Two-piston and four-chamber supercharged tool release oil cylinder

A technology of loosening the knife and oil cylinder, applied in the direction of clamping, supporting, positioning devices, etc., which can solve the problems of small thrust and unsuitable for large-scale machining centers, and achieve the effect of large thrust and small overcoming thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

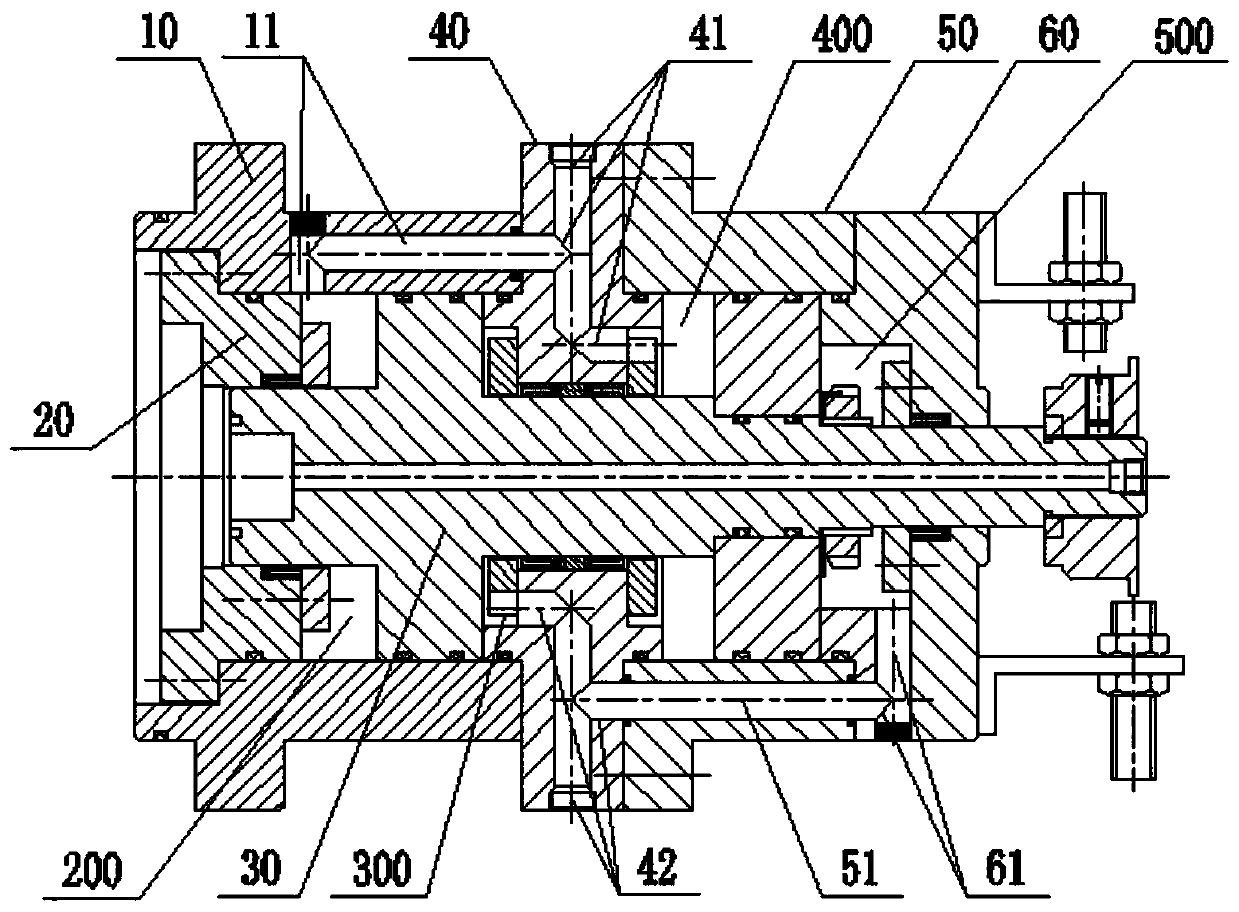

[0044] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 Shown; A kind of two-plug four-chamber supercharged loose knife oil cylinder, comprises:

