Gravity center adjustable loading machine applied to complex working condition

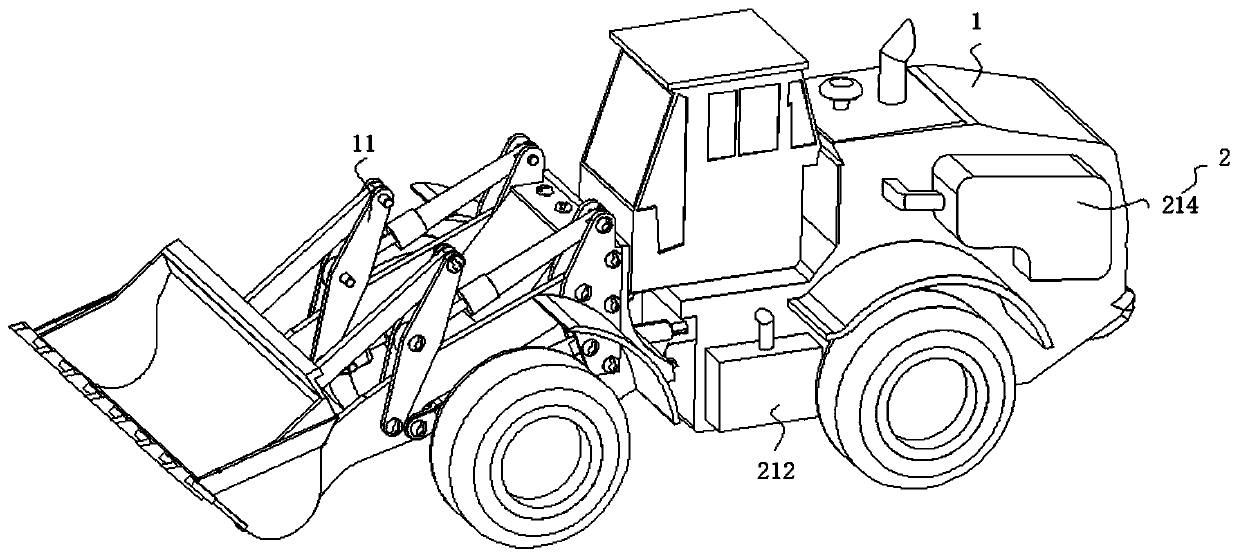

A technology for complex working conditions and loaders, which is applied to earth movers/excavators, construction, etc. It can solve problems such as large climbing angle, heavy impact and noise of counterweight, failure to construct or roll over, etc., to improve driving Effect of stability, impact and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

