Vertical-shaft-type drilling technology for uranium mine in steeply-dipping and dewatered clastic rock formation and application

A vertical shaft, clastic rock technology, applied in the direction of drilling equipment, earthwork drilling, drilling equipment and methods, etc., can solve the problems of hole wall drop, difficult exploration work, mud leakage, etc., to achieve improved well deviation control, The effect of solving hole wall collapse and improving timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

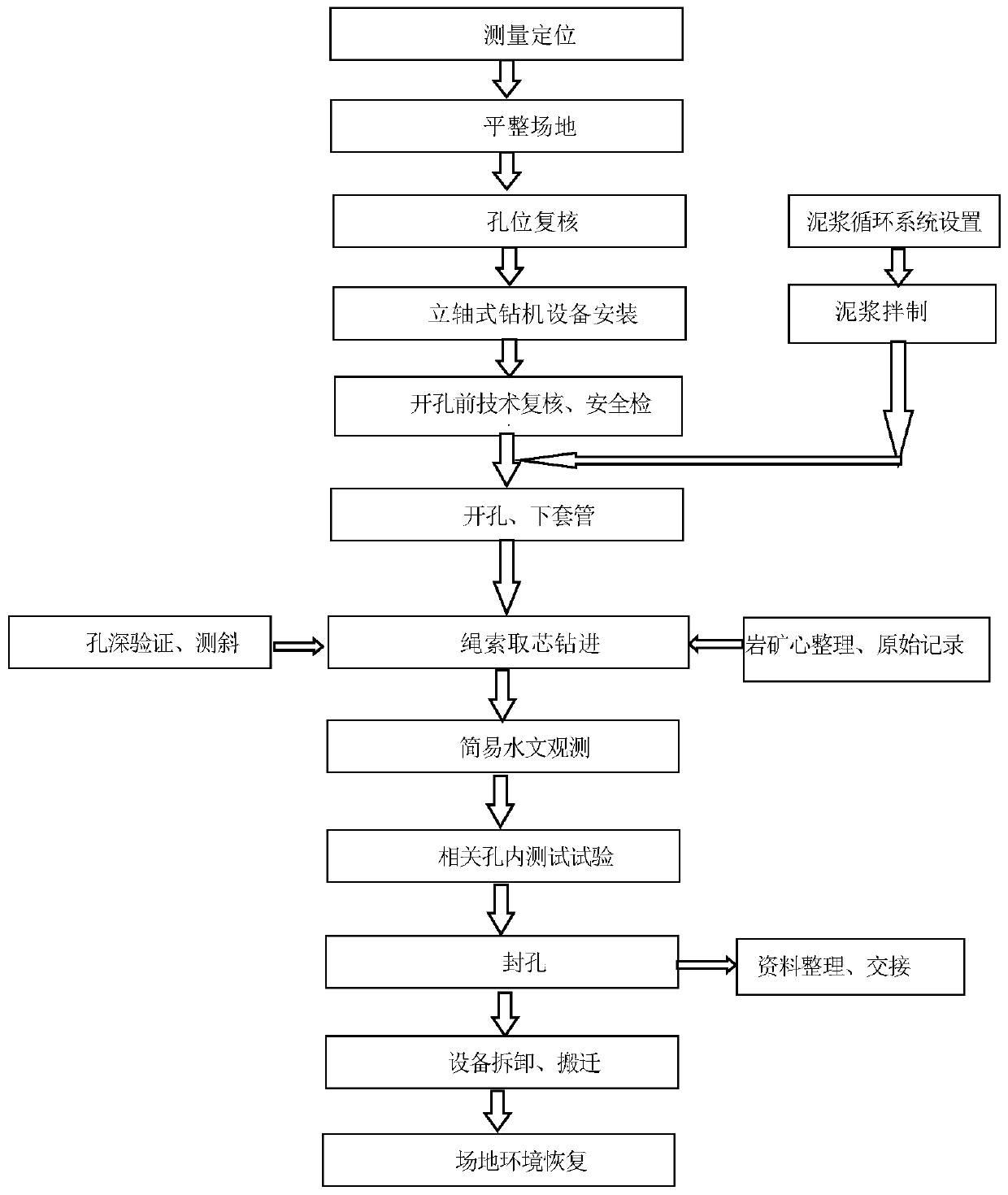

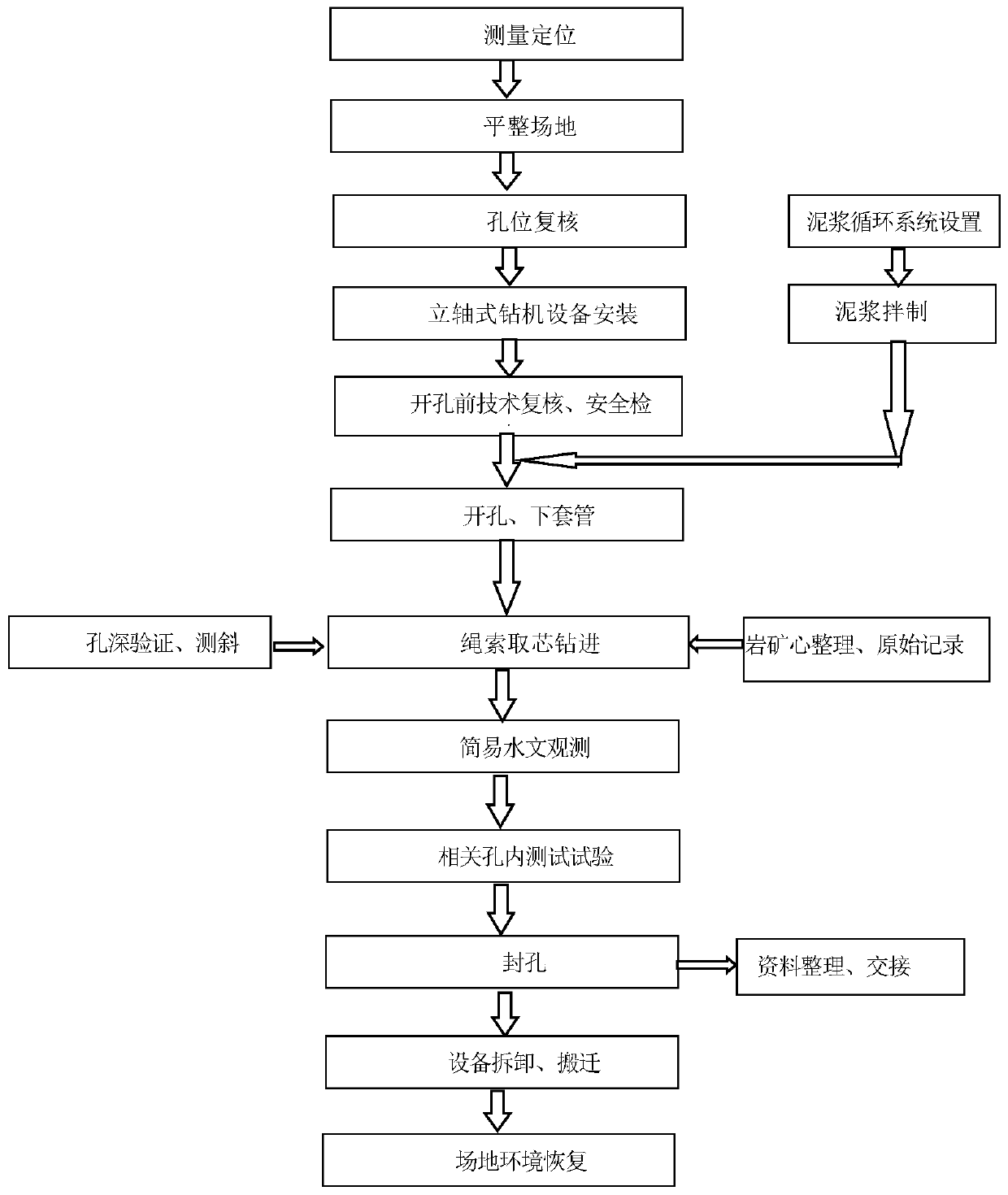

[0023] Below in conjunction with accompanying drawing, further describe the present invention through embodiment, but do not limit the scope of the present invention in any way.

[0024] The invention provides a new vertical-axis drilling technology in the exploration of uranium deposits in steep dry clastic rock formations. By using a vertical-axis drilling rig combined with a rope core drilling process, on this basis, it is feasible to combine drilling tools with drilling engineering parameters. With dynamic optimization, a set of practical drilling technology with stable drilling performance, strong operation controllability, greatly reduced drilling risk and greatly improved construction efficiency has been formed.

[0025] In the following examples, during the mechanical core drilling construction process, the appropriate drilling and mud parameters are used to solve the technical problems such as leaks, deviations, and collapsed holes during the drilling construction proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com