Fully automatic logistics packaging robot

A fully automatic and robotic technology, applied in the mechanical field of packaging objects or materials, can solve the problems of low packaging efficiency of candies, achieve the effects of improving packaging efficiency, strengthening the limit effect, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

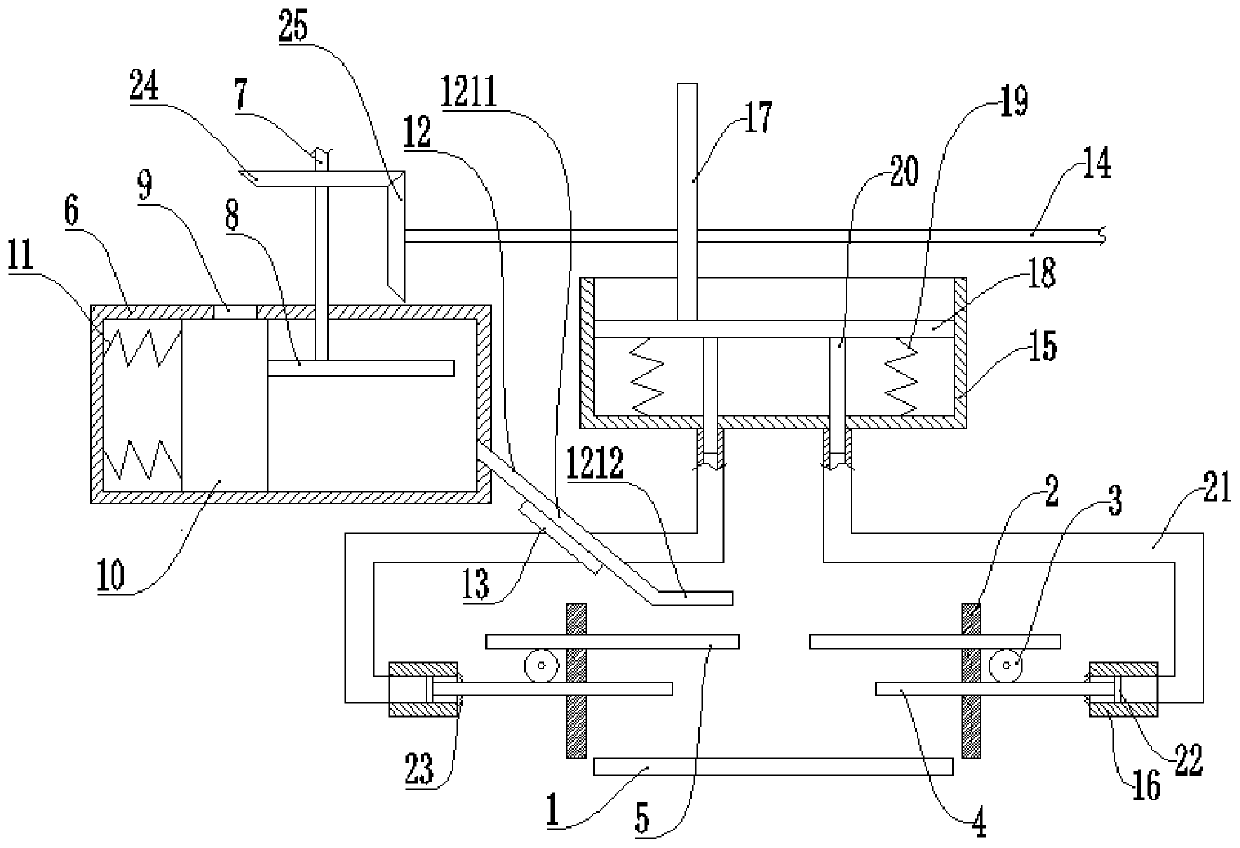

[0025] Basic as attached figure 1 Shown: a fully automatic logistics packaging robot, including a base on which a conveyor belt 1, a quantitative feeding mechanism and a packaging mechanism are installed, and the quantitative feeding mechanism is set toward the direction of the conveyor belt 1; the conveyor belt 1 in this embodiment is a belt commonly used in the market type conveyor, so I won’t go into details.

