Automatic overhead line deicing robot

A robot and overhead line technology, which is applied in the field of automatic overhead line deicing robots, can solve the problems of high-voltage line operation safety threats, high-altitude operation risks, and easy occurrence of electric shock hazards, etc. Avoid dangerous effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

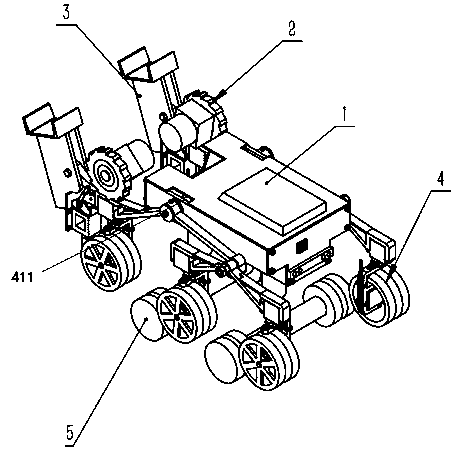

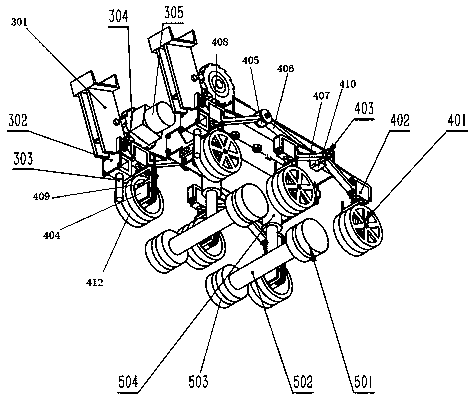

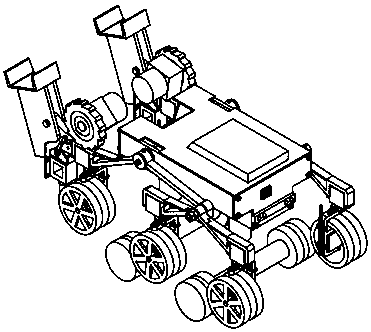

[0032] Example figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown in , an automated overhead line deicing robot includes: a base 1, a walking part 4 is installed on the side of the base 1, an auxiliary walking part 5 is arranged on the lower part, a power supply module and a remote control module are arranged inside, and an observation module is arranged on the upper part. camera module;

[0033] The power supply module provides power for the entire robot. The remote control module receives remote commands to control the overall movement of the robot. The remote control module can complete the data transmission and command actions with the remote monitoring center by setting the GPRS communication module, WIFI module or Zigbee communication module. The camera module observes the surr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com