An automatic deicing device for naval artillery

A artillery and automatic technology, applied to attack devices, ships, ship weapons, etc., can solve the problems of high energy consumption and low deicing efficiency, and achieve the effects of low energy consumption, manpower saving and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

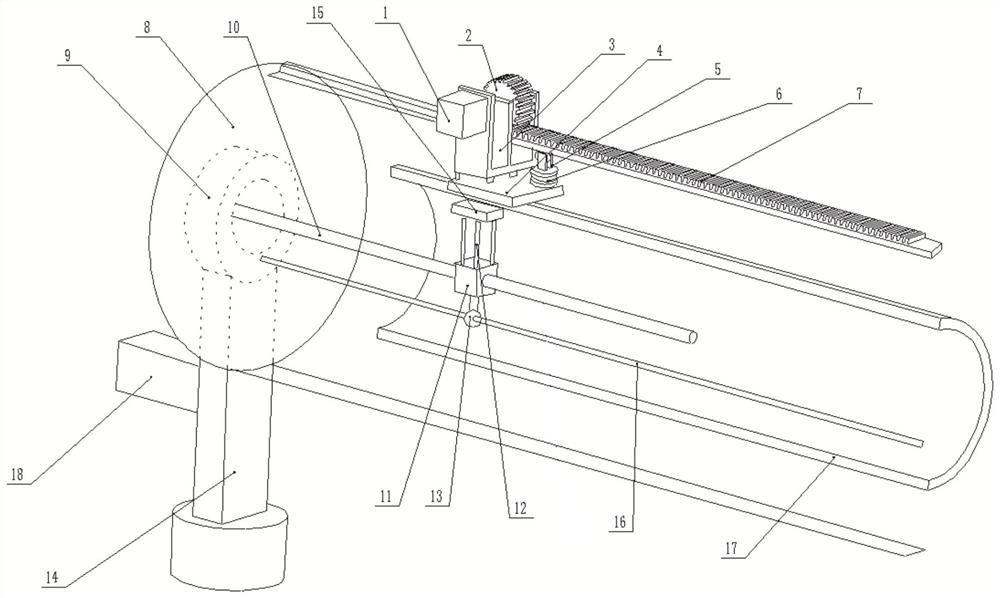

[0023] In a typical implementation of the present invention, this embodiment discloses an automatic deicing device for naval artillery, including a rotating mechanism, a first linear motion unit and a second linear motion unit, the first linear motion unit and the second linear motion unit The two linear motion units are all connected to the rotary mechanism, where the rotary mechanism is a device capable of rotating around a fixed axis, the first linear motion unit is connected and drives the first coil 4 to move axially outside the gun barrel 17, the second The linear motion unit is connected and drives the second coil 15 to move axially inside the barrel 17; the second linear motion unit is connected to the rotation axis of the rotation mechanism, and the first linear motion unit is connected to the rotation mechanism away from the rotation axis , so the rotating mechanism drives the first coil 4 and the second coil 15 to move along the barrel 17 when rotating.

[0024] Her...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com