Shoelace threading cap type overlying strata separation layer grouting settlement reduction method

A technology of overburden separation and shoelace wearing, which is applied in the field of grouting and settlement of shoelace cap type overburden separation, and can solve the problems of low injection-production ratio, no consideration of overlying rock and surface lag subsidence, grouting Short duration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

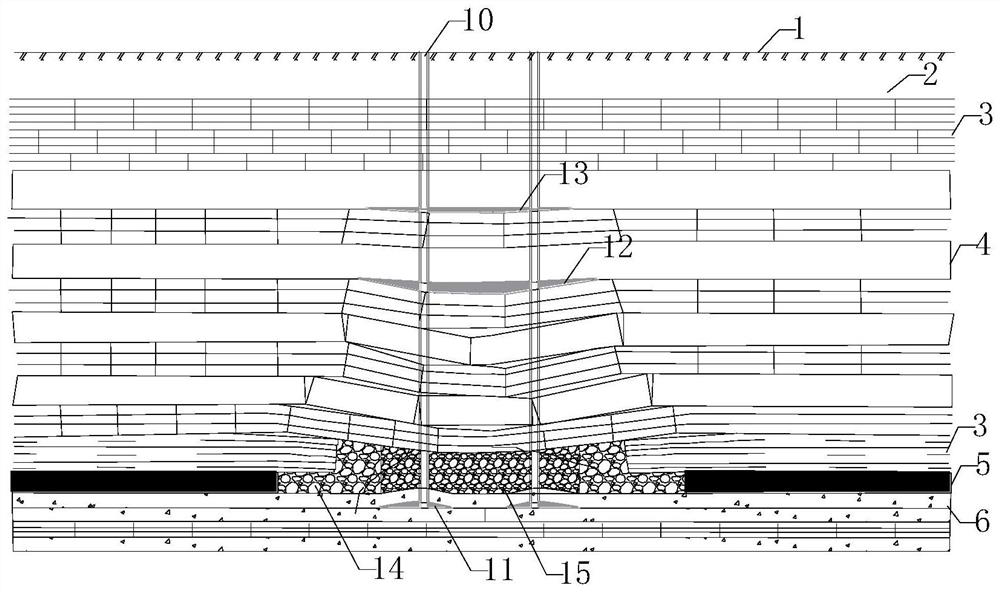

[0024] The technical solutions of the present invention will be described in more detail below in combination with the accompanying drawings in the embodiments of the present invention.

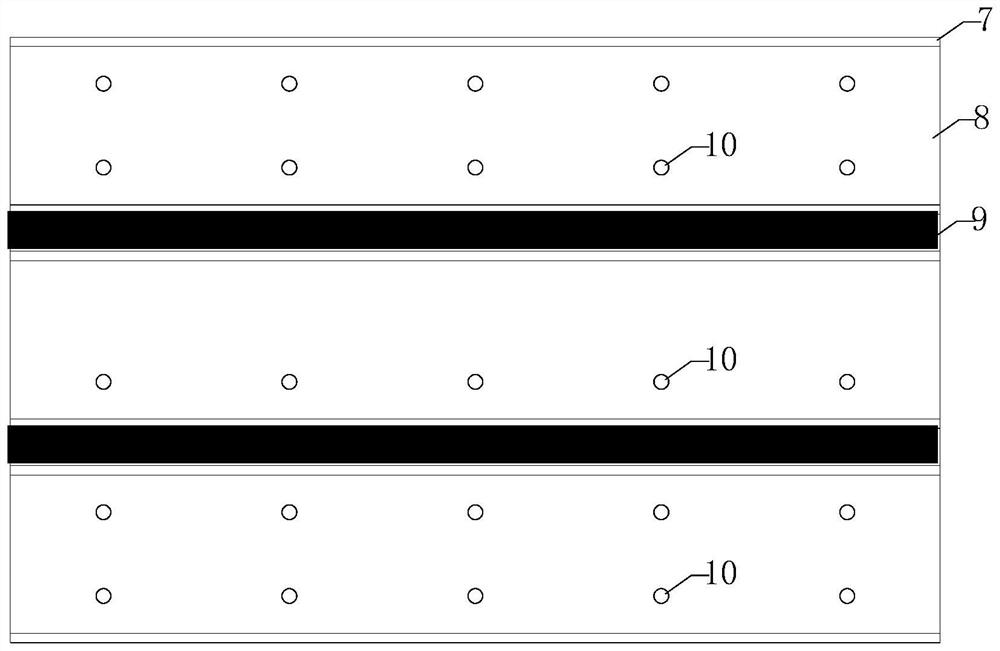

[0025] like Figure 1-2 As shown, a method for grouting and subsidence reduction of the overlying strata detachment layer with shoelaces and caps comprises the following steps:

[0026] Step1: Obtain the columnar shape of the drill hole, and use the key layer theory to determine the position of the key layer 4 in the overlying rock. The key layer has a large thickness and strength, which is different from the common rock layer 3 (usually mudstone and siltstone) between the key layer 4; The separation layer is generated in the lower part of the bottom surface of the key layer. It is determined that the main grouting layer 12 for the separation layer grouting is located at the lower part of the bottom of the first key layer 120m above the upper part of the coal seam 5, and the secondary groutin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com