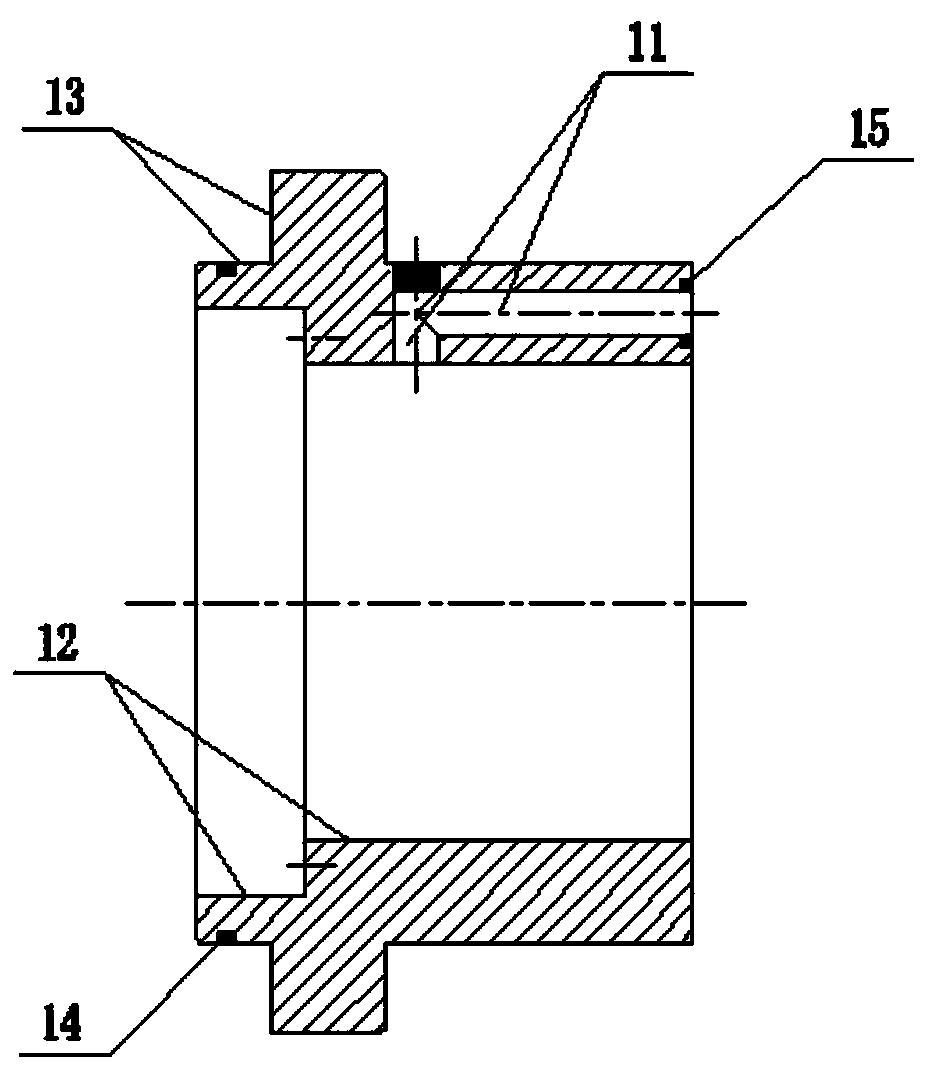

[0045] A first shell member 10, connected to the main shaft 1000, has a first oil passage 11 on the side wall;

