A method of manufacturing a cooler

A manufacturing method and cooler technology, which are used in semiconductor devices, electric solid-state devices, semiconductor/solid-state device parts, etc., can solve the problem of insufficient cleaning and drying of nickel-plated layer pollution, poor moisture in solder, poor soldering, etc. problems, to achieve the effect of increasing the lamination tightness, preventing relative stress, and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The "layer" mentioned in the present invention can be substrates such as boards and sheets. Lamination refers to thermocompression bonding or bonding. Alloying refers to the use of diffusion to form a diffusion alloy layer on the contact surface of two metals.

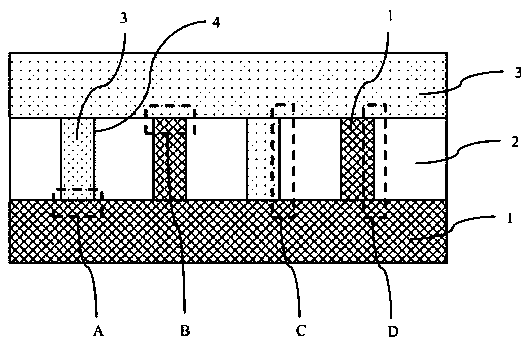

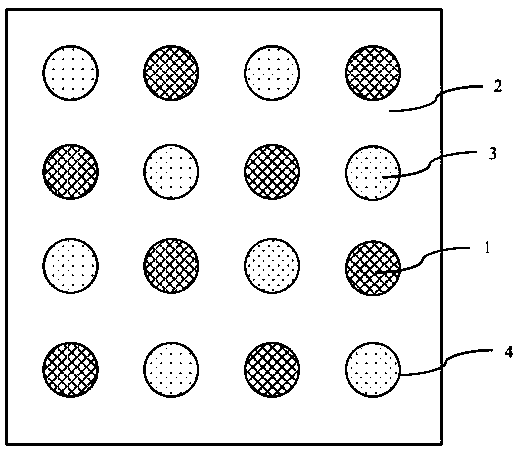

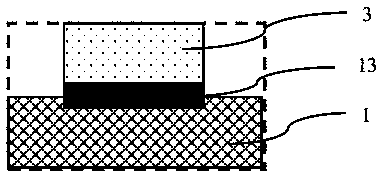

[0035] see figure 1 , the present invention provides a cooler, comprising: a laminated material that has a Ni layer 3, a Ti layer 2 and a Cu layer 1 sequentially bonded and integrated into a laminated shape, and the Ni layer 3 has a function for making the object to be cooled The upper surface joined by soldering is made of Ni or a Ni alloy, the Ti layer 2 is arranged on the lower surface side of the Ni layer 3 and is made of Ti or a Ti alloy, and the Cu layer 1 is arranged on the The lower surface side of the Ti layer 2 is composed of Cu or Cu alloy, and the cooler makes the lower surface of the Cu layer 1 of the laminated material and the cooling surface of the cooler main body bonded via a brazing material la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com