Liquid-liquid separation device and method for liquid methionine production

A liquid methionine and liquid separation technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of difficult drying, difficult separation, back-mixing, etc., to improve the separation purity and separation efficiency, simplify the operation process, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

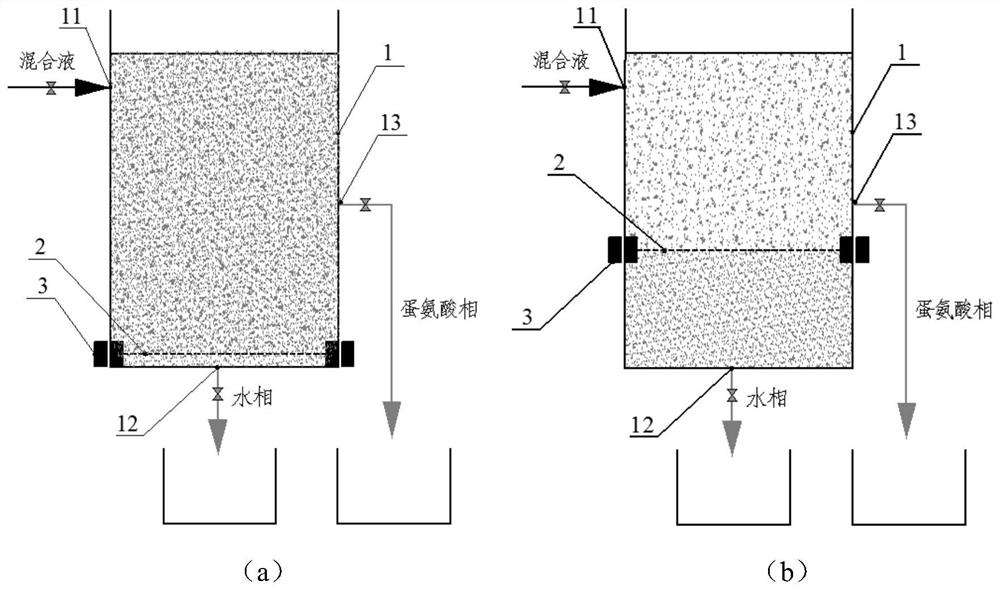

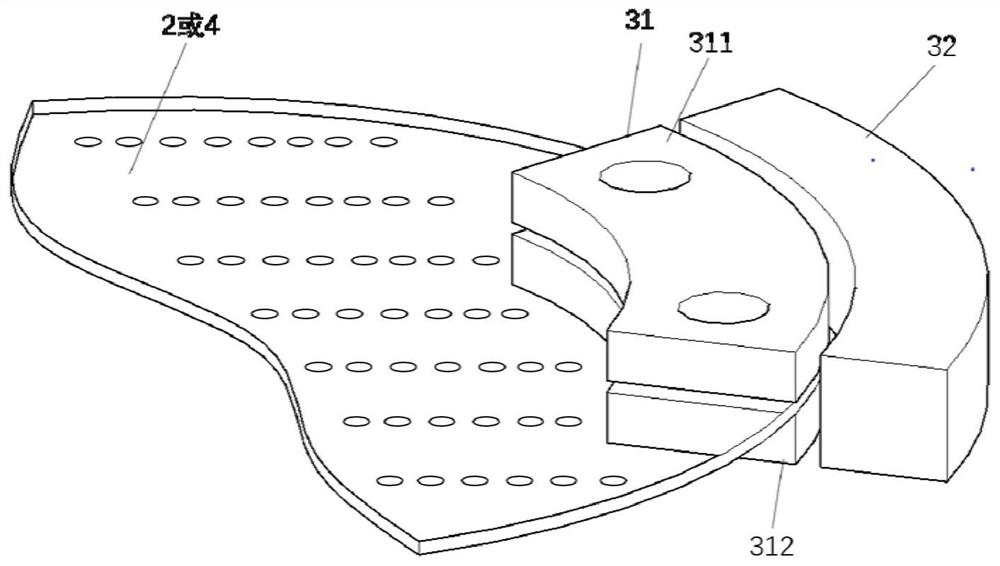

[0039] The liquid-liquid separation device used in the production of liquid methionine provided by this embodiment has a structure such as figure 1 As shown, it includes a separation container 1, an ultra-hydrophilic filter screen 2 and a mobile fixture 3. The ultra-hydrophilic filter screen 2 is installed and positioned in the separation container 1 through a movable fixture.

