Short pier rigid-frame bridge pier bottom structure with function of greatly reducing bearing bending moment

A large-scale, rigid-frame bridge technology, used in bridges, bridge construction, bridge parts, etc., can solve the problems of affecting structural durability, large bending moment at the bottom of piers, cracking of bridge piers, etc., to ensure safety, durability and quality. Guaranteed reliability, release shrinkage and creep effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

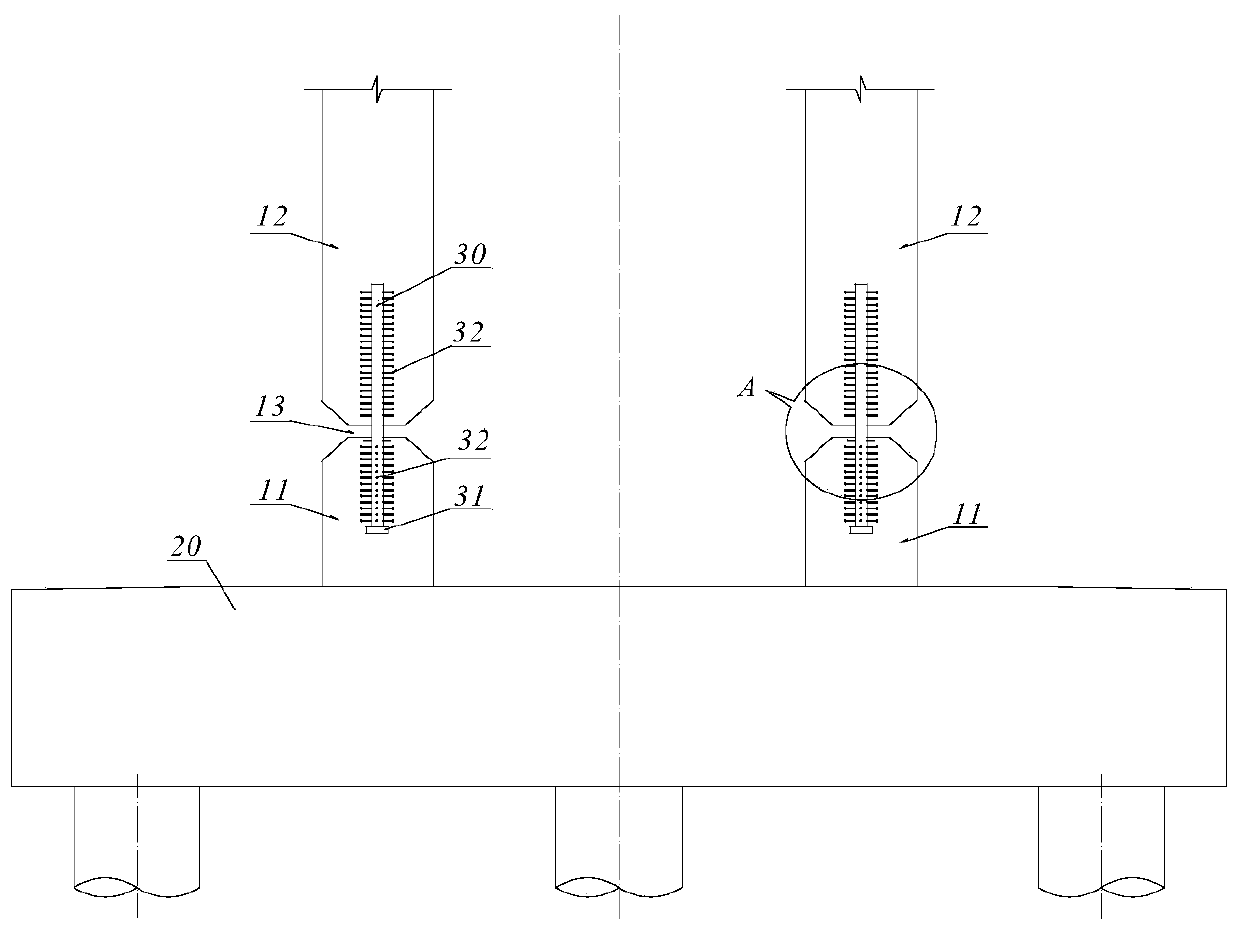

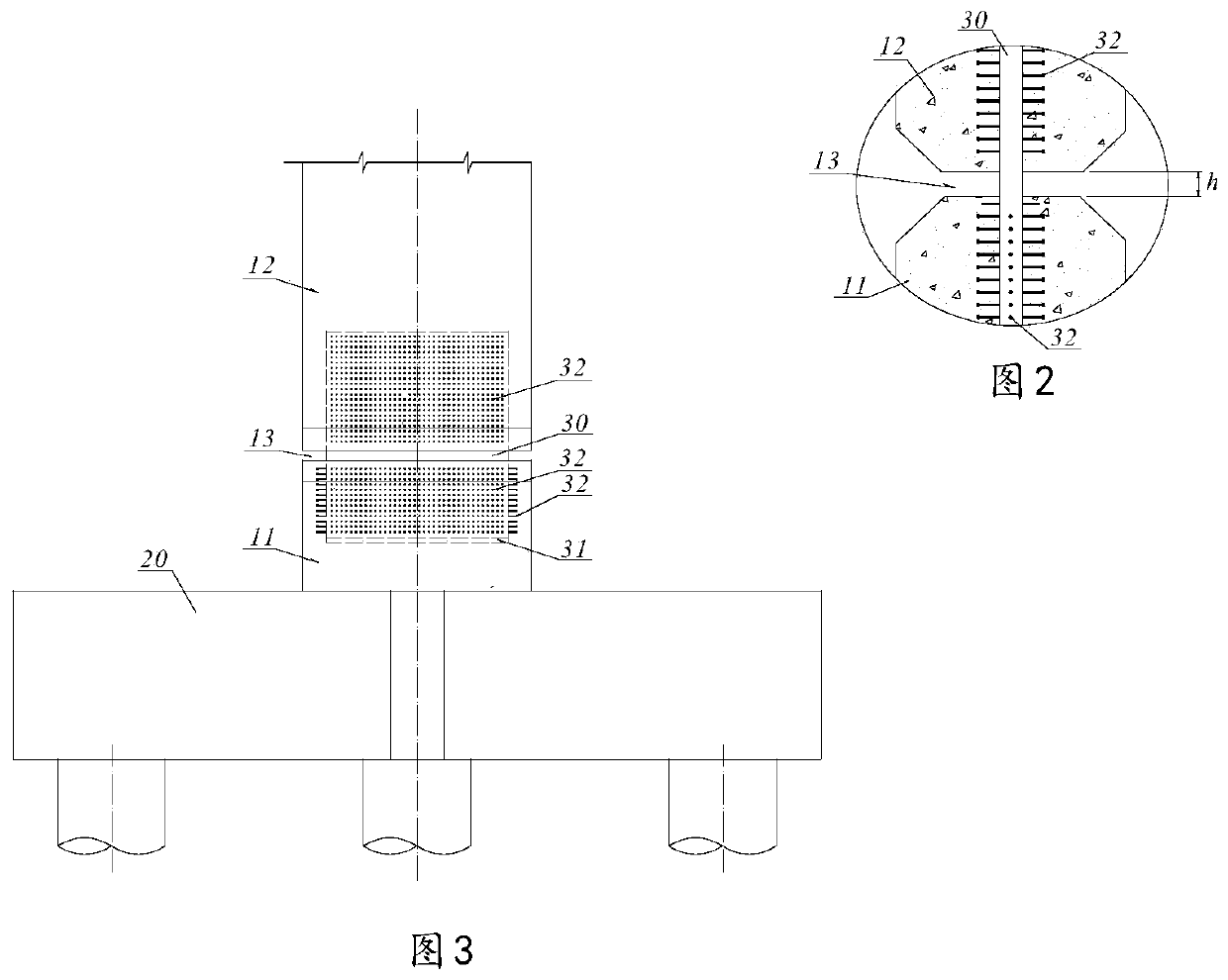

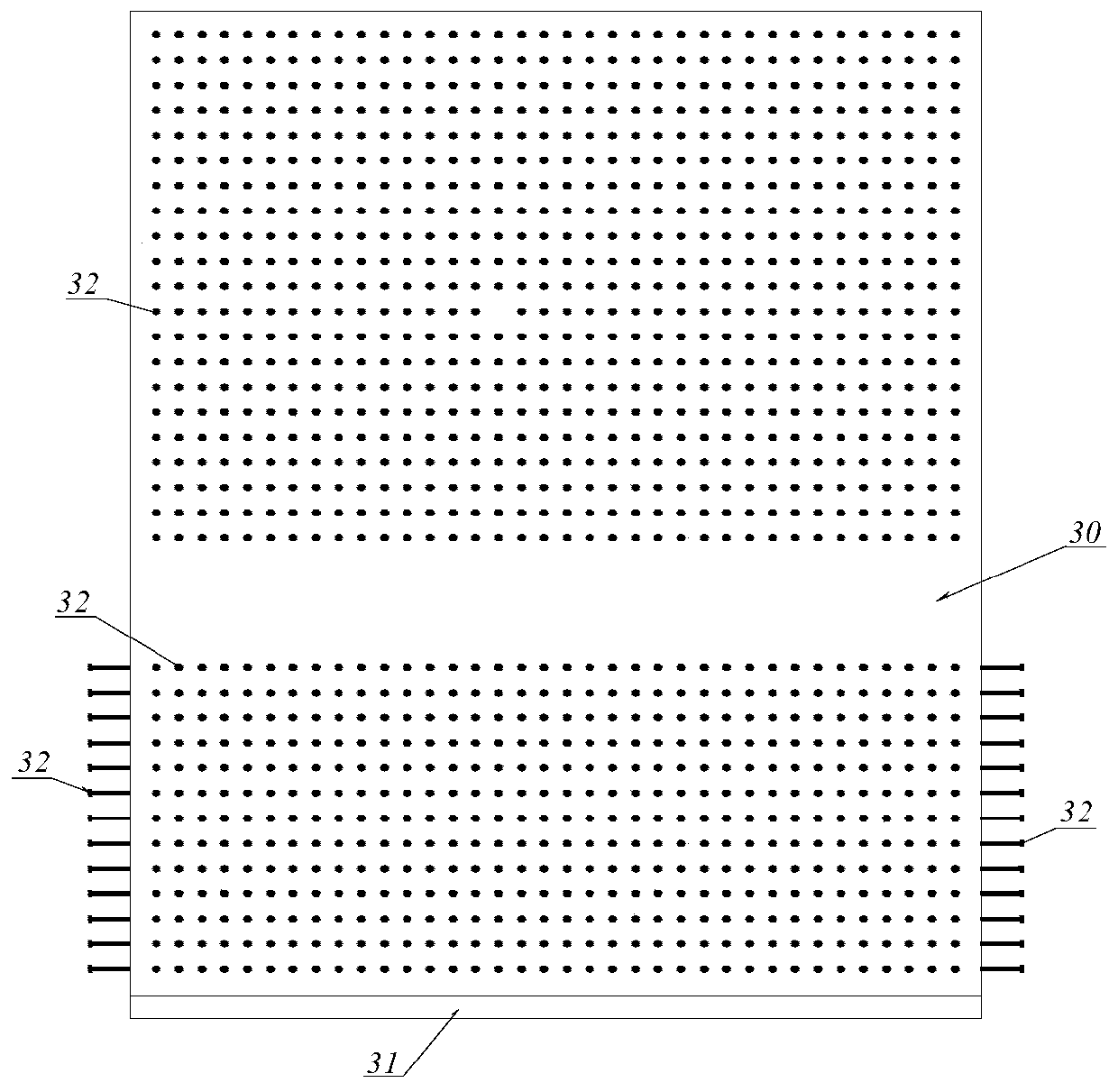

[0027] refer to figure 1 and figure 2 , the pier bottom structure of the low-pier rigid-frame bridge that can greatly reduce the bending moment of the present invention includes a bridge pier and a foundation cap 20, and the upper and lower ends of the bridge pier are respectively consolidated with the bridge girder and the foundation cap 20. The pier is broken into two sections, the upper pier 12 and the lower pier 11 adjacent to the bottom of the pier, and an annular seam 13 is formed between the corresponding end surfaces of the upper pier 12 and the lower pier 11 . Between the upper pier 12 and the lower pier 11, a steel plate hinge bearing vertical axial force is arranged, and the steel plate hinge vertically extends into the upper pier 12 and the lower pier 11 and is consolidated therewith. refer to image 3 , there is an annular seam 13 betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com