Novel semi-coke gasifier device

A gasifier and blue carbon technology, which is applied in the field of new blue carbon gasifier devices, can solve the problems of reducing gasification efficiency and blue carbon gasification rate, reducing the life of the grate, easily causing partial burning, etc. The effect of carbon utilization rate, improving service life and ensuring gas calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

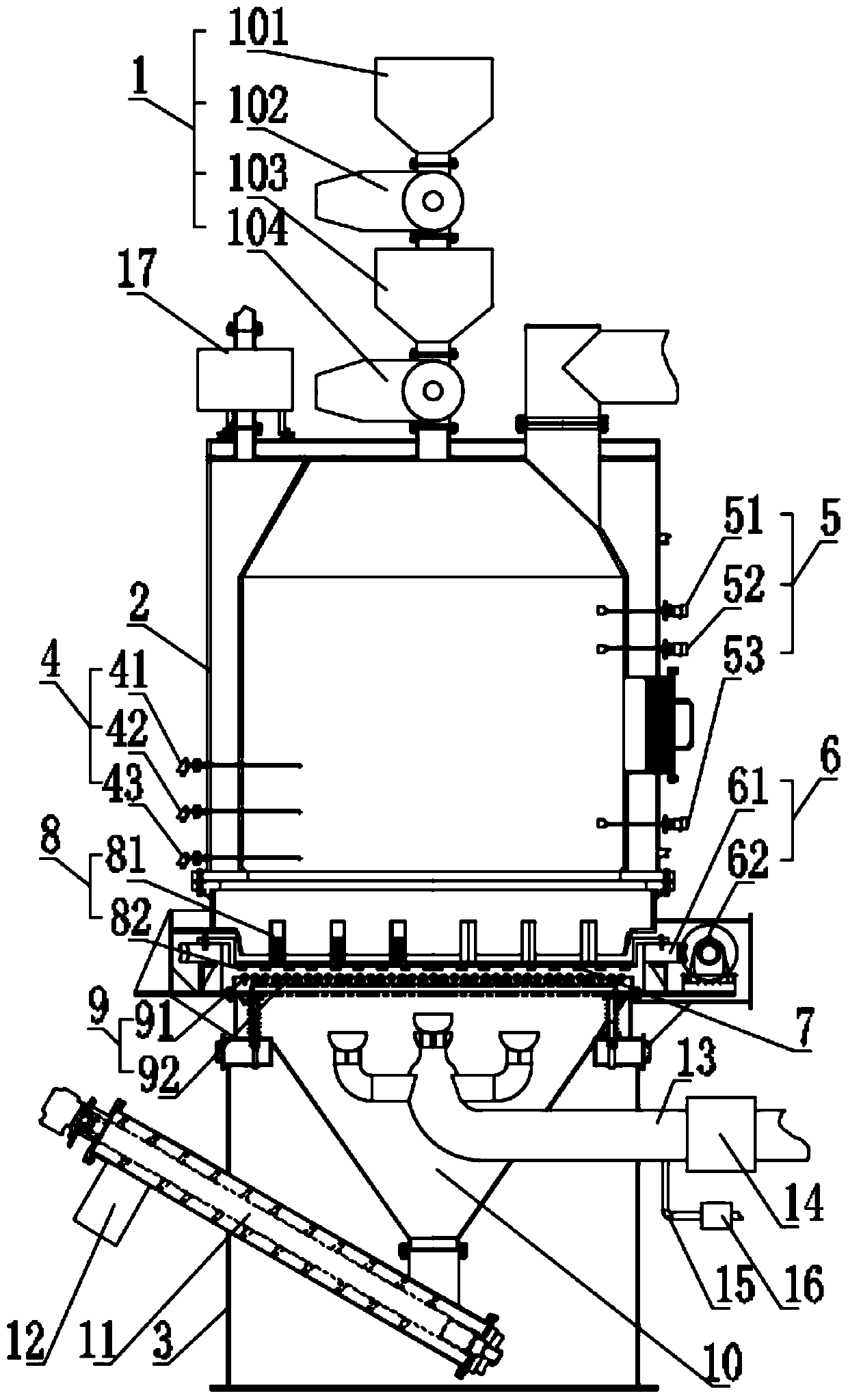