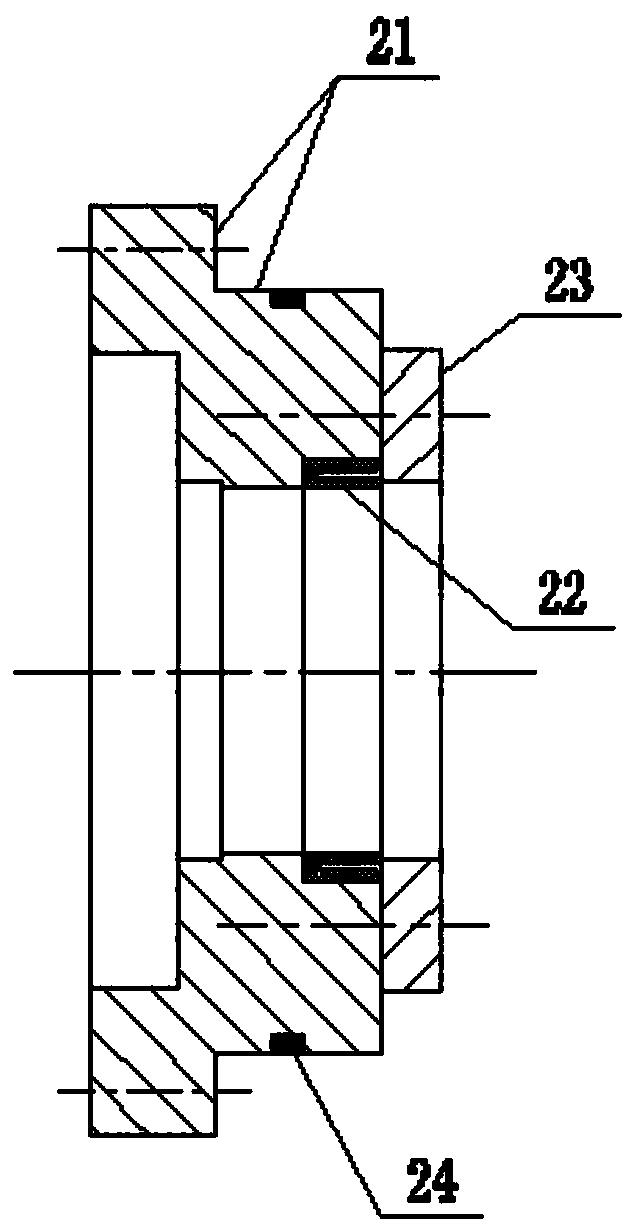

[0046] a first stopper 20, fitted in the first housing member 10, and close to the main shaft 1000;

[0047]A piston member 30, one end of which is matched with the inner wall of the first housing member 10, and can pass through the first stopper 20, and move back and forth along the first housing member 10 and the first stopper 20 , forming a first cavity 200 between the first housing member 10 and the first stopper 20; the first cavity 200 communicates with the first oil passage 11;

[0048] A barrier member 40 has a second oil channel 41 and a third oil channel 42 on the side wall, sleeved on the piston member 30 and connected with the first housing member 10, and...

Embodiment 2

[0102] like figure 1 , Figure 4 , Figure 8 As shown; on the basis of Embodiment 1, the central part of the piston member 30 is also provided with a stepped through hole 37;

[0103] The stepped through hole 37 includes an internally threaded hole for connecting a connecting pipe with an external thread; a long through hole connected to the internally threaded hole; and a short through hole connected to the long through hole; The inner diameter of the short through hole is more than twice the inner diameter of the long through hole, which can gather more air;

[0104] During implementation, through connecting pipes with external threads, connecting hoses, passing air into the stepped through hole 37, the circulating air can take away heat, thereby reducing the pressure on the two-plug four-chamber pressurized loosening cylinder and the main shaft. The temperature has the effect of cooling down;

Embodiment 3

[0106] like figure 1 , Figure 8 As shown; on the basis of the second embodiment, a contact piece 38 is also provided on the end of the piston member 30; a first non-contact switch 39 and a second non-contact switch 39 are also provided on the side wall of the second stopper 60 Non-contact switches 391 are respectively used to cooperate with the contacts 38;

[0107] During implementation, the contact piece 38 includes a shaft sleeve, which is threaded on the external thread section at one end of the stepped shaft 31; The non-contact switch 39 and the second non-contact switch 391 are used;

[0108] The first non-contact switch 39 and the second non-contact switch 391 are structures in the prior art, such as KZ-H360ZF type; the distance from the second non-contact switch 391 to the side wall of the second stopper 60 , greater than the distance from the first non-contact switch 39 to the side wall of the second stopper 60;

[0109] When the annular flange on the contact pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com