Arc-triangle-shaped powder metallurgy brake pad for high-speed motor train unit

A high-speed EMU, powder metallurgy technology, applied in the direction of friction lining, brake type, brake components, etc., can solve the problems of large temperature difference of friction body, accelerated thermal recession, affecting friction performance of friction block, etc. The effect of uniform difference, reducing braking temperature and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

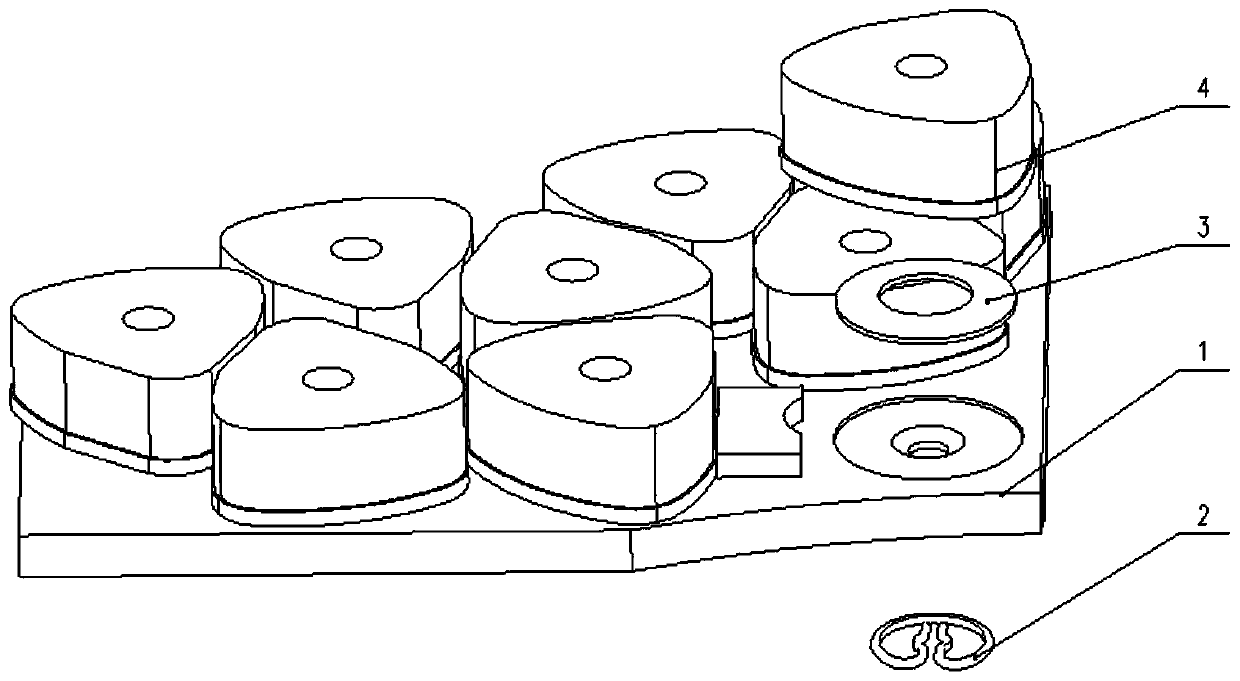

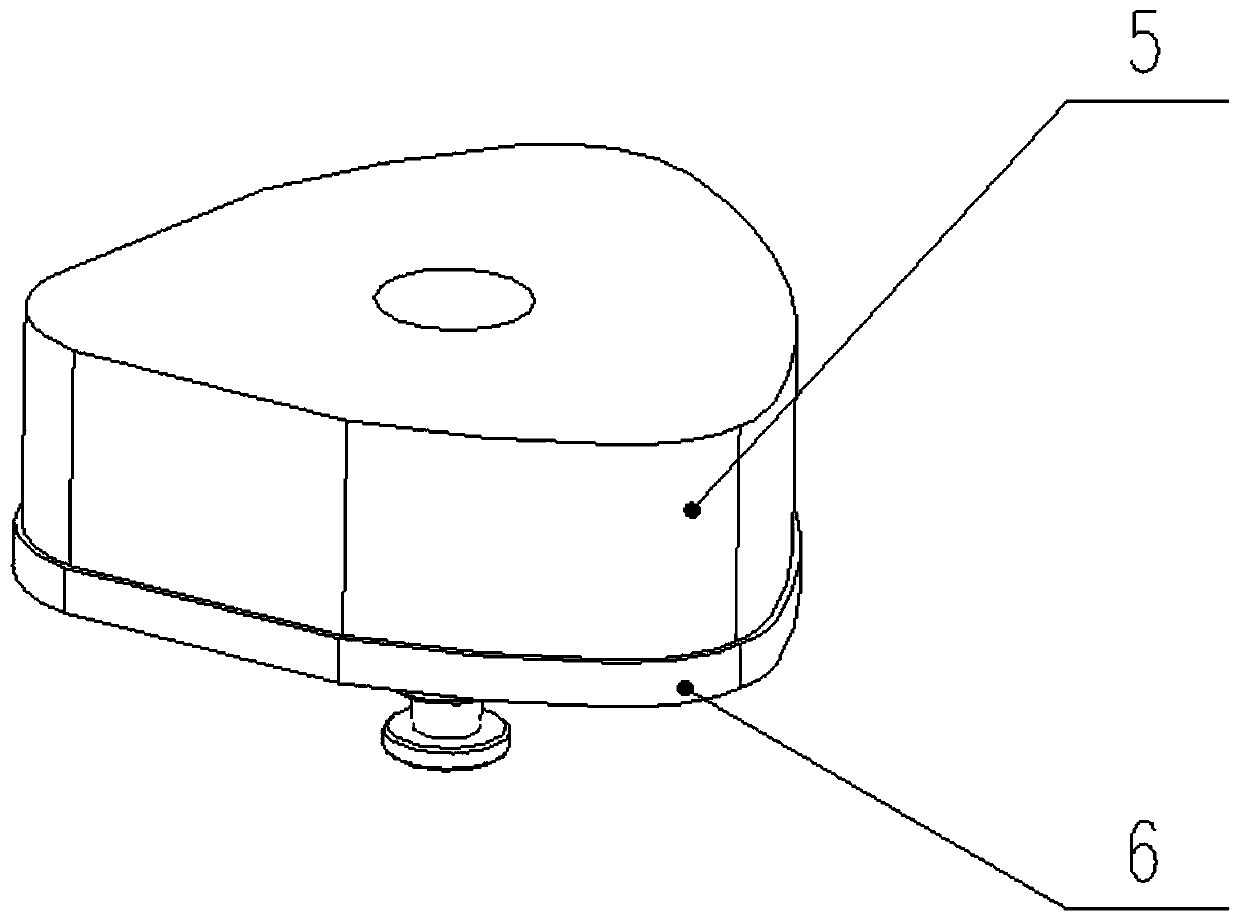

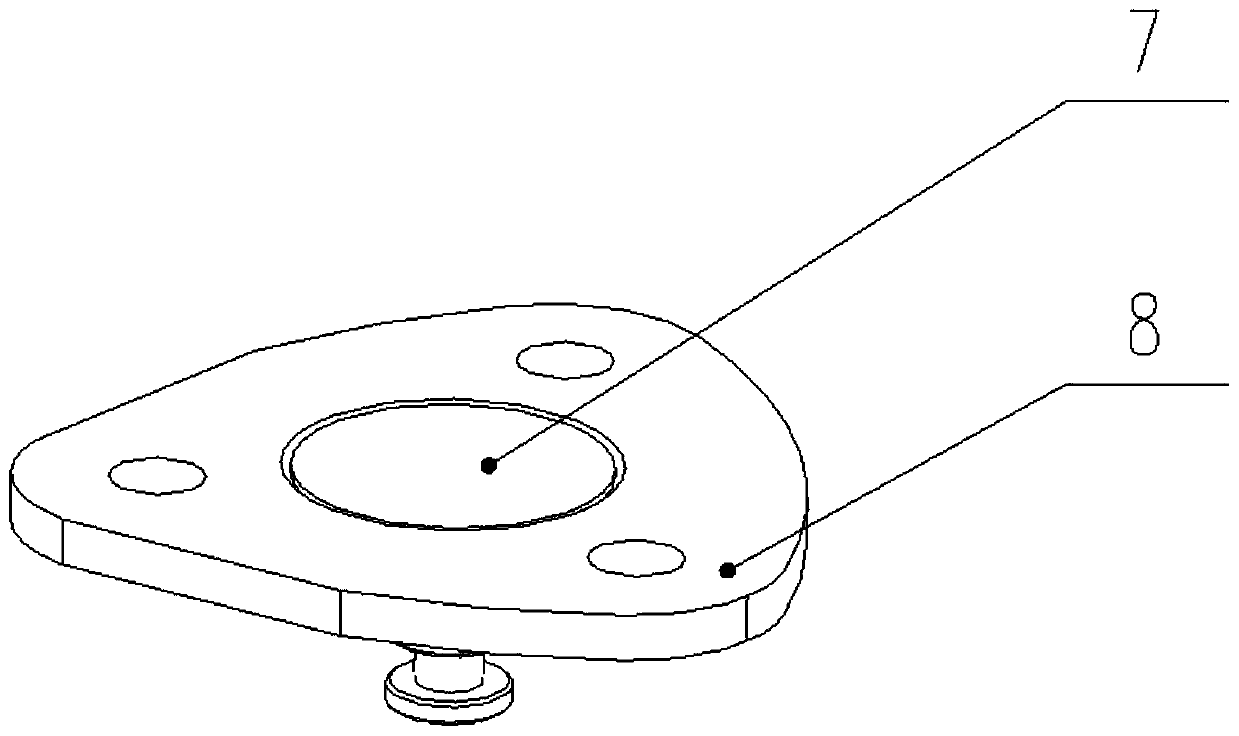

[0035] A powder metallurgy brake pad for high-speed EMUs in an arc-triangular shape, such as Figure 1 to Figure 8 As shown, it includes: steel back 1, circlip 2, disc spring 3, friction block 4, friction body 5, base 6, positioning pin 7, skeleton 8, circlip mounting hole 9, disc spring mounting hole 10, anti Rotation boss 11, anti-rotation boss 12, round hole 13, circlip groove 14, spherical surface 15, etc. in:

[0036] Such as figure 1 As shown, the powder metallurgy brake pad for high-speed trains of the present invention is composed of a steel back 1, a plurality of circlips 2, a plurality of disc springs 3 and a plurality of friction blocks 4.

[0037] Such as Figure 4 and Figure 5 As shown, the steel back 1 is provided with a circlip mounting hole 9 , a disc spring mounting hole 10 , an anti-rotation boss 11 , and an anti-rotation boss 12 . The disc spring mounting hole 10 is a circular counterbore with a depth of 1mm-2mm, which is set on the side of the steel b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com