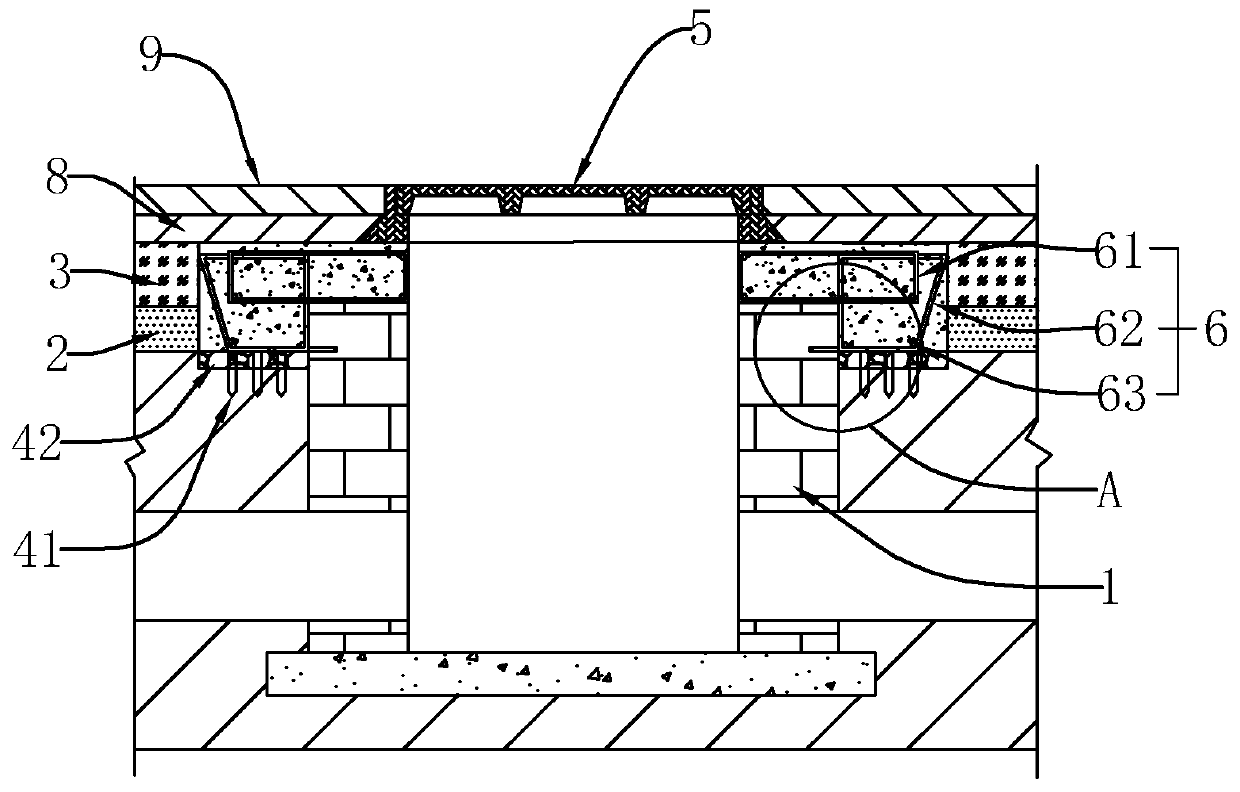

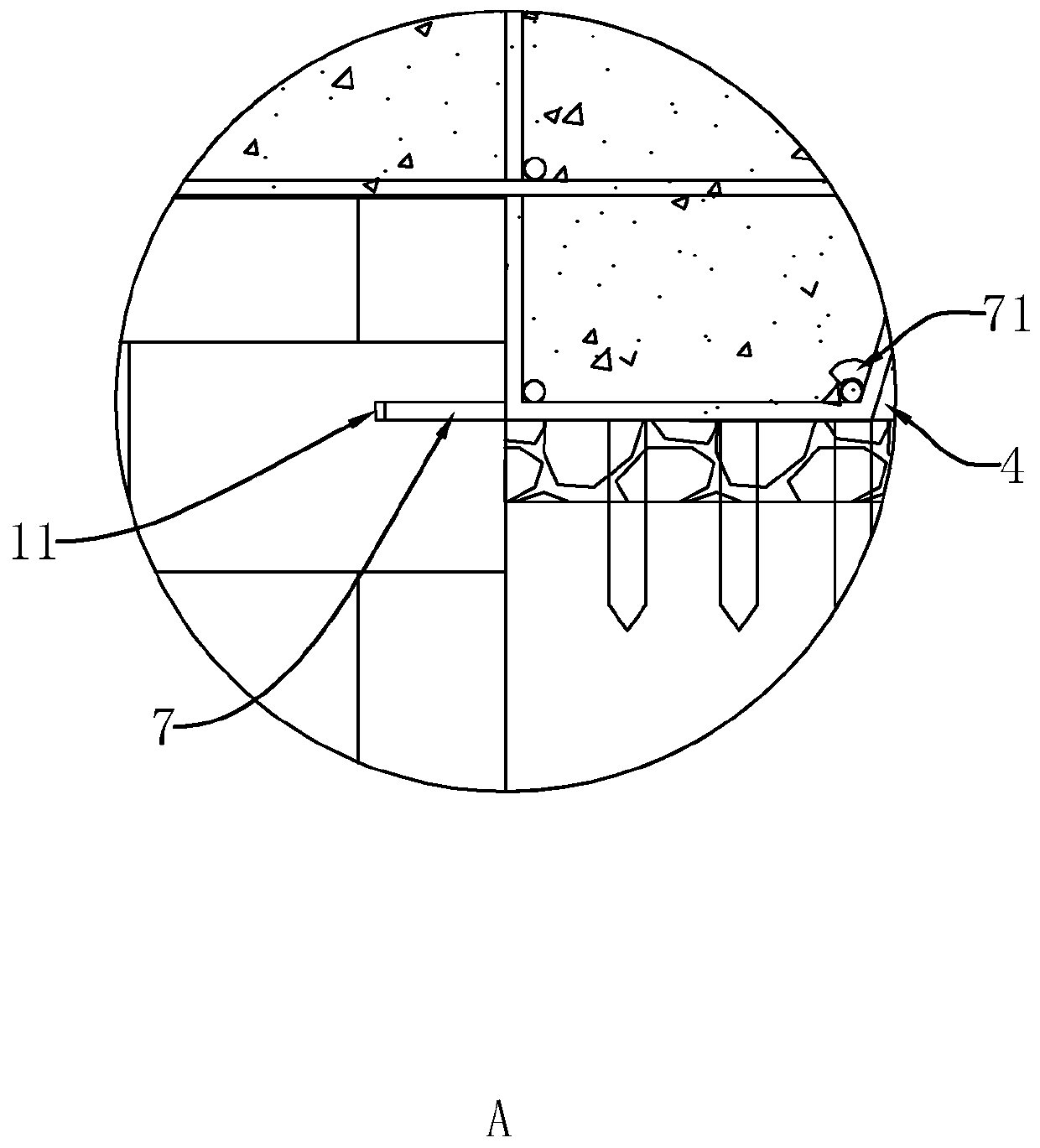

[0034] The present invention will be further described in detail below in conjunction with the drawings.

[0035] Reference figure 1 with figure 2 , The invention discloses a pavement construction method with inspection wells, including the following steps:

[0036] Step 1: According to the requirements of the design drawings, level the ground, excavate the trench on the site, lay a mortar leveling layer on the bottom of the trench, lay and install the pipeline on the leveling layer, backfill the pipeline with coarse sand, and then compact it , The density is more than 95%.

[0037] Step 2: Before masonry, water the bricks and moisten them, and then build the bottom foundation concrete in sequence, circle the well body 1, build the joint of the tube well and the inner and outer walls of the well, and check the opening and The gaps between the shaft walls are tightly sealed, and each layer of brick masonry is filled with cement.

[0038] Step 3: After the inspection well is built an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com