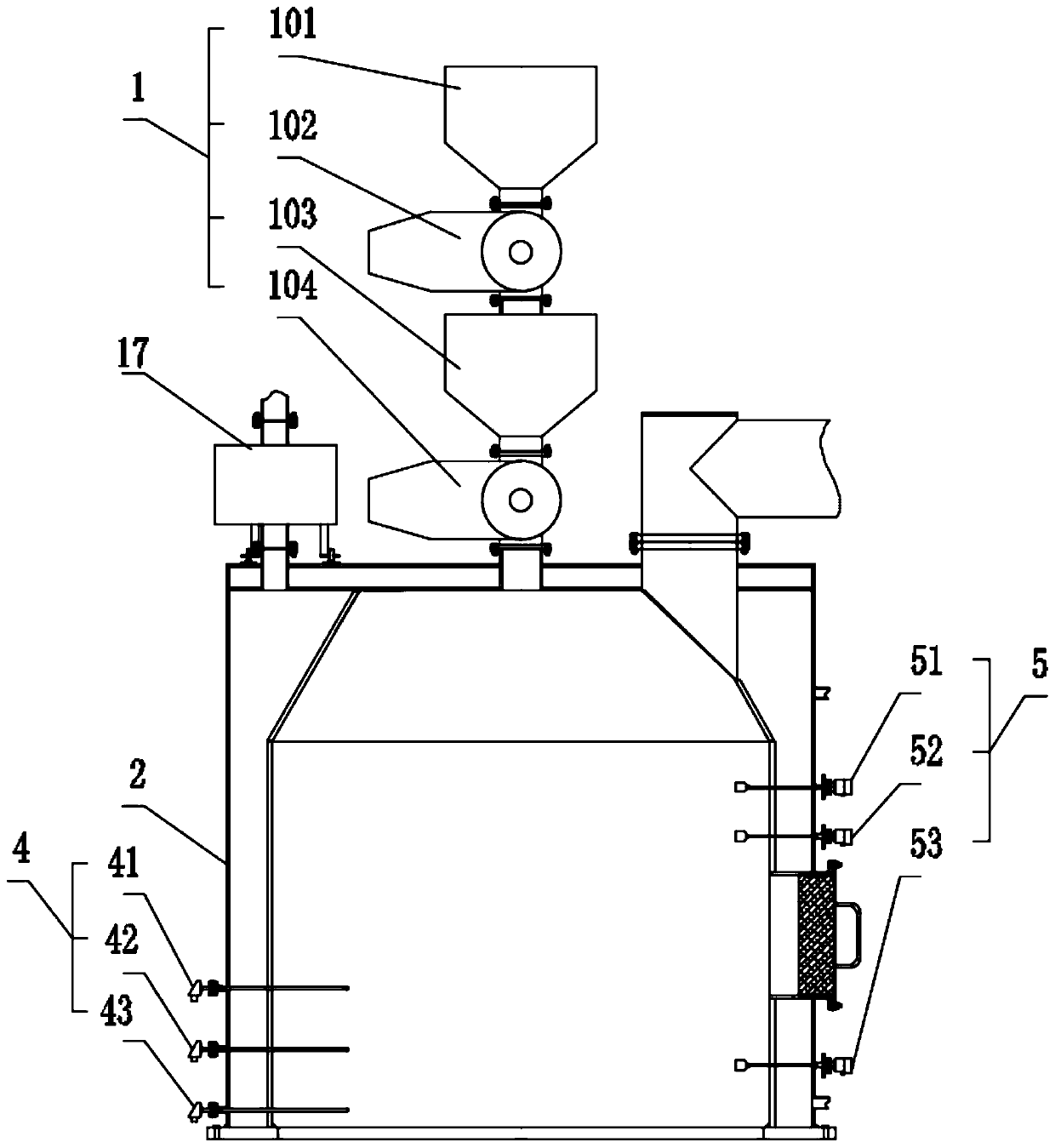

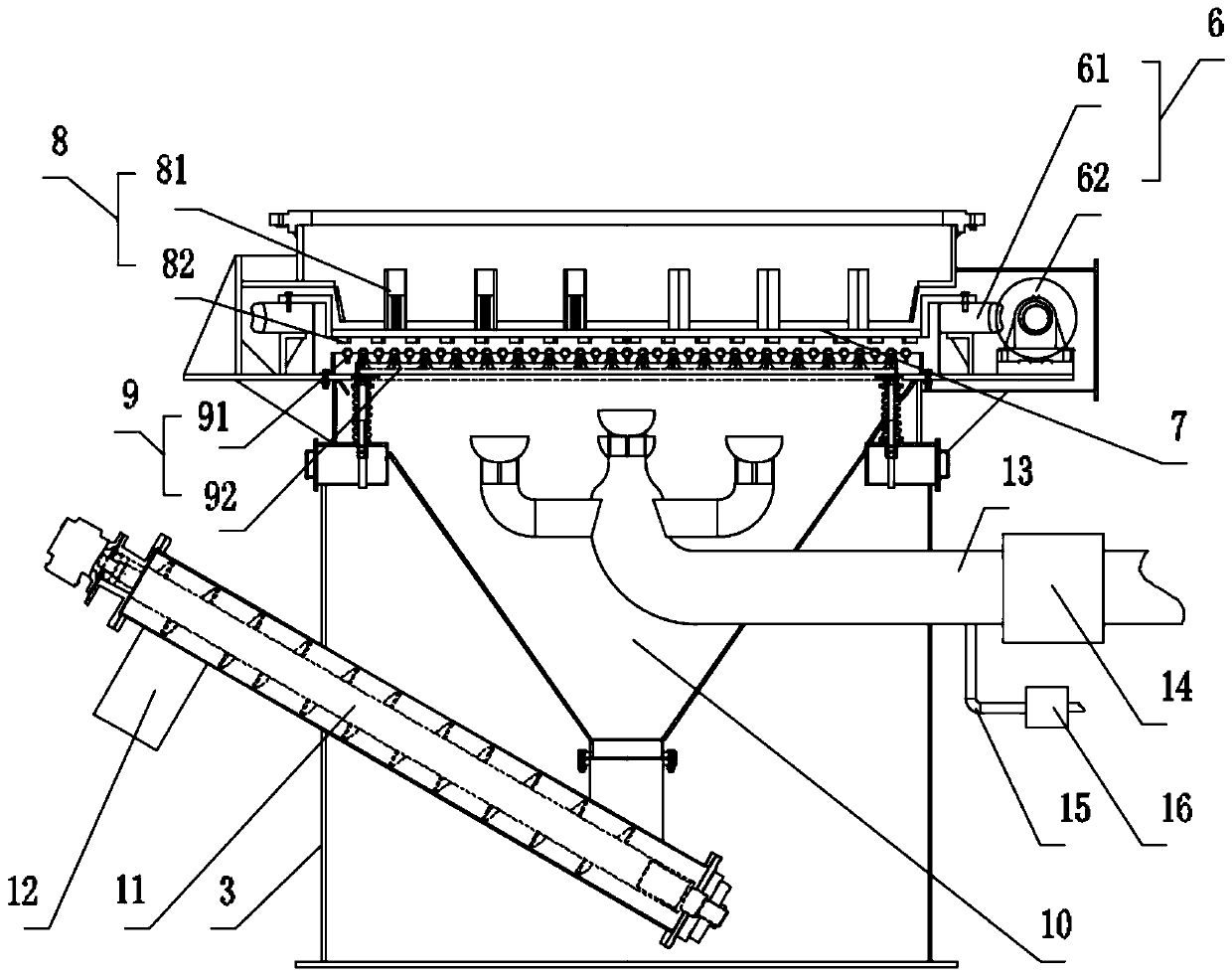

[0022] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0023] A new type of semi-coke gasification furnace device, including an upper furnace body 2 and a lower furnace body 3, the upper furnace body 2 and the lower furnace body 3 are clamped and connected by flanges, and a connected cutting material is provided above the upper furnace body 2 The device 1 and the steam-water separator 17 are provided with a temperature sensor 4 and a coal level detector 5 inside, and the temperature sensor 4 and the coal level detector 5 are respectively connected to the control center 18, and the inside of the lower furnace body 3 is arranged sequentially from top to bottom. There are a slag breaking device 8, a grate device 9, a slag storage bin 10 and a screw conveyor 11. The slag bre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com