A parallel self-reset high-efficiency buffer brake

A technology of self-reset and retraction machine, which is applied to the muzzle accessories and other directions, can solve the problems of high price of self-reset and retraction machine, unsmooth retraction and return movement, and difficult to use in simple occasions, so as to facilitate processing and manufacturing. And maintenance, not easy to change, the effect of stable buffer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

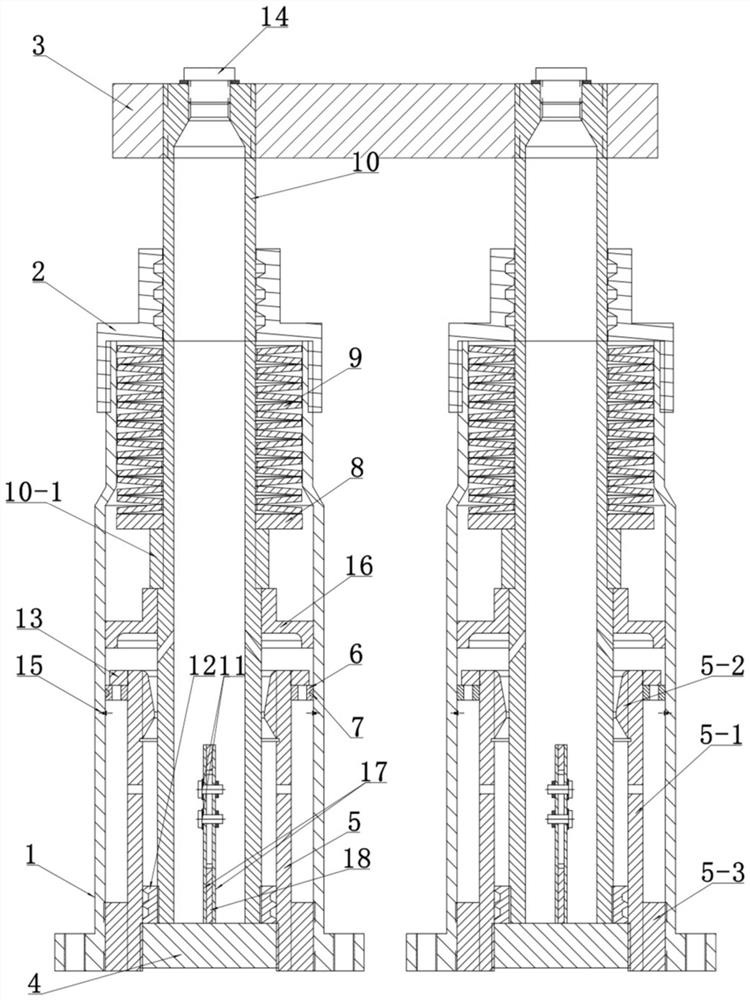

[0019] combine Figure 1 to Figure 4 , a parallel self-resetting high-efficiency buffer braking machine of the present invention includes a connecting rod 3 and two identical buffer braking mechanisms, the two buffer braking mechanisms are symmetrically arranged, and one end is connected through the connecting rod 3.

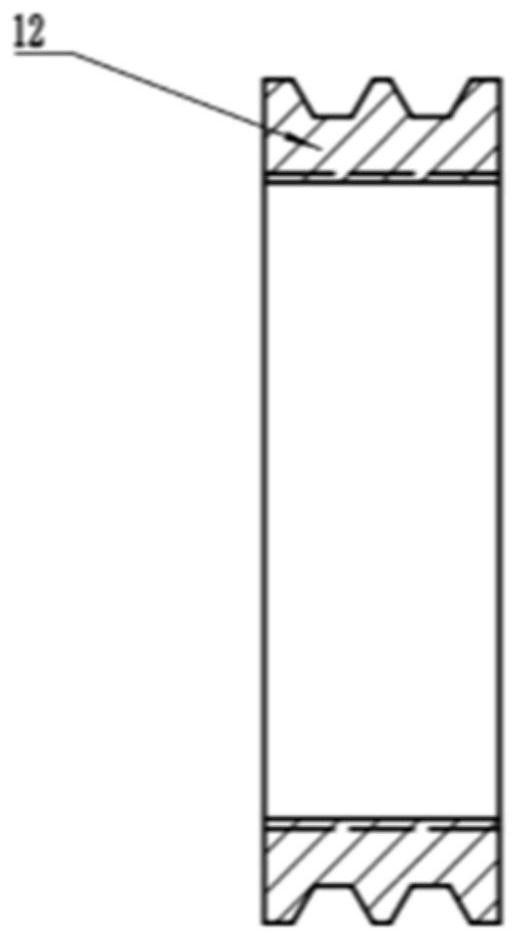

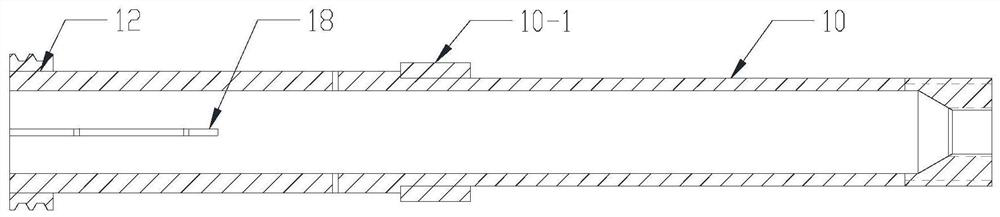

[0020] The buffering and retreating mechanism includes a shell 1, an end cover 2, a rear end cover 4, an outer cylinder for retreating 5, a return control ring 6, an annular spring seat 8, an inner cylinder for retreating 10, and a sealing ring for the end cap of the inner cylinder for retreating 12. Sealing ring 13 of outer cylinder end cover, sealing thread plug 14, ring seal 16, first friction plate 18, two limit bolts 11, two return stopper latches 15, several disc springs 9 And two second friction plates 17.

[0021] The shell 1 is cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com