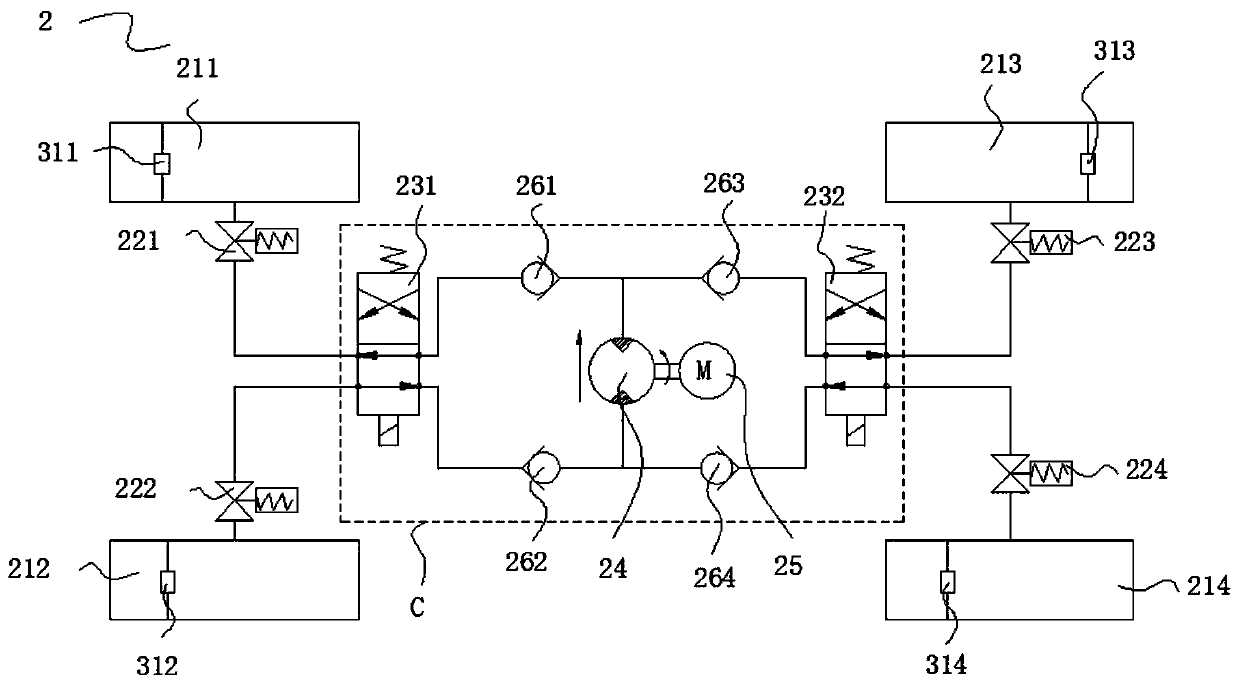

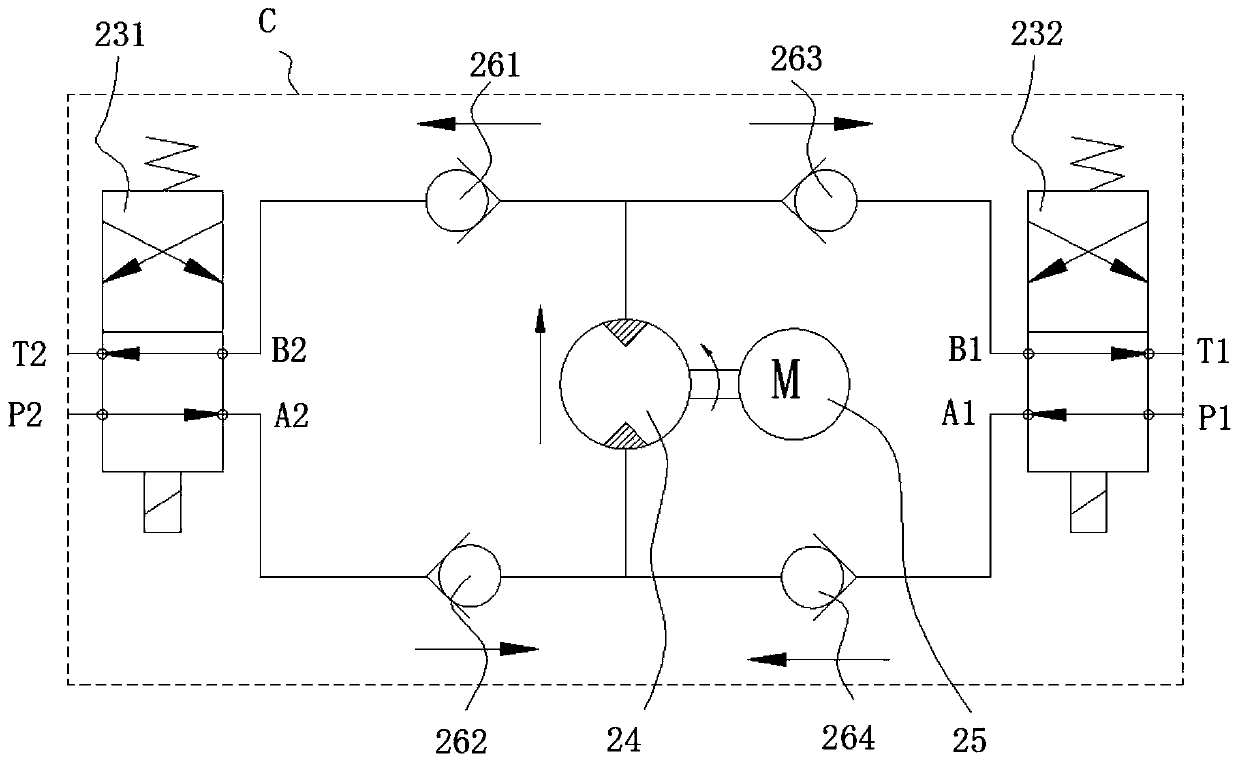

Method used

Image

Examples

Embodiment

[0030] Embodiment: When using the loader, connect the power supply of each sensor and chip in the fluid counterweight system 2 and the counterweight electronic control system 3, and the output terminals of the force sensor 33 and the slope sensor 32 are all electrically connected with the integrated drive chip 34 , the force sensor 33 is used to measure the weight of the load in the bucket 111, and transmits the load information of the bucket 111 to the integrated driver chip 34, as in Figure 4 The load of the internal measuring bucket 111 is m5g, and the slope sensor 32 is installed in the central channel at the bottom of the cockpit of the loader body 1. During installation, its direction must be consistent with the positive direction of the vehicle coordinates, and it is used to measure the gap between the slope surface and the horizontal surface. angle, as in Figure 4 The internally measured front and rear inclination angle is α, in Figure 5 The left and right inclinatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com