A kind of anti-icing protective coating with high weather resistance and preparation method thereof

A protective coating and high weather resistance technology, applied in coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve problems such as high corrosion, inability to apply new technologies, poor anti-icing effect of hydrophobic coatings, etc., to achieve Lower freezing point, excellent snow melting and deicing effect, and avoid freezing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

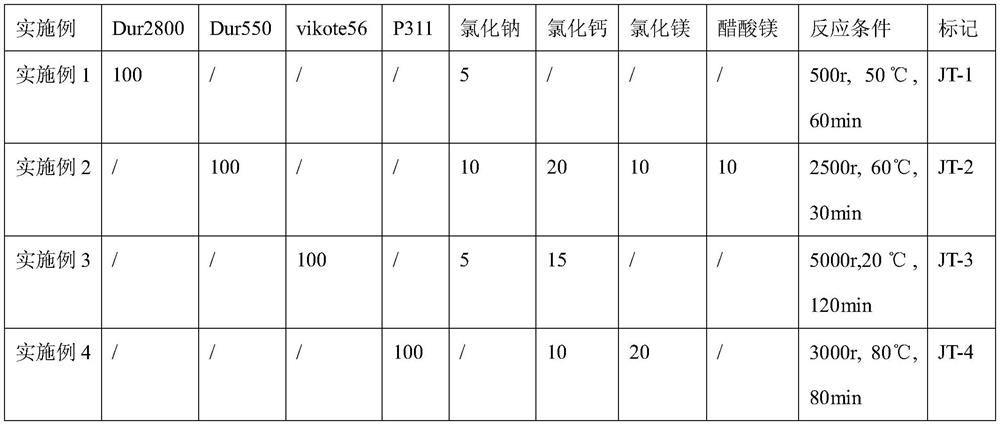

[0036] Add the snow melting agent to the resin components (non-curing components) of different high weather resistance polymer-based protective coating products, disperse at a high speed of 500-5000r / min, stir at 20-80°C for 30-120min, and obtain the resin group containing the snow melting agent When in use, mix and stir according to the ratio of the resin component (deducting the deicing agent) and the curing component provided by the commodity to obtain a high weather resistance polymer-based protective coating, which is marked as JT-1, JT-2, JT-3, JT- 4.

[0037]

[0038] (2) Preparation of nanoparticle dispersion solution

Embodiment 5-7

[0040] In a stirring environment, add highly hydrophobic and fast-dispersing nanomaterials into the dispersion solvent, and disperse at room temperature at a high speed of 1000-5000r / min for 10-30min to obtain a nanoparticle dispersion solution, labeled as Nano-1, Nano-2, Nano- 3.

[0041] Example DNS2 DNS3 DNZr-1 acetone ethyl acetate Butyl acetate Reaction conditions mark Example 5 0.2 / / 100 / / 5000r, room temperature, 10min Nano-1 Example 6 0.5 0.8 / / 50 50 2500r, room temperature, 20min Nano-2 Example 7 / 1.0 1.0 50 / 50 1000r, room temperature, 30min Nano-3

[0042] (3) Preparation of high weather resistance anti-icing protective coating

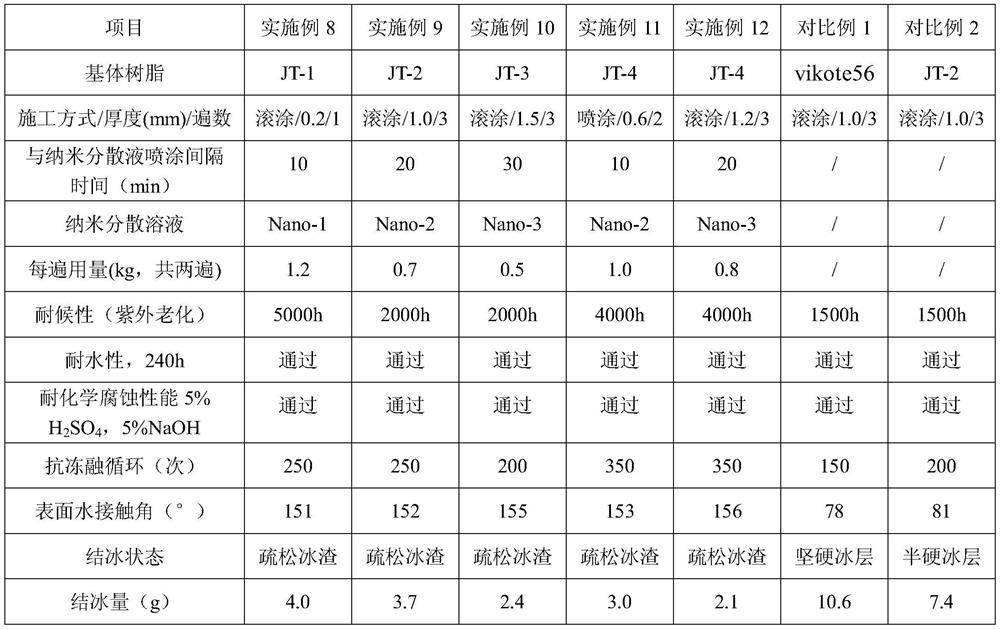

Embodiment 8-12

[0044] Mix and stir evenly according to the ratio of the resin component (deducting deicing agent) and curing component provided by the paint manufacturer, and apply the polymer resin system JT-1 containing deicing agent by roller coating, spraying, etc. according to the construction process provided by the manufacturer, JT-2, JT-3, JT-4 form an organic coating according to the thickness of the coating; 10-30 minutes after the last construction, the nano-dispersion solution is sprayed twice vertically and cross-sprayed, and the solvent evaporates to form a nano-hydrophobic layer; the whole system is cured for 7 days to form a highly weather-resistant and anti-icing protective coating that integrates waterproof, anti-corrosion, snow melting and deicing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com