[0040] In this embodiment, the separation container is a cylindrical structure with a closed bottom. Such as figure 1 As shown, the separation container 1 is designed with a mixed liquid inlet 11, an aqueous phase outlet 12 and a liquid methionine phase outlet 13, the aqueous phase outlet 12 is set at the bottom of the separation container, and the mixed liquid inlet 11 and the liquid methionine phase outlet 12 are set at the separation container On the two opposite sides, the position of the mixed solution inlet 11 and the liquid methionine phase outlet 13 on the separation container is higher than ...

Embodiment 2

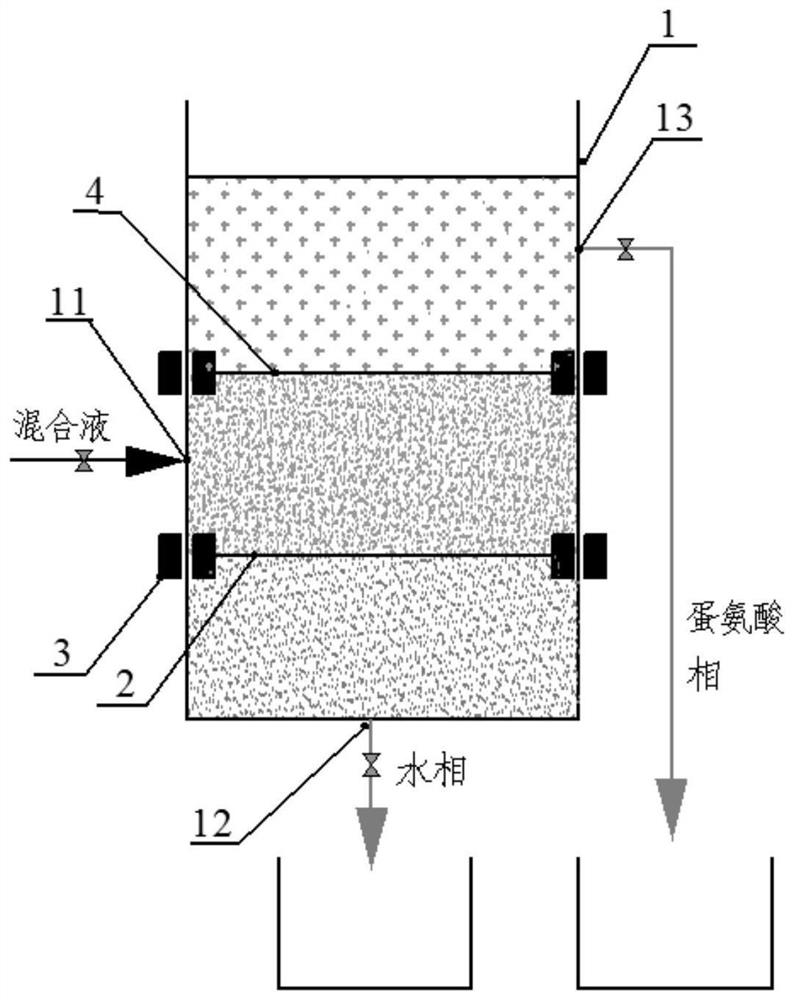

[0052] The liquid-liquid separation device used in the production of liquid methionine provided by this embodiment has a structure such as image 3 As shown, it includes a separation container 1, an ultra-hydrophilic filter screen 2, an ultra-hydrophobic filter screen 4 and a mobile fixture 3. Both the ultra-hydrophilic filter screen 2 and the super-hydrophobic filter screen 4 are installed in the separation container 1 through movable fixtures, and the super-hydrophobic filter screen 4 is located on the super-hydrophilic filter screen 2 with a gap between them.

[0053] In this embodiment, the separation container is a cylindrical structure with a closed bottom. Such as image 3 As shown, the separation container 1 is designed with a mixed solution inlet 11, an aqueous phase outlet 12 and a liquid methionine phase outlet 13, and valves are provided on the mixed solution inlet 11, the aqueous phase outlet 12 and the liquid methionine phase outlet 13. The position of the mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com