Self-walking type shield tunneling machine

A self-propelled, shield machine technology, applied in the direction of shaft lining, tunnel lining, underground chamber, etc., can solve the problems of tediousness and increase of project cost, so as to improve economic benefits, reduce workload, avoid tediousness and waste of manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

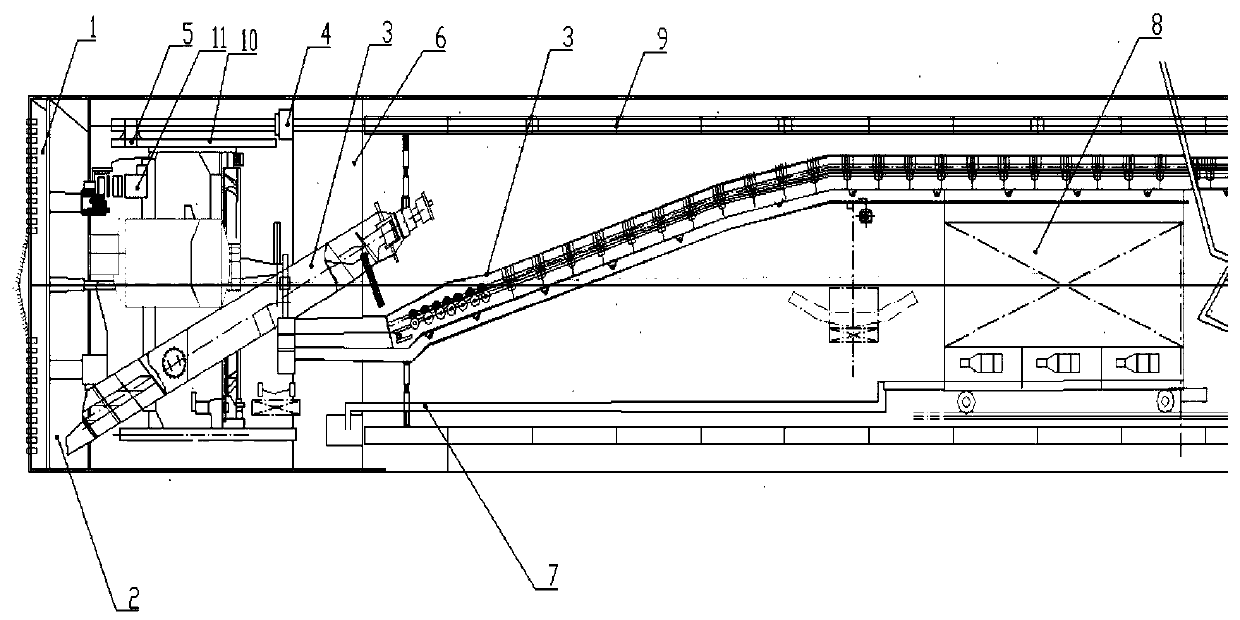

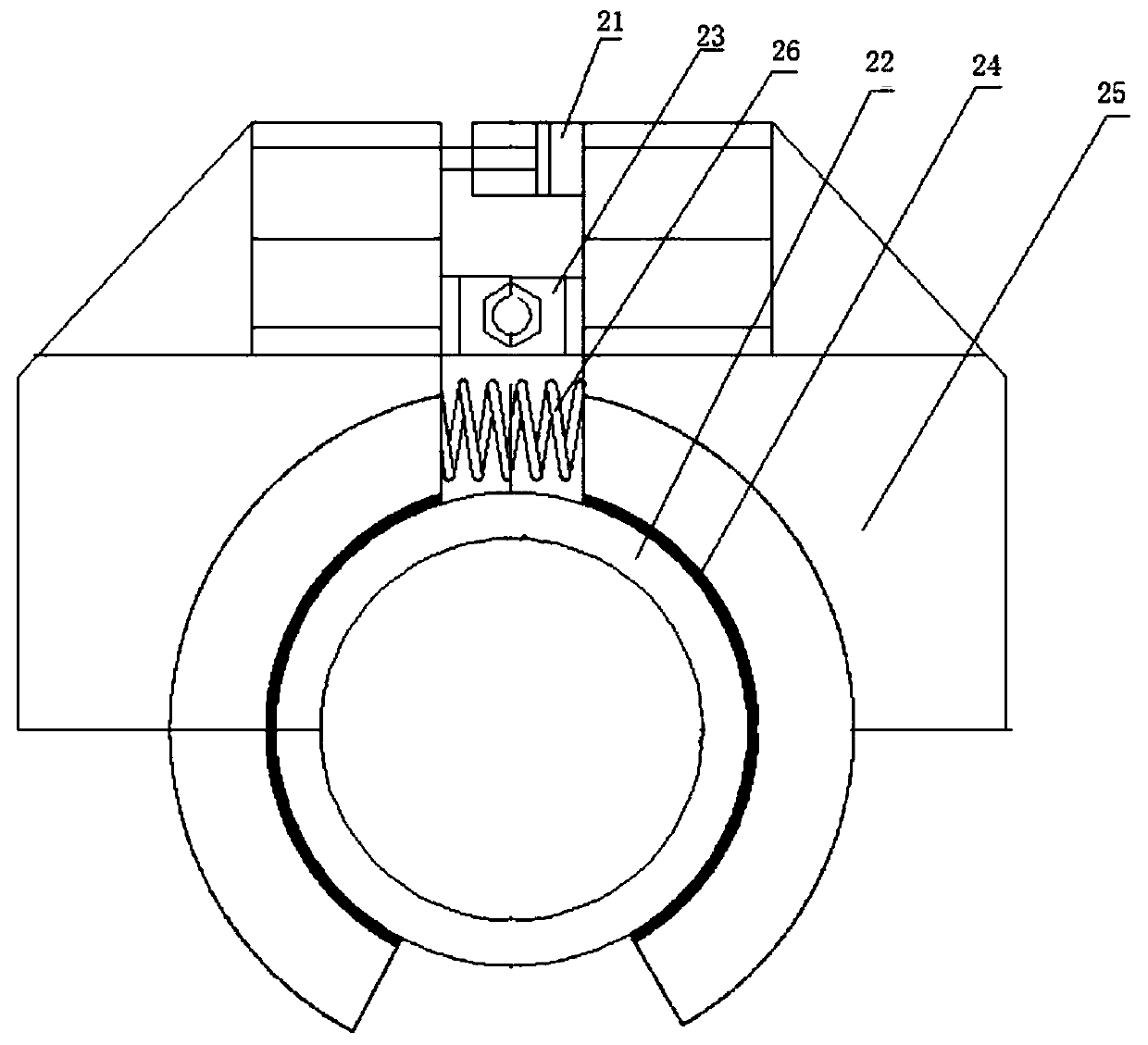

[0030] refer to figure 1 and figure 2 The present invention is a self-propelled shield machine, which includes a cutting and stirring structure 1, a cutter head power structure 2, a mud inlet and discharge structure 3, a pipeline sliding form casting structure 4 and a self-propelled structure 5 arranged in the front shell; The cutting and stirring structure 1 includes a cutterhead structure for cutting soil, a stirring rod connected to the cutterhead structure, and a compartment plate, and a sealing soil for collecting cutting rock and soil is formed between the cutterhead structure and the compartment plate bin, the stirring rod is used to stir the cutting rock and soil in the sealed soil bin when the cutter head structure rotates; the cutter head power structure 2 includes a reducer, a power box pinion connected with the reducer and the The large gear connected to the pinion of the power box; the mud inlet and discharge structure 3 includes a screw conveyor with an entranc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com