[0026] The quantitative feeding mechanism comprises a motor and a material box 6 welded on the support, the output shaft of the motor is welded with a vertical shaft 7 passing through the material box 6, and the vertical shaft 7 is sleeved with a cam-8; the material box 6 There is a feed inlet 9 on the top, and a slide block 10 is slidably connected to the cam-8 in the material box 6, and a spring-11 is fixedly connected between the slide block 10 and the material box 6, and the feed port 9 is located on the slide block 10. The bottom of the material box 6 is connec...

Embodiment 2

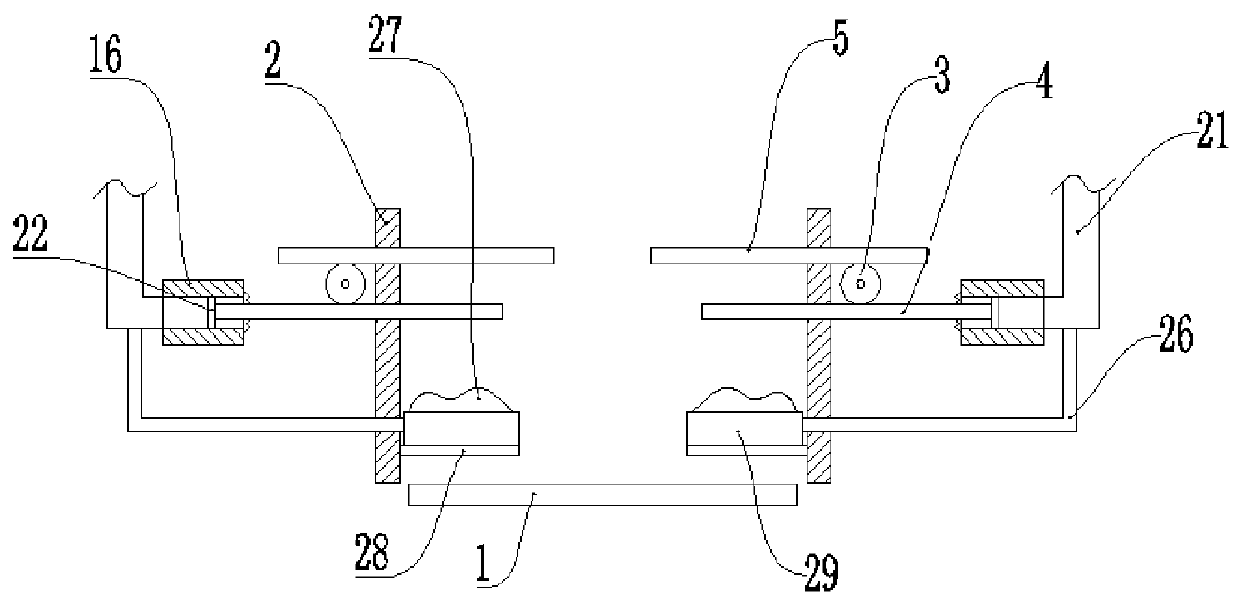

[0036] Basic as attached figure 2 As shown, the structure and implementation of Embodiment 2 are basically the same as Embodiment 1, the difference is that: the side pipe 26 passing through the fixing plate 2 is connected to the pipe 21, and the end of the side pipe 26 away from the pipe 21 is fixedly connected There is an air bag 27; the diameter of the side pipe 26 is smaller than that of the pipe 21. A side plate 28 is welded to the side of the fixed plate 2 close to the conveyor belt, and the side plate 28 is located below the airbag 27 ; a baffle plate 29 is welded on the side plate 28 .

[0037] The specific implementation process is as follows:

[0038] In use, when the lifting plate 18 moves downward, the vertical block 20 also moves downward; the vertical block 20 moves downward in the pipe 21, so that a part of the gas in the pipe 21 enters the cylinder 16, and another part of the gas enters the side In the pipe 26; because the diameter of the side pipe 26 is smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com